“All you have to say is this…‘I don’t care what it costs.’ And then, of course, you’ve got to really mean it, which, of course, no one ever does.”

— Quote from 1999 movie “Blast from the Past”

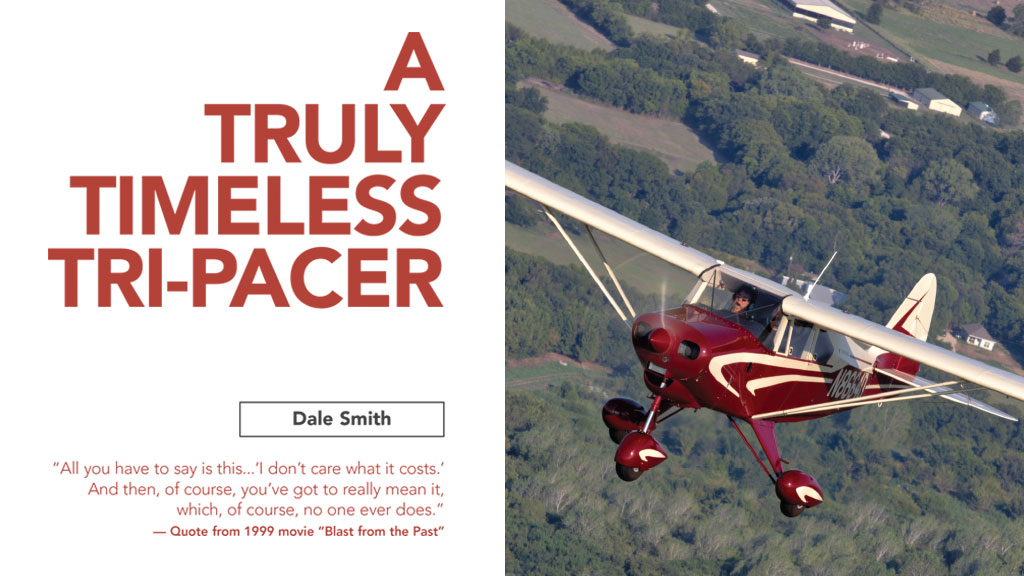

When it comes to PA-22 rebuilds, there are good Tri-Pacers and there are great Tri-Pacers, but there is only one “truly better than the day it was built” Tri-Pacer. Here’s the love story behind it.

The one thing I like most about attending events like Sun ‘n Fun and Oshkosh AirVenture is the opportunity to just wander around and look at the airplanes. Walking the grounds with the sun barely up and the dew still dripping from wings, I sometimes am lucky enough to come across an airplane with a story that just has to be told.

Such was the case when I happened upon my friend Darin Hart, owner of American Legend Aircraft Company on a sunny Wednesday morning. He was busily wiping Lakeland’s “liquid sunshine” off of the most amazing looking Piper Tri-Pacer that I have ever seen. It was like stepping back some 60-years to a spring morning in Lock Haven, Penn. just after the pristine PA-22 rolled off the assembly line.

“This is without a doubt the nicest Tri-Pacer in the world,” Hart said. “And it’s not just because we rebuilt it. It’s as close to brand new as you’re ever going to find. And it should be considering the owner spent nearly $250 thousand dollars on it.”

While he had me at “the nicest Tri-Pacer in the world,” the thought that the owner had spent “nearly $250 thousand” U.S. dollars having it rebuilt meant this was a story that had to be shared.

You Can’t Put a Price on Love

“A lot of people say I’m nuts and that I’ll never get my money back,” explained the Tri-Pacer’s proud owner, Mark Wyant. “But, I’m okay with that. That’s not what this is all about. This is not just any airplane to me. It represents a lot of great memories and a very special part and person in my life.”

Bringing back great memories and paying homage to his father are the two reasons why Wyant began the project to rebuild his beloved Tri-Pacer in the first place. But to understand how we got where we are today, we have to go back to 1974 when Wyant was an eighth-grader in Dallas.

