by David Jensen

Well, perhaps not totally so. However, one manufacturer is applying a chemistry and design that takes battery operation a step closer to a maintenance-free goal.

Well, perhaps not totally so. However, one manufacturer is applying a chemistry and design that takes battery operation a step closer to a maintenance-free goal.

Lithium-ion (Li-ion) batteries have become ubiquitous, powering everything from smart phones to electric-powered automobiles. They can be found in aircraft, too, in portable radios, electronic flight bags and the laptop computers pilots bring on board for flight planning and check lists. Li-ion batteries have been used in military aircraft for years—for engine starts, emergency power and other functions—and they have become widely employed in unmanned air vehicles. They serve as main-ship batteries in the Boeing F-18, Lockheed Martin F-35, Sikorsky CH-53K and Northrop Grumman Global Hawk, among other aircraft.

However, Li-ion batteries have yet to reach their full potential in the civil aviation arena. This is primarily because new-technology batteries require extensive effort and money to prove they meet certification requirements.

But the use of Li-ion batteries in aircraft may soon become widespread after more light is shed on their benefits. These rechargeable power units—in which lithium ions move from the negative electrode to the positive electrode during discharge and move the opposite direction during charging—represent the latest generation in the evolution of aircraft batteries. They succeed those utilizing lead-acid and nickel-cadmium (NiCad) chemistries, both more than a century old.

Improved battery technology has become more and more vital, not only to perform conventional functions such as engine starts, power stabilization and running onboard electrical systems, but also to supply an ever-growing number of systems in what many commonly call “the more electric airplane.” To give just one example of this trend, Honeywell and Safran have partnered to develop electrically controlled taxiing for commercial aircraft, to allow engine startups away from the gate thus reducing fuel consumption.

A relatively new (introduced as a product in the 1970s) and therefore emerging technology, Li-ion offers advantages over lead-acid and NiCad technologies. Newer aspects of Li-ion technology can provide greater energy density, more consistent power delivery, environmental benefits and reduced weight, among other gains. They also can reduce battery maintenance significantly, in part by simplifying and reducing the required number of battery checks. Indeed, new versions of Li-ion chemistry may some day reduce the need for dedicated battery shops at fixed-base operations (FBOs).

Bit of Controversy

A relatively new technology invariably draws controversy, however. In the field of consumer goods, a spate of incidents occurred late last year in which the Li-ion batteries on hoverboards—essentially self-balancing, powered scooters—burst into flames during recharge mode. It prompted airlines to bar stowing hoverboards on board their aircraft.

In the aviation field, two operators of the Boeing 787 Dreamliner, All Nippon Airways and Japan Airlines, made emergency landings in January 2013 because the lithium metal oxide batteries in the new-design aircraft overheated, released electrolyte vapors and created oxygen within their cases. The incidents resulted in internal thermal runaway, or accelerated heat buildup, that created fire outside the batteries’ steel cases. The National Transportation Safety Board (NTSB) cited “deficiencies in the [battery’s] design and certification processes” as the overall reason why the incidents occurred.

The 787 has two lithium metal oxide batteries onboard that provide backup power. Their malfunction invoked a three-month, fleet-wide grounding. Boeing had the battery installation redesigned, and in April 2013 the FAA gave the 787 fleet the green light to fly.

