[fullwidth background_color=”” background_image=”” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ background_repeat=”no-repeat” background_position=”left top” video_url=”” video_aspect_ratio=”16:9″ video_webm=”” video_mp4=”” video_ogv=”” video_preview_image=”” overlay_color=”” overlay_opacity=”0.5″ video_mute=”yes” video_loop=”yes” fade=”no” border_size=”0px” border_color=”” border_style=”” padding_top=”20″ padding_bottom=”20″ padding_left=”” padding_right=”” hundred_percent=”no” equal_height_columns=”no” hide_on_mobile=”no” menu_anchor=”” class=”” id=””][one_full last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][fusion_text]Aviation Electronics Europe, the premier global conference and exhibition for the international avionics and aviation electronics community, met in Munich, Germany on 20th & 21st April for its latest annual industry gathering.

The event delivered a highly focussed Main Conference Programme, as well as a series of Technical Workshops and Certified Training Courses as well as the largest exhibition in aviation electronics.

Following the Opening Keynote, which saw EUROCAE Secretary General Christian Schleifer, and Lufthansa’s SESAR Program manager, Sven Kutschera, deliver insightful overviews, key updates on the SESAR and NextGen programmes from Rick Heinrich of Rockwell Collins, Dung Nguyen from Boring and Thomas Maier at Airbus, enabled delegates to gain a greater understanding of the current position and future developments.

With nearly 1000 registered industry professionals over the two days, who discovered the latest issues, challenges and technologies, and listened to some of the leading international experts in relation to SESAR, NextGen programmes, as well as topics including ADS-B, Cyber Security, Satellite based solutions and Standardization and Certification.[/fusion_text][/one_full][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” gallery_id=”” lightbox_image=”” style_type=”bottomshadow” hover_type=”zoomin” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”none” link=”” linktarget=”_self” animation_type=”0″ animation_direction=”down” animation_speed=”1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]  [/imageframe][/one_third][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” gallery_id=”” lightbox_image=”” style_type=”none” hover_type=”zoomin” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”none” link=”” linktarget=”_self” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]

[/imageframe][/one_third][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” gallery_id=”” lightbox_image=”” style_type=”none” hover_type=”zoomin” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”none” link=”” linktarget=”_self” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]  [/imageframe][/one_third][one_third last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” gallery_id=”” lightbox_image=”” style_type=”none” hover_type=”zoomin” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”none” link=”” linktarget=”_self” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]

[/imageframe][/one_third][one_third last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” gallery_id=”” lightbox_image=”” style_type=”none” hover_type=”zoomin” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”none” link=”” linktarget=”_self” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]  [/imageframe][/one_third][/fullwidth]

[/imageframe][/one_third][/fullwidth]

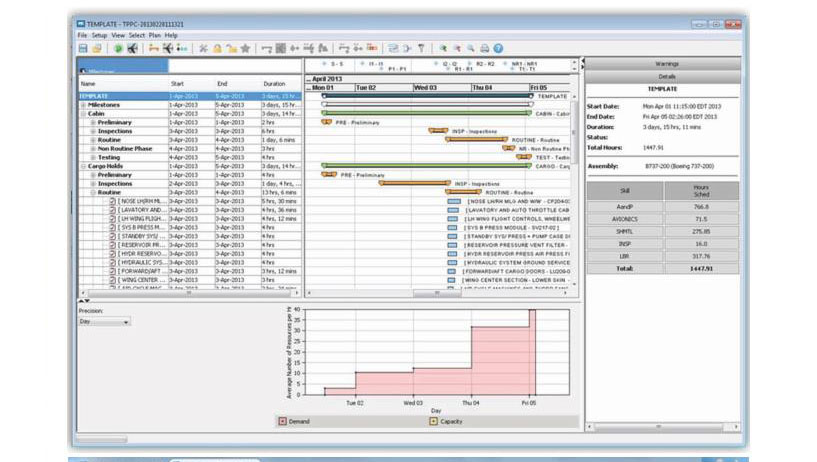

Automation is everywhere you look — in the hangar and repair shop as well as the cockpit. For the repair shops, line maintenance operations, MROs, and airline support departments that make the best use of it, computer technology gives a competitive edge in this tight-margin business. Benefits include lower costs, higher efficiencies, and greater capacity.

Automation is everywhere you look — in the hangar and repair shop as well as the cockpit. For the repair shops, line maintenance operations, MROs, and airline support departments that make the best use of it, computer technology gives a competitive edge in this tight-margin business. Benefits include lower costs, higher efficiencies, and greater capacity. Whether you are shaking up a rattle can or yielding a high-end airless spray gun, there’s a lot more to achieving a great paint finish than picking the right color.

