Maintenance, repair and overhaul (MRO) outfits are honing digital capabilities to capture Covid’s lessons learned just as new problems challenge their ability to prosper.

Easing now are disease-related fears and restrictions that since 2020 depressed demand for air travel and MRO services that support it. Rising is the number of people who can fly without wearing masks or proving they are free of Covid. From Albania to Zimbabwe, dozens of countries have lifted travel constraints.

That fueled flight hours, a key MRO demand driver. According to the latest MRO forecast, narrow-body aircraft on average flew 7.3 hours each day this year (through late April) and wide-bodies averaged 10.8. That’s 92 and 94 percent of 2019’s rate, respectively.

“The good news is we have a very tangible recovery under way,” said Airlines for America Chief Economist John Heimlich; the group represents leading U.S. airlines. “Covid seems to be legitimately behind us.”

Airlines for America

But headwinds abound — inflation at a 40-year high, rising interest rates, a depleted pool of skilled aviation labor and intensifying geopolitical instability. Russia’s February invasion of Ukraine jacked up tensions and inflation. “It’s really a matter of the ability of our revenue recovery to keep up with cost escalation,” Heimlich said.

In addition, MROs face high expectations to reduce their environmental impact and guard against cyber threats.

Fleet Facts

MROs have spent the last two years revamping operations to counter Covid challenges that included thousands of aircraft parked or retired, revenue streams disrupted, supply chains broken and operations being run remotely.

Many MROs’ responses involved new or expanded digital capabilities, from software supporting maintenance planning, artificial intelligence-enabled inspection techniques, and remote and collaborative inspection.

StandardAero

“A year ago, when in retrospect we correctly thought the worst of Covid was behind us, a lot of companies began preparing for the future, asking what it will look like,” said Alex Youngs, director of Sales and Marketing Business Intelligence for Airlines and Fleets at StandardAero, the large independent MRO. “People started to say, ‘Digitalization needs be part of my go-forward strategy,’ both from an airline and an MRO perspective. Covid forced a lot of companies to reassess how quickly they were going to embrace some of these new technologies.”

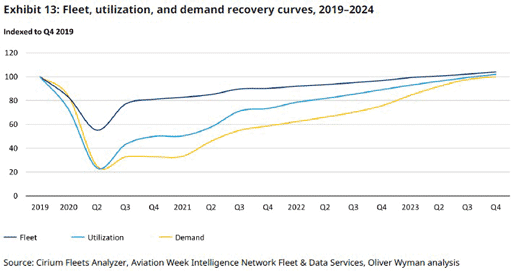

Oliver Wyman

Global consultancy Oliver Wyman’s annual outlook, “Global Fleet and MRO Market Forecast 2022-2032,” sums up what the industry faces.

“Covid took its bite,” said Brian Prentice, global lead for Operations, Manufacturing, and MRO for the firm. By 2032, global MRO spending should reach $126 billion, up from $79 billion this year. “That’s back to where it used to be before Covid.” But it would be $160 billion short of the firm’s pre-Covid, 2020 forecast.

On January 1, the report notes, the world’s airliner fleet was the size of 2017’s fleet. It is not expected to top its January 2020 apex of almost 28,000 until 2023’s first half. The fleet should grow from about 25,580 now to nearly 38,200 in a decade, with the North American fleet growing from 7,762 to about 9,600 — still one percent short of pre-Covid size.

Driving this fleet growth would be a push by manufacturers to increase production, Prentice said. By mid-decade, production should exceed 2018’s peak, with narrow-bodies growing from 58 to 64 percent of the world fleet by 2032.

As airlines pursue younger, more efficient fleets, Prentice said, more than 40 percent of the North American fleet will be retired. By 2032, 80 percent of new North American narrow-bodies will be sustainable-generation aircraft.

A fleet in transition is redefining the MRO market, the forecast says, with higher retirements of aircraft due to enter intensive maintenance. Demand should recover to pre-Covid levels by 2024, but growth after 2027 would be 2.8 percent annually.

Slower growth won’t occur everywhere, Oliver Wyman says. MRO demand for the active China-based fleet exceeded pre-pandemic levels by 2021’s end. But demand in Western Europe likely won’t recover until 2025.

Oliver Wyman also released its annual MRO survey of 150-plus senior executives. Eighty-five percent said finding workers was their biggest headache. “Already labor shortages are causing delays and flight cancellations,” Prentice said, “and that squeeze is expected to get tighter.”

