When there is a market downturn, business jet aircraft owners look to breathe new life into their asset. Or, instead of buying new, they might consider a used aircraft and then take it in to personalize it. Air medical operators — so important in the current health crisis — are actively considering future projects. We talked to some key players in the mod market to see what interesting modifications they have recently made.

Ff there was ever a time for mods, it’s now. Refurbishing a used airplane is a bargain compared to buying a new one.

Modifications come in all shapes and sizes. Air purification is popular at the moment. Re-engining mods are also selling. And interior work to boost comfort and convenience is always in demand. More specialized, air medical conversions are particularly relevant at this time.

Sales of new aircraft will be “a little bit muted for a while” but there may be a “bump” in the purchase of used planes, predicts Marc Drobny, president, business aviation, with StandardAero. The downturn encourages people to hang on to their airplanes longer and to spend money to breathe new life into them or to buy a used aircraft and make it look brand-new.

As the virus affects all facets of life, “we are seeing people don’t really want to ride the airlines,” observes Jim Allmon, president and CEO of Blackhawk Aerospace, which designs and sells engine replacement programs. If they can afford it, they are buying airplanes, especially turboprops, which probably have a little better optics as corporate aircraft than jets, he says. A lot are first-time buyers, pushed into the market by the virus, but others are moving up from piston-engine airplanes. While business is off from 2019, people are still ordering engine upgrades. “It’s better than we expected it to be,” he says.

StandardAero

“We can do anything…to the inside of a plane,” Drobny, says, including seating, storage, cabinets, carpets, sidewall materials, galleys, and lavs. As far as the exterior goes, “we’re not going to lengthen the fuselage” but can do painting and winglets.

StandardAero does air purification mods. “We’ll see if this turns out to be of passing interest or if it turns into a fad,” Drobny says. The MRO uses the ACA air purification system, which interfaces with the existing heating/ventilation system. It works electronically to create positive and negative ions from the hydrogen and oxygen molecules in the water vapor present in the air, according to ACA. These ions cluster around micro particles, mold spores, viruses, and bacteria, effectively “inactivating” them, ACA says.

The MRO also installs winglets. For a couple hundred thousand dollars you can decrease fuel consumption by five percent per hour, Drobny says. StandardAero has performed this upgrade on multiple Falcon types, Learjets, Citations, Hawkers, and Challengers.

Air Medical

Hillaero Modification Center, Elliott Aviation, and StandardAero do air medical mods. Hillaero recently completed a fleet of King Air B200 conversions for use in Alberta. Each cabin is equipped with rotating medical crew seating, a parallel overhead track system with “no-tools” sliding adapters, and sidewall-mounted medical gas outlets, says company president, Carol Swigart. This configuration also features a single-patient LifePort PLUS unit — the base and stretcher system — and an aft storage compartment outfitted with shelves and a cargo net to hold all carry-on equipment securely for taxi, takeoff, and landing. “A TDFM radio in the cabin sidewall provides an effective conduit for air-to-ground medical communication,” she says.

Typically we won’t have to strengthen the flooring or substructure unless it’s a heavier mod, explains Adam Doyle, paint interior sales representative with Elliott Aviation. He recalls a Hawker 800XP air medical mod that involved removing the left-hand forward galley and installing it in the back of the plane. This made it easier to get patients in and out of the aircraft, he says. The company reinforced the aircraft structure to support that function in its new location.

The MRO also can add communications devices in the aft of the airplane. Some operators have very specific ways of cutting certain individuals on and off and of controlling what’s said and heard through various communications, Doyle says.

StandardAero also does air medical mods. The Hawker 800 is a pretty popular platform, Drobny says. The airplanes tend to be 10 to 20 years old. Work might involve cutting a new door, installing electrical connections, and adding support equipment.

By contrast, 25 to 30 percent of Hillaero’s air medical mods involve new airplanes, Swigart says. “Some hospitals may have made a significant investment and may want new or newer airframes.” Some operators, for example, might buy a King Air in a cargo configuration — with no seating — and start from there.

What’s Involved

The conversion of a used business aircraft starts with the client’s selection of the stretcher platform they’re going to use – from one of the air medical suppliers such as Spectrum Aeromed or LifePort, Swigart explains. This structure, to which the stretcher is attached, supports the loads to hold the patient securely during flight. Medical supplies such as oxygen can also be accessed through the bottom of the base.

Hillaero develops the floor plan, including items such as seating and storage cabinets, to operator requirements. One Hillaero specialty is an overhead track system to help position medical equipment, such as ventilators and defibrillators that come on and off of the airplane with the patient.

Center image shows another AAS Blackhawk XP135A install in progress.

Bottom image shows a King Air 350 during a MedEvac installation performed by AAS and Spectrum Aeromed.

