Even with an attendant nearby, a mechanic operating inside an aircraft wing or other enclosed space can be overtaken by noxious fumes in minutes. To improve on the safety of workers at Air Force and other defense depots, Aptima and partner, Lockheed Martin Aeronautics (LM-Aero) are devising a new Confined Space Monitoring System that draws on several R&D innovations. The new end-to-end system will provide continuous real-time monitoring of worker locations, their vital functions, and surrounding environmental conditions, improving detection and injury prevention.

Two contracts totaling $4.3 million have been awarded to Aptima to accelerate the transition of technologies developed through the Small Business Innovation Research (SBIR) program. The monitoring system was conceived in response to the Air Force Sustainment Center’s “Complex of the Future,” which aims to increase worker safety, reduce costs, and boost efficiencies across all Air Logistics Complexes (ALCs), where military aircraft are maintained and readied for service.

Boosting worker safety and efficiency

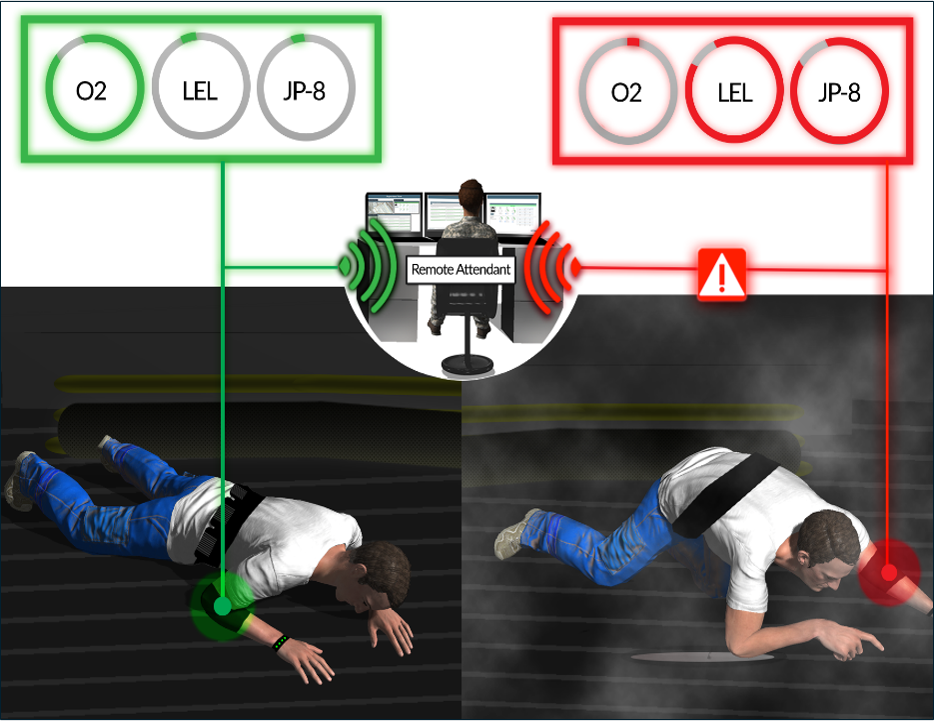

Current safety protocols require an observer to check in and communicate with a confined space worker every 15 minutes or so as they operate in small, out-of-sight areas in the presence of toxic gases, low oxygen, electrical, and other hazards.

The new system uses non-invasive sensors worn by maintenance and repair workers to transmit their physiological, environmental, and location data to a central monitoring station. Algorithms assess and classify their health and safety status by interpreting heart rate, breathing, motion, air quality, and other indicators. A single operator using the Confined Space Monitoring System can readily monitor the “green, yellow, red” health status of multiple workers simultaneously. Should the system sense or identify a problematic worker state, its built-in decision support will coordinate appropriate interventions and emergency response.

“The ‘sense, assess, augment’ capabilities of this system are a direct result of Aptima’s SBIR work with the Air Force Research Laboratory’s 711th Human Performance Wing over the past 10+ years,” said Mr. Kevin Durkee, Lead for Aptima’s Adaptive Augmentation Technologies (A2T) capability. “We recognized back then the potential to transition sensor-based technologies and big data modeling approaches from the laboratory to the field. Monitoring of confined spaces in Air Force maintenance depots is a natural and useful application of the technologies we’ve developed.”

Another innovation incorporated into the system is the use of non-GPS-reliant tracking for maintaining locational awareness of workers at all times. Whereas GPS-based signal tracking can be impeded inside hangars, metal enclosures, and confined spaces, the new monitoring system can pinpoint a worker’s position with high accuracy and position without a GPS connection, expediting assistance should they become incapacitated or injured.

The result is a solution that significantly improves worker safety while reducing the manpower costs relative to current monitoring processes.

Aptima and LM-Aero’s development of a system of networked sensors and algorithms to intelligently monitor the health and safety of workers is supported by a $2.9 million contract from the Department of Defense Rapid Innovation Fund (RIF). A companion tool to provide timely assessments using the output from the system developed under the RIF contract is being developed by Aptima, LM-Aero and the University of Toledo through an additional $1.4 million SBIR Phase II.5 contract.

Boosting workforce productivity and asset readiness

The Confined Space Monitoring System’s centralized monitoring is expected to reduce by up to 80% the number of personnel currently required as safety monitors. Whereas 50 standby observers currently monitor 50 confined space workers in a 1:1 ratio, CSMS could free up nearly 40 of those observers to perform other essential tasks at air logistic complexes, boosting asset readiness and workforce productivity.

Aptima and LM-Aero estimate a three-fold return on investment for CSMS within the first five years. The prototype system will be installed at Warner Robins Air Logistics Complex (WR-ALC), positioning it for acquisition and operational usage, followed by delivery across other Air Force weapon systems. The system also has the potential for use in any domain in which workers must perform in potentially dangerous confined spaces such as disaster relief, search and rescue, and fire and safety, as well as military Subterranean (SubT) special operations.

The DoD’s Rapid Innovation Fund is supporting the transition of several technologies Aptima has developed through the Small Business Innovation Research (SBIR) program.

Acknowledgements:

The Sense-Assess-Augment framework is used courtesy of Scott M. Galster and Erica M. Johnson (May 2013, “Sense-Assess-Augment: A taxonomy for human effectiveness,” Technical Report AFRL-RH-WP-TM-2013-0002 (Applied Neuroscience Branch, Air Force Research Laboratory).