“When you’re going to school in Garland, Texas if you don’t play football, there’s not much left for you to do. I was too skinny for football, so I spent a lot of time reading,” Wyant said. “I got a copy of Anyone Can Fly by Jules Bergman and I was hooked. I read that book three or four times.”

“It was all about Bergman learning to fly in a Piper Tri-Pacer. It was full of Tri-Pacer stories and pictures and that was my introduction and motivation to learn to fly,” he said. “And, of course, I fell in love with the Tri-Pacer from the book.”

When he turned 15, Wyant started taking flying lessons at Dallas’ Addison Airport (KADS) in a Cessna 150.

“Then my dad and I got the idea of buying a Tri-Pacer together,” Wyant said. “We started looking around for a nice one. Turned out there was one for sale at Addison Airport where I was learning to fly. My dad and I went over to look at it together.”

“I just fell in love with it right there and we ended up buying it for $5,000. Later that night I snuck back into the hangar where it was and my best friend Jon Contreras just sat in it with the master on and all the lights flashing,” he said. “I wouldn’t have been more proud of it than if it was a new Learjet.”

“I finished up my license in 8664 Delta at nearby Rockwall Airport. It was a lot more fun to fly than the 150,” he said. “Two months after I got my license I flew my mom and dad a thousand miles up to Indiana to see my grandmother. My parents were very trusting – neither of them were pilots. I even took my grandmother for a ride back in the summer of 1976. It doesn’t seem like that long ago.”

Wyant said that during his senior year in high school he took a lot of his friends up flying and that the guys on the football team were now looking up to him – literally.

“I was suddenly the big man on campus, so to speak,” he said. “Not many high school seniors have their own airplanes. The Dallas Morning News even did an article on me when I got my license on my 17th birthday.”

While Wyant loved his Tri-Pacer, once he was out of high school, his head was turned by airplanes that were just, well, “sexier.” Youth has a way of doing that to you.

“We had it for about a year then sold it,” he said. “You always want to go further and faster. I went on to become a CFI and fly freight at night. After a while, I went to work flying for American Eagle and finally as a 767 pilot for American Airlines.”

8644D: Gone but Not Forgotten

Wyant spent a total of 22-years flying for American, but while he loved his job, when the opportunity came along to take an early retirement from flying the line, he took it. And while he had a logbook full of hours in a wonderful assortment of aircraft types, he never forgot about his first love.

“I always knew my Tri-Pacer was out there. I kept checking on the FAA registry for it and fortunately nobody ever changed the N-number,” he said. “That airplane just meant so much more to me than tubing and fabric. It has a history with me – a short one, but a very meaningful one in my life.”

“My dad passed away some 19-years ago and he was always very supportive of my flying. That meant so much to me. It was one of those things that he and I shared a great attachment to,” Wyant said. “My dad couldn’t fly because of poor hearing and eyesight. But that didn’t stop him from loving time in the cockpit. He loved to fly. This right seat was his whenever we flew together.”

“As time went on, whenever we would buy another airplane: Whether it was the Mooney, Bonanza or the Aerostar – when we flew together we’d laugh and say, ‘It sure beats the Tri-Pacer.’ But, that little airplane meant something really special to us,” he said. “That’s why I had to get this airplane back.”

As luck, or maybe fate, would have it, Wyant’s first love was living not far away in Tyler, Texas, which is about 80-miles from his home in Dallas.

“I had searched out the owner’s phone number and called to see if he was willing to sell. His answer was no,” Wyant said. “About a year later, I called and asked again. Same answer. Another year later, I decided that I was going to give it one last shot so I called and offered him twice what it was worth. That got his interest.”

As Wyant happily admits, he ended up paying “stupid money” to get his beloved Tri-Pacer back. But, as we all know, when it comes to settling affairs-of-the-heart, some things just can’t be measured in money.

She Didn’t Look at All Like Her Yearbook Photos

“When the owner had finally agreed to sell the Tri-Pacer he had described it as being in ‘excellent condition and always hangared,’” Wyant said. “When I arrived at the airport I found that, yes it was in a hangar alright, but leaning up against the hangar was more like it. It was horrible looking. It hadn’t been out of that hangar for a long time.”

