With this issue, safety expert Jeff Guzzetti will begin a series of in-depth analyses of accidents that had maintenance as a cause. Guzzetti is the president of Guzzetti Aviation Risk Discovery (GuARD), an aviation safety consulting firm that he formed following a 35-year career with the National Transportation Safety Board (NTSB), Federal Aviation Administration (FAA) and other agencies. During his 18 years at NTSB, Guzzetti was a field investigator, “go-team” engineer and Deputy Director. He then served as an Assistant Inspector General at the Dept. of Transportation and testified before Congress regarding aviation safety audits. In 2014, Guzzetti served as the Director of FAA’s Accident Investigation Division in Washington, DC until his retirement in 2019. He is a graduate of Embry-Riddle Aeronautical University with a degree in Aeronautical Engineering and holds a commercial pilot certificate with multi-engine instrument ratings in airplanes, seaplanes and gliders.

Chalk’s Ocean Airways flight 101 was supposed to be just another milk run by the oldest continuously operating airline in the world. Founded by Arthur “Pappy” Chalk in 1919, the airline had flown celebrities like Judy Garland and Ernest Hemingway to the Bahamas in the Golden Era of Hollywood and helped search for enemy submarines during World War II. Chalk’s seaplanes were glamourous icons of South Florida living, appearing in the opening of credits of the 1980s “Miami Vice” TV show and the ending credits of movie thriller, “The Silence of the Lambs.” That is until this fateful day, a week before Christmas, December 19, 2005, when the Grumman G-73T “Turbo Mallard” seaplane lifted off with 18 paying passengers and two pilots for a scheduled flight from Miami to the Bahamas.

On that December afternoon 14 years ago, disaster struck. As the 58-year-old seaplane gently climbed toward the cloud ceiling, numerous fatigue cracks in the metal structure of the right wing grew a bit more — one last time — allowing the aerodynamic load to snap off the entire right wing.

A fireball erupted from the wing’s fuel bay and marked the airborne starting point for the fatal trajectory of the remainder of the aircraft into Miami’s shipping channel. Among the fisherman, surfers and holiday shoppers who saw the carnage, one witness snapped a photo milliseconds before the fuselage impacted the narrow channel’s shallow waters.

All 20 persons on board the seaplane were killed in a tragedy that was later determined to be caused by not only cracks in the metal, but also by larger cracks in the maintenance system.

Eighteen months later in Washington DC, the National Transportation Safety Board (NTSB) held a public Board Meeting to discuss their findings and adopt the official “probable cause” of the accident. Investigators from the NTSB “go-team” that launched to the crash site had spent months poring over the wreckage examining maintenance logs, and interviewing airline employees. They then prepared concise presentations intended to walk the NTSB’s five Board Members and a public audience through the sequence of maintenance and management failures that led to the accident – failures that serve as stark examples of how poor maintenance practices can kill.

Aging Aircraft and Metal Fatigue

Manufactured in 1947, the twin-engine Mallard had flown about 31,000 hours and logged nearly 40,000 flight cycles. It was a prime candidate for metal fatigue and other aging factors such as wear, deterioration and corrosion which occur over time in all aircraft. Metal fatigue is a weakening of metal parts of a structure due to the stress of repetitive cycling or loading. If not identified and well managed by aircraft maintenance personnel and programs, these aging processes become significant safety concerns and can, in the worst case, lead to accidents.