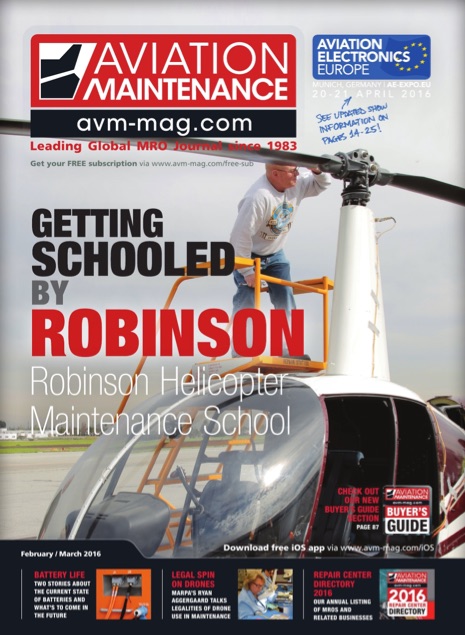

[fullwidth background_color=”” background_image=”” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ background_repeat=”no-repeat” background_position=”left top” video_url=”” video_aspect_ratio=”16:9″ video_webm=”” video_mp4=”” video_ogv=”” video_preview_image=”” overlay_color=”” overlay_opacity=”0.5″ video_mute=”yes” video_loop=”yes” fade=”no” border_size=”0px” border_color=”” border_style=”” padding_top=”20px” padding_bottom=”20px” padding_left=”0px” padding_right=”0px” hundred_percent=”no” equal_height_columns=”no” hide_on_mobile=”no” menu_anchor=”” class=”” id=””][title size=”1″ content_align=”left” style_type=”double” sep_color=”” margin_top=”” margin_bottom=”” class=”” id=””]CURRENT ISSUE[/title][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” lightbox_image=”” style_type=”bottomshadow” hover_type=”none” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”center” link=”https://www.avm-mag.com/wp-content/mag/flipbooks/AVM-2016-02-DIGITAL/index.php#Aviation_Maintenance_Magazine/page2-page3″ linktarget=”_blank” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]  [/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][/one_third][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][title size=”2″ content_align=”left” style_type=”underline” sep_color=”” margin_top=”” margin_bottom=”” class=”” id=””]IssueHighlights:[/title][checklist icon=”” iconcolor=”#81d742″ circle=”no” circlecolor=”” size=”18px” class=”” id=””][li_item icon=””]Getting schooled by Robinson[/li_item][li_item icon=””]The Care and Feeding of Batteries[/li_item][li_item icon=””]Lithium Ion Batteries[/li_item][li_item icon=””]Intelligence: News[/li_item][li_item icon=””]Intelligence: About People[/li_item][li_item icon=””]Intelligence: Aviation Electronics News[/li_item][li_item icon=””]2016 Aviation Maintenance Repair Center Directory[/li_item][li_item icon=””]NEW! Aviation Maintenance Buyer’s Guide[/li_item][/checklist][/one_third][one_third last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” lightbox_image=”” style_type=”bottomshadow” hover_type=”none” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”center” link=”http://www.avm-mag.com/wp-content/uploads/2016/01/AVM_Calendar_2016_FINAL_v10_LORES.pdf” linktarget=”_blank” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]

[/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][/one_third][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][title size=”2″ content_align=”left” style_type=”underline” sep_color=”” margin_top=”” margin_bottom=”” class=”” id=””]IssueHighlights:[/title][checklist icon=”” iconcolor=”#81d742″ circle=”no” circlecolor=”” size=”18px” class=”” id=””][li_item icon=””]Getting schooled by Robinson[/li_item][li_item icon=””]The Care and Feeding of Batteries[/li_item][li_item icon=””]Lithium Ion Batteries[/li_item][li_item icon=””]Intelligence: News[/li_item][li_item icon=””]Intelligence: About People[/li_item][li_item icon=””]Intelligence: Aviation Electronics News[/li_item][li_item icon=””]2016 Aviation Maintenance Repair Center Directory[/li_item][li_item icon=””]NEW! Aviation Maintenance Buyer’s Guide[/li_item][/checklist][/one_third][one_third last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” lightbox_image=”” style_type=”bottomshadow” hover_type=”none” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”center” link=”http://www.avm-mag.com/wp-content/uploads/2016/01/AVM_Calendar_2016_FINAL_v10_LORES.pdf” linktarget=”_blank” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]  [/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][fusion_text]NEW – the large fold out 2016 Wall planner was inserted into the Dec/Jan issue but you can also click/view above.[/fusion_text][/one_third][/fullwidth]

[/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][fusion_text]NEW – the large fold out 2016 Wall planner was inserted into the Dec/Jan issue but you can also click/view above.[/fusion_text][/one_third][/fullwidth]