Whether you are shaking up a rattle can or yielding a high-end airless spray gun, there’s a lot more to achieving a great paint finish than picking the right color. [/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][/one_third][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][title size=”2″ content_align=”left” style_type=”underline” sep_color=”” margin_top=”” margin_bottom=”” class=”” id=””]IssueHighlights:[/title][checklist icon=”” iconcolor=”#81d742″ circle=”no” circlecolor=”” size=”18px” class=”” id=””][li_item icon=””]Editor’s Notebook[/li_item][li_item icon=””]Intelligence: News[/li_item][li_item icon=””]Intelligence: About People[/li_item][li_item icon=””]Intelligence: Aviation Electronics News[/li_item][li_item icon=””]Setting the Standard[/li_item][li_item icon=””]Borescopes from Basic to Bodacious[/li_item][li_item icon=””]Parts, Parts, … Who has the Parts?[/li_item][li_item icon=””]Smart Assets[/li_item][/checklist][/one_third][one_third last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” gallery_id=”” lightbox_image=”” style_type=”bottomshadow” hover_type=”none” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”center” link=”http://www.avm-mag.com/wp-content/uploads/2016/01/AVM_Calendar_2016_FINAL_v10_LORES.pdf” linktarget=”_blank” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]

[/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][/one_third][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][title size=”2″ content_align=”left” style_type=”underline” sep_color=”” margin_top=”” margin_bottom=”” class=”” id=””]IssueHighlights:[/title][checklist icon=”” iconcolor=”#81d742″ circle=”no” circlecolor=”” size=”18px” class=”” id=””][li_item icon=””]Editor’s Notebook[/li_item][li_item icon=””]Intelligence: News[/li_item][li_item icon=””]Intelligence: About People[/li_item][li_item icon=””]Intelligence: Aviation Electronics News[/li_item][li_item icon=””]Setting the Standard[/li_item][li_item icon=””]Borescopes from Basic to Bodacious[/li_item][li_item icon=””]Parts, Parts, … Who has the Parts?[/li_item][li_item icon=””]Smart Assets[/li_item][/checklist][/one_third][one_third last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” gallery_id=”” lightbox_image=”” style_type=”bottomshadow” hover_type=”none” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”center” link=”http://www.avm-mag.com/wp-content/uploads/2016/01/AVM_Calendar_2016_FINAL_v10_LORES.pdf” linktarget=”_blank” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]  [/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][fusion_text]NEW – the large fold out 2016 Wall planner was inserted into the Dec/Jan issue but you can also click/view above.[/fusion_text][/one_third][/fullwidth]

[/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][fusion_text]NEW – the large fold out 2016 Wall planner was inserted into the Dec/Jan issue but you can also click/view above.[/fusion_text][/one_third][/fullwidth]

[/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][/one_third][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][title size=”2″ content_align=”left” style_type=”underline” sep_color=”” margin_top=”” margin_bottom=”” class=”” id=””]IssueHighlights:[/title][checklist icon=”” iconcolor=”#81d742″ circle=”no” circlecolor=”” size=”18px” class=”” id=””][li_item icon=””]Getting schooled by Robinson[/li_item][li_item icon=””]The Care and Feeding of Batteries[/li_item][li_item icon=””]Lithium Ion Batteries[/li_item][li_item icon=””]Intelligence: News[/li_item][li_item icon=””]Intelligence: About People[/li_item][li_item icon=””]Intelligence: Aviation Electronics News[/li_item][li_item icon=””]2016 Aviation Maintenance Repair Center Directory[/li_item][li_item icon=””]NEW! Aviation Maintenance Buyer’s Guide[/li_item][/checklist][/one_third][one_third last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” lightbox_image=”” style_type=”bottomshadow” hover_type=”none” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”center” link=”http://www.avm-mag.com/wp-content/uploads/2016/01/AVM_Calendar_2016_FINAL_v10_LORES.pdf” linktarget=”_blank” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]

[/imageframe][separator style_type=”none” top_margin=”” bottom_margin=”20″ sep_color=”” border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”” class=”” id=””][/one_third][one_third last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][title size=”2″ content_align=”left” style_type=”underline” sep_color=”” margin_top=”” margin_bottom=”” class=”” id=””]IssueHighlights:[/title][checklist icon=”” iconcolor=”#81d742″ circle=”no” circlecolor=”” size=”18px” class=”” id=””][li_item icon=””]Getting schooled by Robinson[/li_item][li_item icon=””]The Care and Feeding of Batteries[/li_item][li_item icon=””]Lithium Ion Batteries[/li_item][li_item icon=””]Intelligence: News[/li_item][li_item icon=””]Intelligence: About People[/li_item][li_item icon=””]Intelligence: Aviation Electronics News[/li_item][li_item icon=””]2016 Aviation Maintenance Repair Center Directory[/li_item][li_item icon=””]NEW! Aviation Maintenance Buyer’s Guide[/li_item][/checklist][/one_third][one_third last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][imageframe lightbox=”no” lightbox_image=”” style_type=”bottomshadow” hover_type=”none” bordercolor=”” bordersize=”0px” borderradius=”0″ stylecolor=”” align=”center” link=”http://www.avm-mag.com/wp-content/uploads/2016/01/AVM_Calendar_2016_FINAL_v10_LORES.pdf” linktarget=”_blank” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” hide_on_mobile=”no” class=”” id=””]