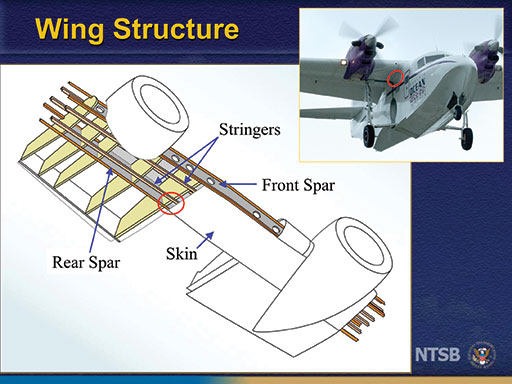

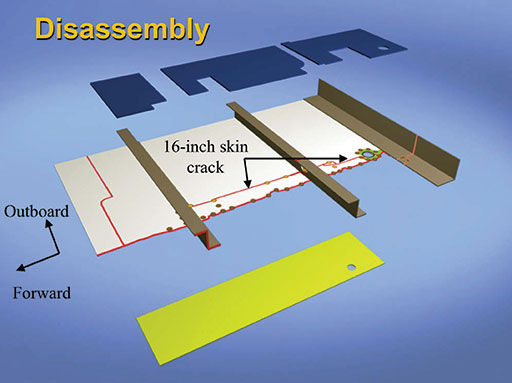

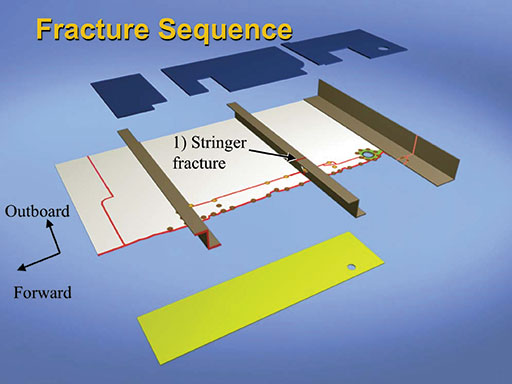

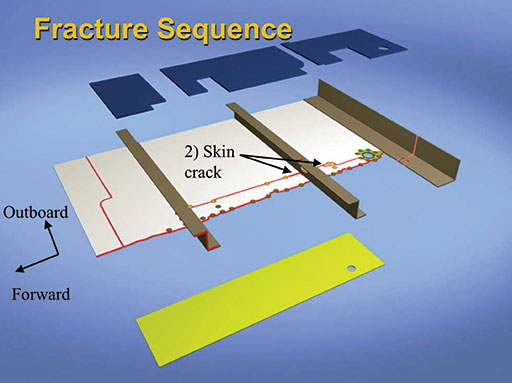

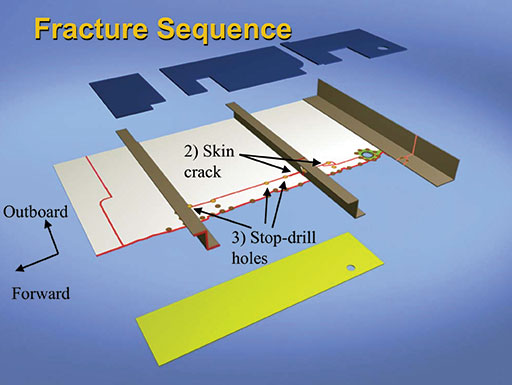

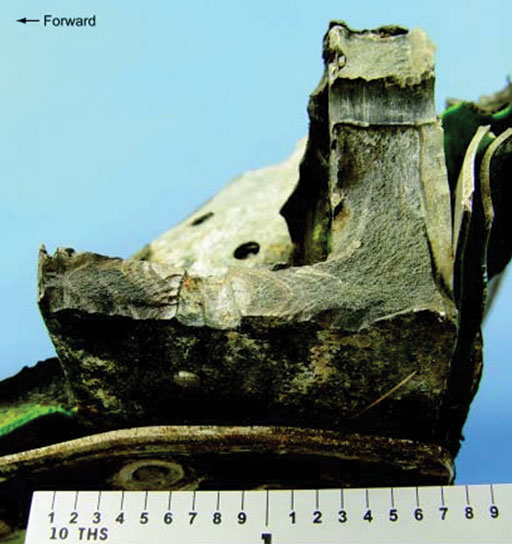

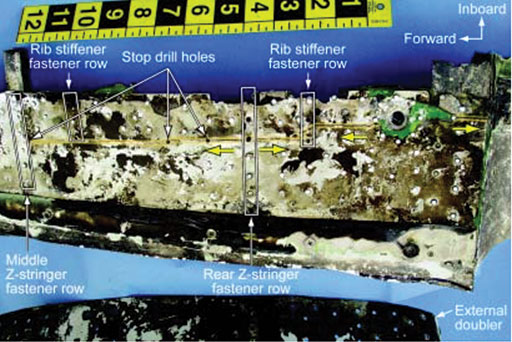

NTSB metallurgists readily determined that the right wing separated at Wing Station 34 (WS 34) due to preexisting fatigue cracks in the right wing’s rear “Z-stringer,” lower skin, and rear spar cap (see graphic 2, next page). Fatigue cracks rear their ugly heads as “beach marks” on a fractured component – marks like those made when the tide washes up on a beach and leaves parallel lines as it recedes (see graphic 2, next page). The metallurgists opined that the metal fatigue damage reduced the residual strength capability of the right-wing structure resulting in the wing’s failure during normal flight operations.

Deficient Repairs

Investigators not only laid out the facts of the Chalk’s flight 101 accident with large screen presentations, they also put on a clinic about the principals of FAA Advisory Circular AC 43.13-1B, “Acceptable Methods, Techniques, and Practices – Aircraft Repairs and Inspections.” The NTSB experts painted a vivid picture of how mechanics did not follow the structural repair methods in AC 43.13-1B in the area of the right-wing failure (see graphic 1 below). For example:

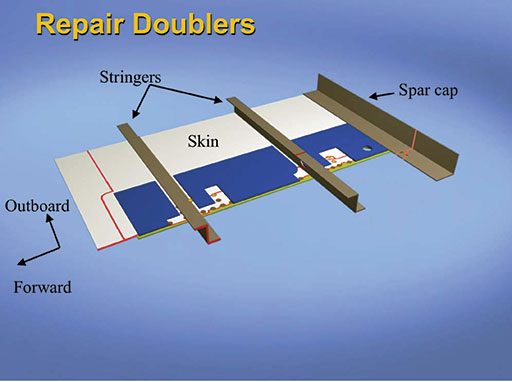

- One of the internal doublers at WS 34 partially covered the lower flange of the rear Z-stringer, suggesting the doubler was an attempt to reinforce the stringer. However, doubling only the lower flange did not restore the strength of the fractured stringer.

