ITT Aerospace Controls has expanded and redesigned its aircraft component line with five new valves and actuators, providing customers with market-leading solutions to control fluid handling valves used in fuel, hydraulics, water, and environmental controls systems in the aerospace and defense markets.

While Aerospace Controls’ newest components are manufactured and offered individually, they can also be assembled together for a complete electrically operated valve. The combination of these products, designed to improve aircraft operations, provides customers with cost, maintenance, and procurement logistics benefits, the company says.

“ITT Aerospace Controls developed these products based on our over 90 years of aerospace industry experience and customer feedback. This industry evolution represents a significant improvement over existing technology in the field,” said Steve Kim, vice president and general manager, ITT Aerospace Controls. “We achieved significant performance and reliability improvements by innovating the seal designs and optical electro-mechanical sensor.”

ITT Aerospace Controls’ newly expanded aircraft component line now features:

- Opto Electronic Actuator (OEA) – This actuator incorporates several new features, including optical, non-contact position sensing and a solid-state motor drive, to improve reliability in high vibration and shock environments compared to electro-mechanical micro switches. ITT’s unique technologies have two domestic patents, US7105801 and US7717397, and various associated international patents.

- Modulating Control Actuator (MCA) – While a typical shutoff valve is either completely open or closed, the MCA can drive the valve to an enhanced position between 0 and 90 degrees, restricting the flow of fluid to improve process control and system efficiency. For example, the MCA can control fluid coolant flow to regulate a system’s temperature to peak performance.

- Compact Actuator – While conventional actuators use a single switch to perform the dual functions of motor control and position indication, the Compact Actuator has an additional switch to separate them, eliminating the potential for a latent failure. Higher reliability is realized through the use of a solid-state directional control in lieu of typical electro-mechanical relays. Future development plans will include the option for optical non-contact position sensing, similar to the OEA.

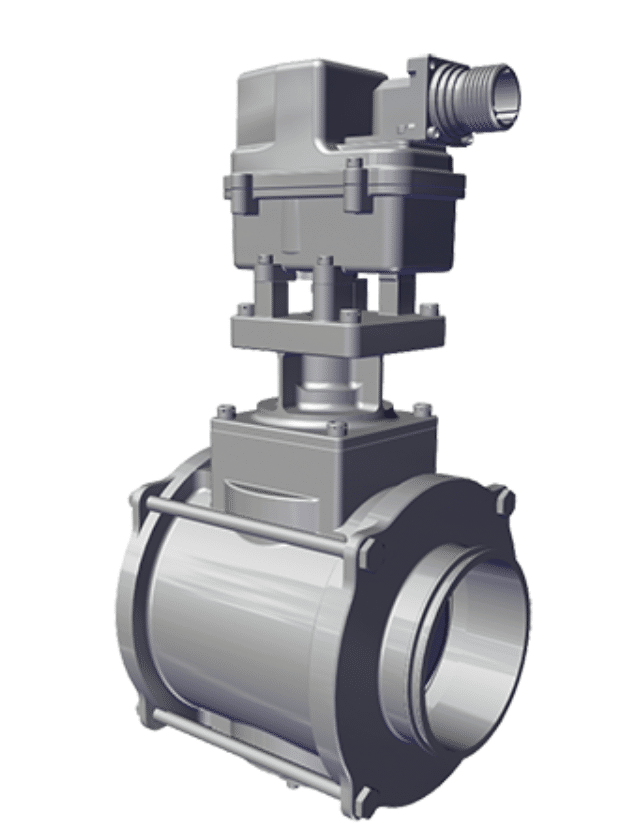

- Ridge Seal Valve (RSV) – This electric motor actuated, normally closed valve features a patent-pending design that dramatically reduces internal leakage and provides high reliability for fluid handling by controlling flow. Compared to traditional ball valves that incorporate a line contact sealing surface, our innovative Ridge Seal Valve ensures less wear and superior sealing performance. Patents are expected by the end of 2022.

- Dual Motion Shutoff Valve (DMSOV) – The dual motion valve design incorporates a sequencing drive and an eccentric shaft mechanism. This combination synchronizes the operation to linearly retract the valve disk from the seal surface and rotate the valve to open. The valve design provides superior sealing performance, maximizes seal life, and has the added benefit of reduced torque requirement at low temperature due to elimination of friction. Patents are expected by the end of 2022.