Anyway, Wyant was too deep to turn back now so he bought 8664 Delta and flew her back to Addison airport. While many an owner would have been totally disheartened by the sad condition his high school sweetheart was in, he saw it as an opportunity to not just bring his beloved Tri-Pacer back to the way he recalled, but make her even better.

“That’s when I contacted Darin Hart at American Legend Aircraft Company. When I decided to do a restoration, I didn’t want just any restoration – I wanted to make this Tri-Pacer as good, or better than the day it left the factory in Lock Haven,” Wyant said. “You can’t find many people that can do that.”

And who better to do a “factory fresh” restoration on the Tri-Pacer than a company that currently makes factory new “Cubs?” Which is precisely what the craftsmen at American Legend Aircraft Company have been doing since 2004 with their popular Legend Cub series.

Along with manufacturing new Legend Cubs, Hart has become a legend of sorts amongst the Piper community with the exceptionally high quality aircraft rebuilds that come out of his facility in Sulphur Springs, Texas.

“American Legend Aircraft Company actually started from our work doing high-quality restorations on Cubs. I think we’ve won five or six Lindy Awards at Oshkosh over the years,” Hart said. “People call us on a weekly basis wanting to do a restoration on a Cub, Champ or Tri-Pacer, but they have to be really serious for us to do the job.”

“For us just to pull the covering off and replace it, without doing anything else will take 400 man hours and cost $38,000,” he said. “And that’s not sandblasting the frame or replacing any hardware. That’s just the covering. The price scares a lot of window-shoppers away.”

Hart said that when Wyant called him about rebuilding 8664D, his first response was that the airplane wasn’t worth the cost of just stripping and recovering it.

“But then he explained the story behind it, I could tell that this wasn’t really about the airplane to Mark, it was much more,” Hart said. “I am very proud that he put his trust in us to do the work for him.”

You want it when??

While Wyant was more than happy to pay American Legend Aircraft Company’s premium price for the work, there was one catch, if you will.

“We started the project in late January and Mark said he had to have it at Oshkosh that July. So we had inside of six months to rebuild the Tri-Pacer,” Hart said. “I think he was a bit surprised when I said that would be no problem at all. We are a production shop so we are used to getting airplanes in and out quickly. We don’t have room or time to keep projects sitting around for years.”

While the timeframe was not out of the ordinary, the team didn’t have any time to waste. Hart said that a big part of what sets an American Legend rebuild apart from another is the research and detail they put into a project.

After stripping the airplane and inspecting the steel tubing, wood ribs and components they set about repairing and replacing whatever needed doing. All-in-all, Hart said it was in serviceable condition for a 60-year old airframe.

“We took the frame down and sandblasted it clean then replaced what metal tubing wasn’t up to our standards,” Hart said. “Its essentially a new airframe. Then we replaced every nut, bolt, pulley and cable. Everything is brand new.”

“Univar Aviation Corporation has a tremendous stock of parts for these classic old Pipers so it was easy to buy practically everything we needed,” he said. “Control surfaces, ribs, flying wires, struts, the entire exhaust system: even the fairings that go around the struts – things you think you’d have to fabricate you can buy form Univar.”