- Multiple-site fatigue damage was found at the inboard fastener row for the doublers at WS 34, and this damage linked up to the area of the rear Z-stringer before the wing separated, indicating that repairs in this area were not effective.

Several rivets in the inboard row of rivets for the doubler repair at WS 34 were inserted through sealant near the fuel sump drain instead of the lower skin, resulting in a failure to allow the transfer [of] the aerodynamic loads between the skin and the doublers in that area.

- Three stop-drill holes were noted in the area of the doubler repair to the lower skin at WS 34. The holes were evidence that the skin crack was detected at least three times before the doublers were applied and that the crack had extended twice from the location of a previous stop-drill hole. Continued crack growth from a stop-drill hole is indicative of an underlying structural problem that was not properly addressed in previous maintenance actions.

Sanding marks were observed at WS 34 around the rear Z-stringer fuel tank “slosh hole” and associated fracture surfaces, suggesting that the sanding was an attempt to remove cracking that had been detected in the Z-stringer. Sanding is not recommended in AC 43.13-1B. The cracking was not completely removed and continued to propagate over time.

Unresolved Fuel Leaks Indicators

The wing of the accident airplane had been weeping fuel for months in the area of the right-wing separation. Major structural components in this area – and also in other areas on the plane — had numerous pre-existing fatigue cracks. As these cracks developed over the course of years, they were manifested by fuel leaks and other repeated discrepancies. Attempts by Chalk’s mechanics to resolve these discrepancies were ineffective, literally stop-gap measures that did not correct the underlying damage to restore the load-carrying capability of the wing structure.

