Stottler Henke Associates was awarded a contract with the U.S. Navy to customize and demonstrate a critical chain and critical path scheduling capability for surface ship maintenance operations. Stottler Henke’s solution is based on its Aurora intelligent planning and scheduling system, combined with built-in Critical Chain Project Management (CCPM) capabilities.

During the project, a series of demonstrations and Government tests will verify the system’s ability to solve large, resource-constrained scheduling problems, generate numerous reports and displays to provide an integrated picture of the Navy’s surface ship maintenance demands, support tens of thousands of users, and provide system administration tools. If the evaluation is successful, the Navy is expected to contract Stottler Henke to develop and deploy a customized, operational version of the system at naval shipyards, regional maintenance centers, and ship facilities.

Navy ship maintenance is extremely labor and resource intensive, and ship maintenance schedules must satisfy complex constraints. For example, many maintenance operations require different combinations of limited resources such as maintenance shops, equipment, and maintenance teams with specific skills and certifications. Large parts are removed from the ship and transported to specialized maintenance shops where they are reconditioned or repaired. Other work is performed on board in small spaces, so spatial reasoning is needed to schedule those tasks.

The US Navy has successfully used the Critical Chain Project Management (CCPM) methodology to manage other operations efficiently, so they desire a ship maintenance scheduling software system that supports CCPM. The Critical Chain method consolidates per-task safety margins into a smaller number of aggregate safety margins. By allocating safety times strategically, organizations achieve higher throughput. Also, CCPM provides organizations with greater visibility into how their projects are performing, and it provides global metrics to guide and motivate all parties to do what is best for the entire organization. For this project, Stottler Henke is teaming with Main Sail who contributes expertise in Critical Chain Project Management and Theory of Constraints.

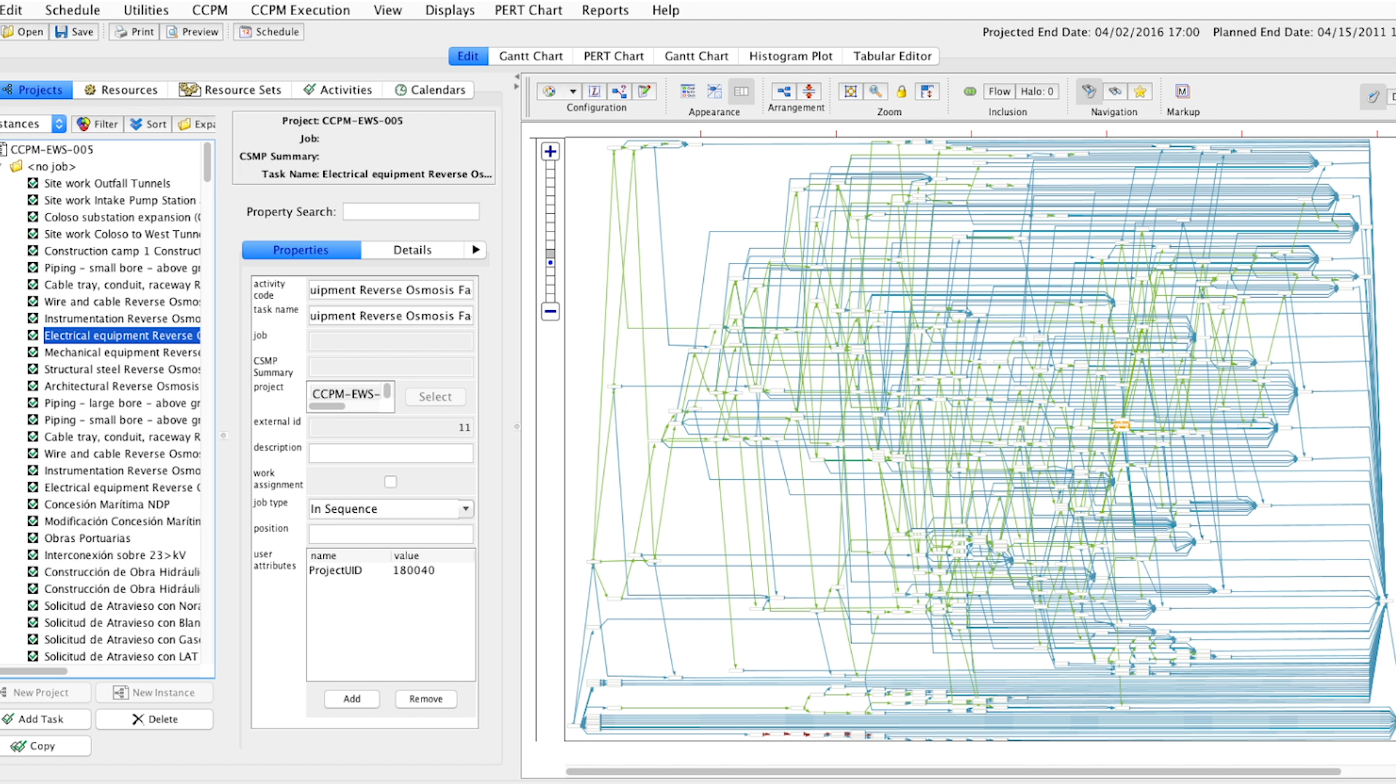

Like complex operations at many organizations, management of Navy ship maintenance requires resource-constrained scheduling of tens of thousands of activities, which is beyond the ability of ordinary CCPM software. Stottler Henke’s solution for the Navy is based on Aurora-CCPM which combines Stottler Henke’s Aurora intelligent planning and scheduling system (www.stottlerhenke.com/products/aurora) with the added power and flexibility of multi-project Critical Chain Project Management.

Aurora is the world’s leading planning and scheduling system that uses artificial intelligence to generate efficient solutions to complex, highly constrained scheduling problems. Most other systems use simple rules to schedule activities and assign resources to carry them out. Often, these schedules and resource assignments are far from optimal. Aurora outperforms conventional software because it uses artificial intelligence technologies to encode and apply extensive scheduling knowledge.

“We are delighted that the US Navy is evaluating Aurora software for managing their extensive ship maintenance operations,” says Richard Stottler, president, Stottler Henke. “Aurora’s artificial intelligence scheduling technology will improve the Navy’s readiness, save taxpayer dollars, and enable superior operations management, as already seen by the US Air Force, aircraft manufacturers, and many industries,” continues Stottler.

Aurora scheduling software was originally developed to help NASA tackle difficult, mission-critical scheduling problems with complex constraints by incorporating the judgment and experience of expert human schedulers. NASA used Aurora at Kennedy Space Center to schedule International Space Station payload and Shuttle processing activities. The Boeing Company uses Aurora to help them manage aspects of building the Boeing 787 Dreamliner™ commercial airliner. Other Aurora software users include Pfizer, Mitsubishi Heavy Industries, Korea Aerospace Industries, Massachusetts General Hospital, Bombardier Learjet, Alaska Airlines, the US Air Force, and the US Navy. Aurora was featured in NASA’s Hallmarks of Success video series which showcases successful spin-off technologies.