AAS images.

The overhead track system consists of two parallel tracks installed in the headliner and tied structurally to the airframe, Swigart explains. The system “is substantiated to hold 25 pounds every 20 inches.” A sliding no-tools adapter enables the user to position the medical equipment directly over the patient, as needed, with a simple quarter-turn knob. A typical configuration would feature three adapters per patient location. Hillaero offers a full line of medical equipment enclosures that lock into the sliding adapters. “We have sold the entire system — including the track kit and enclosures — to other modification centers,” she says.

Elliott Aviation has modified King Airs, Beechjets, Citations, Pilatus PC-12s, and Hawker 800XPs, Doyle says. The company, for example, can reconfigure interiors, remove and replace seating, install units that hold stretchers and contain medical oxygen and air, add mission-specific avionics, modify the baggage compartment, add specialized storage space, and apply antimicrobial materials. The MRO also has made a unit that transports an ECMO system. (ECMO, which stands for Extracorporeal Membrane Oxygenation, functions like an artificial heart and lungs.)

Hillaero has converted pre-owned and new PC-12s and has supported Pilatus on parts and designs for PC-24 conversion. The company also has completed the first in a series of three HondaJets and is talking with the OEM about future direct partnerships, Swigart says. It has converted a lot of King Airs and Citations.

Conversion of a used aircraft could take six to 10 weeks, Swigart says. Designing the layout, installing the wiring and seating, custom-building the cabinets, and then painting the exterior take time. The cost of an air medical mod can range from $200,000 to $1 million.

Engine Replacement

Blackhawk Aerospace has developed programs for the King Air 90, 200, 300, and 350 series, the Cessna Caravan, Piper Cheyenne, and Cessna Conquest, the company says. It typically designs and sells upgrades, relying on its 80 dealers to perform the installations. Blackhawk has sold some 890 engine upgrade programs since opening for business in 1999. It is Pratt & Whitney’s top buyer in the non-OEM world of new turboprop engines.

It’s generally cheaper to overhaul than to replace engines but that won’t increase performance. The company’s King Air 350 program, for example, can transform a 300-knot turboprop into an up-to-335-knot “jet-performing-type” airplane, Allmon says. The company has sold about 35 King Air 350 programs since it got the STC a couple years ago.

An engine upgrade improves an operator’s mission profile, Allmon says. Some sky dive operators, for example, are grounding their big Twin Otters because they have fewer jumpers. “A lot are scaling down to Caravans and like our engine upgrade because it improves their profitability quite a bit.”

P&W also gives Blackhawk customers “core credits” for time remaining. On the King Air 350 it’s $70 per hour, which adds up to $140,000 off the top if there are 1,000 hours on the engines, he says.

How It’s Done

One Blackhawk dealer, Augsburg Air Service (AAS) in Germany, performs Blackhawk-designed engine replacements on King Air C90s and B200s, says Florian Kohlmann, managing director. Benefits include new Pratt & Whitney-warrantied engines, increased airspeed, increased rate of climb, increased single-engine service ceiling, decreased time and fuel to climb, lower maintenance cost, and increased resale value, according to Blackhawk.

Some of the steps that AAS performs in re-engining the King Air C90 under Blackhawk’s XP135A program include removing the original Pratt & Whitney PT6A-21 engines; non-destructive testing of the engine truss mounts; installation of new P&W PT6A-135 engines provided by Blackhawk; removal and replacement of the special oil used during engine storage; modifying the flight instruments or installing Blackhawk gauges, optionally; and modifying the starter, as required. Kohlmann also notes the Enhanced New-Engine Warranty of 2,500 hours/5 years with prorated coverage to the 3,600-hour TBO. The 2019 total cost of the AAS King Air C90 engine replacement upgrade under Blackhawk’s XP135A program was about $770,000.

The engine upgrade takes two to three weeks, Kohlmann says. Customers often combine an engine upgrade with a Raisbeck propeller upgrade, which would add about a week to the job, he says. Only the cores go back to Blackhawk. Some of the accessories are provided new with the new engines while others can be outsourced to overhaul facilities.

Falcon Storage Makeover

The front lav space on some Falcon 900 and 2000 aircraft is often used as a “makeshift storage compartment,” says Tracey Boesch, senior completions sales rep for Duncan Aviation. It’s “a lot like your closet at home. If you just stack and throw things in there, things aren’t tidy or organized and the space is not maximized.”

The MRO designed a conversion of this space so that it can function as a customized storage cabinet, coat closet, or a combination of the two. Duncan Aviation has modified five aircraft so far. “We capped all the lines from the toilet and built a cabinet insert that molded around the old chute just in case the next owner wants to reinstate the lavatory,” Boesch says.