Their second biggest concern is inflation.

Sustainability Soars

A new concern was sustainability imperatives. Many executives were unsure how these would affect their business, Prentice said. But almost all “recognized sustainability as a top priority moving forward” to meet reduction commitments, curb public ire over climate change, and avoid more regulation.

“The next few years are pivotal as Covid, economic forces, traveler sentiment, and government policies compel the industry to re-imagine its future,” Prentice and Oliver Wyman Senior VP/General Manager Anthony DiNota wrote in the forecast.

Current challenges may overcome the reluctance some aircraft operators and MROs feel to move on from paper-based systems and clunky, in-house electronic solutions based on Microsoft Excel and Access, according to numerous executives.

“I think we are on the cusp of airlines now saying of digital capabilities, ‘This should be general practice,’ rather than, ‘Convince us to do this,’ said StandardAero’s Youngs.

Today’s predicament may spur MROs to re-think Lean philosophy and practices that have underpinned industrial operations for decades.

Supply Chain Sputters

“There’s tremendous supply chain pressure,” said Matt Medley, Aerospace & Defense Manufacturing industry director at IFS, which develops and delivers enterprise software to maintenance operations worldwide. “There are chip shortages. Oil is hard to come by. Shipping is a nightmare. The traditional Lean philosophy of not carrying any inventory is not always the best when you don’t have the most stable supply chain.”

Southwest Airlines

Southwest Airlines is among those digitally transforming MRO operations and moving away from paper. It has deployed IFS solutions as the enterprise maintenance management standard to help optimize aircraft reliability and availability. In addition, the transformation is improving compliance “by providing real-time validation at the point of maintenance,” said Landon Nitschke, Southwest Airlines senior vice president, Technical Operations.

The IFS product is live across Southwest’s fleet of almost 730 aircraft. It provides Southwest maintenance with information to streamline configuration control and compliance management processes and helps drive efficiencies and automation of processes enabled with a mobile user experience.

“IFS gives us the peace of mind and control we need to not only maximize the airtime of our fleet but deliver” on-time flights and a great travel experience for customers, Nitschke said. He called the change “the largest single MRO system migration in the history of our industry.”

Southwest joins IFS airline customers that include Air France-KLM Group, China Airlines, and Qantas.

Medley and others said good information technology is among the best ways to extract efficiency from MRO operations while adjusting to Lean’s newly emphasized shortcomings.

IFS

“There’s been more and more cost pressure on airlines” and by extension MROs, said Elliot Margul, maintenance planning software company Aerostrat’s co-founder and CEO. “The future for them is to continue to run as lean as possible. One of the best ways to do that is IT tools.”

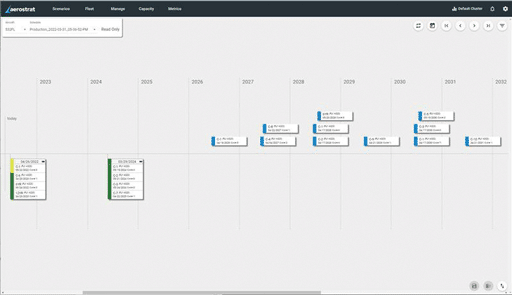

Aerostrat

Margul started Seattle-based Aerostrat with co-founders Cody Morris and Frankie Angai in 2015 after working in heavy maintenance planning and Maintenance & Engineering finance for Alaska Airlines. He found the tools available insufficient for planning maintenance tasks. They did not provide enough functionality to properly forecast and budget an aircraft’s visits years into the future. A proper plan needed to take in details, time requirements, and costs that can vary significantly airframe to airframe due to individual characteristics (such as corrosion tendencies and past repairs). “If an airline has an aircraft program that’s in C1 through C8 inspections, each aircraft has different lower-level tasks,” Margul said. “One C1 might take 20 days, one might take 27 days.”

Aerros is a secure, Cloud-based planning tool that helps customers manage such complexities. It enables detailed planning of individual tasks over the aircraft’s entire life all while maintaining a database of past work done. Aerros is designed to help manage factors such as timing and task requirements of airworthiness directives, service bulletins, engineering change orders, access overlaps, as well as labor staffing and skill requirements of future tasks.