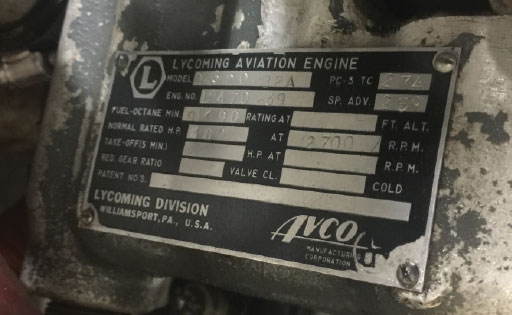

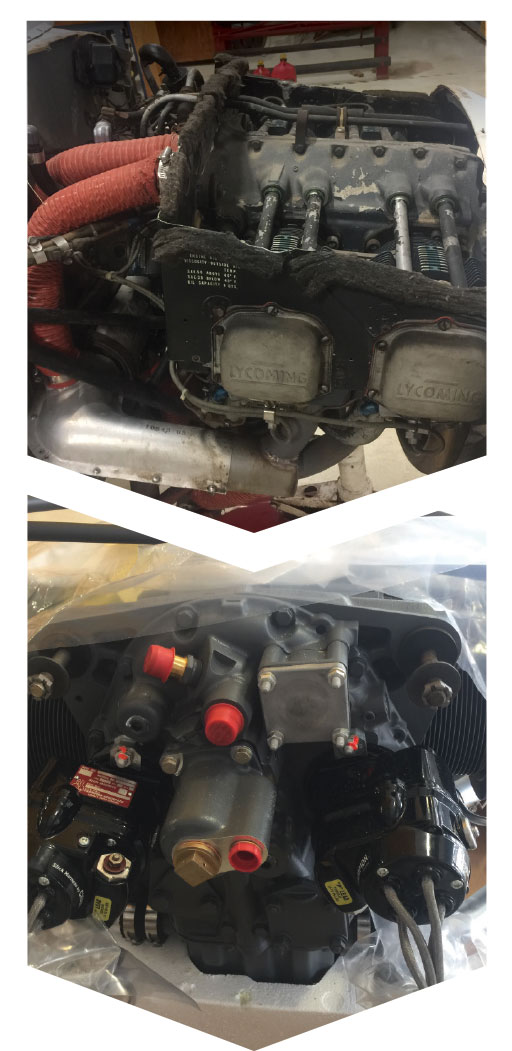

Hart said that instead of overhauling the 160-horsepower Lycoming engine, Wyant wanted a brand new engine because that’s the way it left the factory in 1958.

Speaking of achieving that factory look, Hart said that one detail that many restorers overlook is the painstaking replication of the original factory stitching.

“Darin went back and found the original build sheet on this airplane to find out how they laid the fabric on, how it was stitched and even the location of the ‘dollar patches,’” Wyant said. “The way they stitched it all is exactly to the original Piper specifications they published in their production manual. Everything is as authentic as it can possibly be.”

“Also, most people don’t realize that the back half of the baggage compartment was originally made of canvas cloth,” he said. “Most have long since replaced it with the same fabric as they use to cover the exterior, but that’s incorrect. We found original OEM canvas and put it back where it belonged: including the strap that holds the tow-bar in place.”

Back to the Future

Of course you can’t put all that work into making every detail factory correct and then rattle-can any old paint scheme on. So, while Wyant liked the yellow and white scheme the Tri-Pacer had when he flew her as a teenager, it wasn’t as she left the factory.

Since they already had Piper’s dimensional drawings of exactly where the stripes and N-number laid out on the airframe, Hart contacted Piper Aircraft restoration expert Clyde Smith a.k.a. “The Cub Doctor,” to find out the exact colors the factory would have used in 1958.

“He knew by the serial number what the exact colors were for that airplane,” Hart said. “Santa Fe red and Daytona white. It’s a very classic combination for Pipers.”

“The only difference in the factory paint and what we used was that ours is shiny, while the factory originally used a matt finish, We felt the shiny paint would hold up better and be easier to clean,” Wyant said. “All of the interior fabric is also Piper spec. Turns out it was the same upholstery that was originally from a 1958 Mercury Marquis automobile, which we were able to find from a supplier.”

Hart said that while finding the original material to redo the upholstery was easy, replacing the original batting material used for cabin “sound-proofing” was much more labor intensive. But, again, if it was done at the factory, it was replicated in Mark Wyant’s Tri-Pacer.

While it’s crystal clear that Wyant and American Legend spared no effort, nor expense, to make the Tri-Pacer as 1958 as possible, that type of originality won’t work when it comes to an airplane that’s actually going to fly in today’s airspace. Especially with the 2020 ADS-B mandate on the horizon.