“The initial Falcon 900 customer requested a large ice drawer in the bottom and a coat closet up top, but the space looks a bit like a soda bottle, so it took a bit of finagling to ensure every square inch was used.”

The initial Falcon 2000 customer requested a cold catering box storage, crew closet, upper storage and a lower drawer, as well as tasks such as a partial paint, left-hand entertainment cabinet mod, and the addition of a passenger coat closet.

These modifications, along with a full interior refurbishment, take 10-12 weeks. “It’s all new construction and each one is somewhat different and customized,” Boesch says. The job requires engineering and construction, as well as finishing and reinstallation.

Banyan images.

Auto-throttle

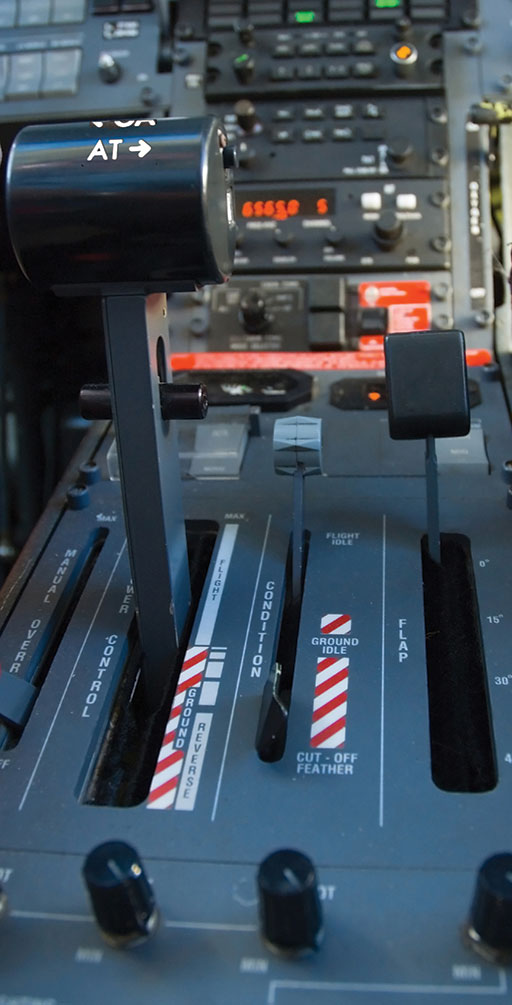

Banyan Air Service highlights its recent installation of the IS&S ThrustSense Auto-Throttle system, American Aviation Speed Cowl, and the Luminary Cabin Comfort System on a Pilatus PC-12NG. The project involved removing the interior, installing the cabin comfort system, and then reinstalling the interior, says Paul Rose, Banyan’s vice president of technical sales. The job, including an annual maintenance check, took three weeks.

The auto-throttle system helps lower the pilot workload by computing the thrust and holding selected speed/torque while implementing the appropriate temperature and torque limit protection. The system computes and controls torque during all flight phases, including climb.

The Speed Cowl system creates a more aerodynamic façade, which features a cowl inlet that captures 100 percent of the dynamic air pressure, improving engine performance. And the Luminary acoustic and thermal insulation package reduces overall cabin and cockpit noise levels by 25 percent.

LED Lighting

“If you want a system that’s cheaper than white-light-only, is easy to use, and adds a ‘wow factor,’” Elliott Technologies’ PRIZM upgrade could be the ticket, says Tim Lockerby, product sales manager with the Elliott Aviation subsidiary. The app-controllable LED-color lighting upgrade also enhances the airplane’s resale value, he says.

There are millions of colors to choose from. You can customize the colors of the upwash, downwash, and floor lighting, for example, and save your configuration. Ditto for the galley and lav. Especially appealing to prospective customers are the customized, edge-lighted cup holders with company logos, he says. You can even adjust the look of the white light to be warm or cool. It’s “extremely easy to use,” Lockerby says. “All of these functions can be controlled right from any carry-on device…at the press of a button on a phone or from a switch in the cabin.”

PRIZM was developed as an exclusive offering, but in the last six months it has been expanded to about a dozen dealers, such as Banyan Air Service, Duncan Aviation, Constant, and West Star. Fifteen to 16 airplanes are flying with the system so far, he says, including King Airs, Citations, and Hawkers.

Elliott Technologies has made some tweaks during the slowdown. Boot time for the controller box has dropped from 30 seconds to 10 seconds and the transition between colors is smoother.

The mod is typically done along with an inspection or other interior work. The panels typically are removed and the controller box can be installed under the floor boards. Elliot’s LED strips can be up to 16 feet long, which makes installation easier and helps avoid gaps in the lighting.

Complexity varies with the size of the plane. A Gulfstream GIV, for example, can be configured with multiple, passenger-controlled lighting zones.