A key benefit is Aerros’ ability to help maintenance planners understand consequences of decisions made today. “When you’re inducting an aircraft in a couple of weeks, all the decisions you’re making today affect you down the road,” Margul said. “If I decide to push tasks out because of budgetary reasons, how does that affect me a year, four years from now?”

Aerostrat is adding collaboration tools to support working remotely or with people in different locations. It has added a commenting section, and is working on integrating Aerros with Microsoft Teams. “Our priority is collaboration,” Margul said. “That’s becoming the new normal.”

Aerostrat’s customers include Alaska and sister carrier Horizon Air, FedEx Express and JetBlue.

Tech = Efficiencies

“MROs are very aware of digitization’s benefits,” said Adam Frost, product manager at OASES. “Most have ambitious targets to get it done.” He, Margul, and others said the challenge for IT providers is to meet MROs’ need with minimal disruption. “We have an opportunity to make huge improvements to efficiencies with fully digital processes.”

As customers worked at reduced capacity during the pandemic, OASES accelerated development of its use of the Cloud, implementing it for 20 new and migrated customers. It is preparing to launch a Maintenance Control feature focused on short-term planning that will “provide a clear view of the current maintenance situation, allowing our users to react appropriately to defects and scheduling changes,” Frost said.

OASES this year signed contracts with Estonia’s Skystream Airlines, start-up AirConnect of Romania, and Bulgaria’s Holiday Europe.

Numerous MROs and vendors seek to analyze maintenance data through artificial intelligence. Drones are one vehicle for doing that. Among those working on using drones to speed and supplement visual airframe inspections are AAR Corp., Korean Air, and LATAM.

OASES

Lufthansa Technik recently concluded a three-year project to explore using AI-enabled drones in base maintenance. Base mechanics must examine an aircraft’s outer skin in a crouched or crawling position, secured by harnesses to stay safe at great heights. “What if this process could be performed by inspection drones that eliminate poor ergonomics and ensure job safety and digital data output?” said Jan-Christopher Knufinke, the MRO’s Lean innovation manager.

Researchers set out to verify whether visual inspections for damage or irregularities could be optimized with an autonomous drone flying about 3.3 feet (one meter) from an airliner. Tests showed that a drone with automatic collision-avoidance/obstacle detection and an HD camera could capture high-resolution images of damage as small as 0.2 inch (5 mm) square.

Lufthansa Technik

“Implementation cannot be accomplished overnight,” Knufinke said. Infrastructure adjustments must be made, including 3D imaging of hangar infrastructure, aircraft and ground support equipment, to enable the drone to fly safely inside. Legal requirements must be addressed. “The next step will be to identify further use cases.”

Connected Aircraft Will Transform MRO

Others are using advanced systems to streamline inspections.

Safran Landing Systems and ATR have developed a landing gear diagnostics service using state-of-the-art data analysis to optimize the regional turboprop manufacturer’s response times after hard landings. Smart Lander draws on hundreds of thousands of hard-landing simulations to recommend maintenance actions to operators based on a landing’s hardness and the landing gear load level sustained. The process takes less than an hour.

“Our former process could take up to 10 to 20 working days,” said ATR Customer Support and Services Senior Vice-President David Brigante, and required analyses by ATR and Safran before the aircraft could return to service.

ATR

In March, Structural Monitoring Systems won FAA supplemental type certificate (STC) approval for a system that allows expedited structural crack inspections. It has been working with Delta Airlines to prove out its Comparative Vacuum Monitor (CVM) sensor technology. The test case was crack inspections around the Gogo Wi-Fi antenna atop a Boeing 737-800.

CVM uses vacuum and differential pressures to detect a skin crack surface by cycling air through a sensor and measuring whether outflow matches or exceeds inflow. Dave Thompson, Delta TechOps vice president for engineering, quality and safety, said the CVM system can be installed within a day and allows mechanics “to do this inspection in an hour, compared to a full day and a hangar visit.”

Delta TechOps

Digital capabilities will benefit from more communications-capable airliners entering service. Oliver Wyman says new-generation aircraft of the 2010s made up two percent of the world fleet in 2019. By 2032, they should be 51 percent of the fleet.

Inmarsat Aviation

“Connected aircraft will digitally transform the way airlines operate.” Inmarsat Aviation’s senior vice president of technology, Kurt Weidemeyer says. And MROs, too.