Losing a wing may seem like a freak occurrence, but trouble at Chalk’s was widely known. The airline’s safety culture was anemic, as were the mechanics’ attempts to seal the wing cracks. Even the FAA inspectors who oversaw the airline knew about the many shortcuts being performed, but nobody addressed the root causes. In fact, three of the six captains who flew for Chalk’s left the company in the year before the accident due to their concerns about safety.

Buried in the NTSB’s record of pilot interviews are many startling concerns expressed by the pilots who left the company. Investigators reported things like: “He left Chalk’s because of maintenance concerns. He did not have another job lined up at the time he resigned.”

Investigators also cited from a 4,000-word letter written by another captain to the Chalk’s director of operations: “I have heard numerous times, ‘We’ll just have to make up a tag for an old part back there because we don’t have any,’ the letter stated. The former captain also wrote: “I have repeatedly heard directly from the mechanics that they don’t have the ability to fix a write-up, yet it’s always signed off the next morning.”

Insufficient Quality Control and Oversight

The Chalk’s seaplane was being operated under the same Federal Aviation Administration (FAA) Part 121 rule as any other scheduled commercial air carrier in the U.S. Part 121 provides the most stringent operating requirements for aviation, yet NTSB investigators were able to document that repairs were not performed using best maintenance practices like the ones cited above, as well as a laundry list of other maintenance deficiencies such as:

- The company’s quality control program was not effective

- Repair thresholds for crack damage were not established

- Repetitive maintenance gripes on the accident airplanes and its sister ships were not sufficiently addressed and resolved

- Comprehensive inspection of the Chalk’s fleet was not performed despite widespread and well-known problems with fuel leaks in two seaplanes that continued even after major repairs.

- Major structural repairs for the accident aircraft and a sister ship were not recorded

- Flight log entries were missing

- Inspections failed to address structural damage and shoddy repair workmanship. Some stringer fractures had existed for years, and non-conforming repairs were not corrected

The Safety Board also focused on the FAA’s oversight of Chalk’s maintenance program during the public meeting. The airline was too small to have an engineering department to provide mechanics with solid technical guidance, and the aircraft manufacturer no longer provided those services. Instead, Chalk’s had individual contracts with many designated engineering representatives (DERs). The NTSB argued that this type of support did provide a solid understanding of the Chalk’s fleet. The situation was made worse by the fact that a structural repair manual was not issued for the G-73 seaplane because one was not required back when the plane was manufactured.

The Safety Board concluded that the FAA’s procedures for maintenance program oversight for commercial operators of aircraft with limited manufacturer or engineering support were “insufficient” to ensure safety, and they issued recommendations to FAA to do something about it.

“Why this happened was about a different type of failure,” said NTSB vice chairman Robert Sumwalt, who is now the NTSB Chairman. “It was a failure of Chalk’s to identify and properly repair fatigue cracks in the wing, and I think to some extent it’s the failure of the regulatory authority… to provide sufficient oversight of this operator.”

Probable Cause

The NTSB determined that the probable cause of this accident was “the in-flight failure and separation of the right wing during normal flight, which resulted from the failure of the Chalk’s Ocean Airways maintenance program to identify and properly repair fatigue cracks in the right wing,” as well as the “failure of the FAA to detect and correct deficiencies in the company’s maintenance program.”

The Chalk’s fleet was an enduring icon for aviation, but it was as high-maintenance as it was glamourous. As a result of the accident, the airline went out of business.

This investigation highlights the importance of ensuring the structural integrity of older aircraft. While the aviation industry has made significant strides in this area over the past decade, operators continue to fly aircraft beyond their original design service goals and aging aircraft will continue to be an area that bears watching.

The Chalk’s flight 101 crash is a cautionary tale that emphasizes the role that pilots, mechanics, management and FAA inspectors have in establishing a positive safety culture. We must all strive to “connect the dots” of repetitive maintenance issues in order to prevent an unairworthy aircraft from taking off.