N8664D Goes “NextGen”

So how do you keep an airplane looking like it’s right out of 1958, while having all the avionics capabilities Wyant needs to safely navigation around Dallas’s busy airspace? Well, turns out a bit of visual trickery works every time.

before and after.

“My friend Jon that had sat with me in the airplane the night I bought it in 1976 and I took the panel rework on as our project. All of the instruments were sent to Keystone Instruments in Lock Haven where they were rebuilt and the faces were repainted in the original off-yellow color,” Wyant said. “Most people think they’ve yellowed with age, but they were originally that color so that they would show up better when lit by the red cabin light.”

Wyant was even able to locate and reinstall the original Piper ashtray that came in the Tri-Pacer. Not that there’s any smoking allowed.

While he was able to add in many OEM details, when it came time for equipping the Tri-Pacer with the mandated new-generation avionics, Wyant was faced with a more difficult challenge and that’s where the high-tech trickery comes in.

“I wanted anyone looking in the cockpit to see an airplane the way it was in 1958, but I also needed avionics that give me the same safety and capabilities I have in my Citation Mustang,” he said. “To accomplish what I wanted, Jon took an original Narco Omingator and a VLR-3 low-frequency receiver and cut them down so that they were about an inch and a quarter deep. We needed several “donor” radios to accomplish this and it took more than two months to pull it off.”

“We mounted them to a false panel piece that looks just like they are original. They even light up when you turn them on,” Wyant said proudly. “But, when you remove the faceplate, you’ll find a brand new Garmin GTN touch screen 750 and a Garmin GTX 345 ADS-B Out/In transponder. As it turned out once installed in the panel, the height of the 750 and 345 were the same as the Omnigator and VLR-3 units so it’s the perfect match.”

Another significant upgrade Hart and his team performed on the Tri-Pacer was the switch from the OEM installed BF Goodrich brakes to much more modern and reliable Cleveland wheels and brakes. In addition, they replaced all the old incandescent exterior and interior lights with new LED lighting.

“Now I can leave all the strobes and landing lights on all the time, which is good for safety,” Wyant said. “For additional reliability, we also upgraded to a new lightweight, Sky-Tec starter and replaced the old unit with a new 60 AMP alternator.”

What Goes Around, Comes Around

Wyant said that true to their promise, the team at American Legend Aircraft Company completed the “brand-new” Tri-Pacer in time for Hart to fly it to Oshkosh AirVenture 2017.

“We put just about 1,800-hours in the total rebuild,” Hart said. “I have to say that it really turned out great. And that it’s a very nice flying airplane. I’ve flown it to Oshkosh and to Sun ‘n Fun in Lakeland and it’s a very comfortable cross country airplane.”

“Although, I can see why Piper quit making them. They are very complex airplanes and they couldn’t compete with the Cessna 172 for production,” he said. “In particular, the control cables being fully interconnected were very sophisticated and labor-intensive to install. Compared to the Piper Cub, the Tri-Pacer is probably twice as complex to put together.”

No matter how complex or how much it ultimately cost, Wyant says that he is thrilled with how his beloved Tri-Pacer turned out. “I believe it’s the finest example of a Piper Tri-Pacer in the world,” he said proudly. “I don’t mean that as any type of hyperbole, but I truly believe that we achieved our goal in every way.”

So, you have to ask, now that the Tri-Pacer is done, what are his plans for it? “Back in 1958 people thought they were dumpy looking and nicknamed them ‘flying milk stools,’ but today, I think they’ve become retro,” he said. “My son is 13 and he’s a fan of the way it looks and flies. I’m slowly teaching him to fly the Tri-Pacer and he’s loving it.”

“Today, it lives in my hangar next to my Citation and my hangar/office is right inside. Every day when I walk in I take an minute to give her a little pat,” Wyant said. “This is not just an airplane to me, it represents a lot of great memories and a very special part of my life and the people in it. There is no question that I own the world’s most expensive Piper Tri-Pacer and I’m totally fine with that.”

To see the full gallery of photos of the rebuild, go to avmdevelop.wpengine.com/tripacer