Kriya Shortt is the senior vice president of Global Customer Support for Textron Aviation. Last month at the NBAA convention in Las Vegas, Nev., Aviation Maintenance editor-in-chief, Joy Finnegan had the opportunity to sit down with her and discuss the challenges and opportunities of leading the global support effort for Textron Aviation, which now encompasses the Cessna, Beechcraft and Hawker product lines and more than 3000 employees spanning the globe. It can’t be an easy task, but Shortt and her team of service and support professionals make it look that way. Here is that discussion.

AVM: Textron has put together three diverse companies: Beechcraft, Cessna and Hawker. How has that transition gone over the course of the past few years?

Shortt: We just celebrated five years together as one company. It is amazing how quickly the time has gone. I am proud of how we have been able to preserve the brands’ heritage while identifying with our current customer base. The transition has been a success, particularly for our customers in terms of the level of support we can offer them. Many of our customers cross between the product lines. They might have learned to fly in a Cessna then moved into a King Air, and now they’re in a Citation. So, it’s been fun to see the points of connectivity across the customer base.

AVM: What about blending the workforce of those three brands? Was that difficult?

Shortt: We brought together three companies that, although similar, had nuanced differences, and we took the best practices from each brand, bringing them together to form today’s Textron Aviation. Our combined heritage has propelled us into the future. The Longitude, having a blended engineering team, has been an incredible success. However, there are also challenges associated with blending a workforce, particularly for us in the service industry. Brad Thress was my predecessor and he spent the first two and a half years of integration working diligently to make sure that our team had the abilities across our 145s to work on the products we serve.

AVM: What about the existing workforce?

Shortt: We’ve only added to it. We are continuing to invest in our skilled workforce by giving them the opportunity to go to King Air school or Hawker school, for example, if they have prior experience working at a Citation Service Center, to build on their capabilities and learning.

AVM: Can you give an example of a best practice you’ve implemented across the board. A situation where you looked at the way the two companies each did it and saw that Cessna did it one way and Hawker Beechcraft did it another way and then you chose one or the other?

Shortt: One that’s relevant in our support organization would be around the model communiques that Beechcraft used to talk to customers. Cessna traditionally communicated technical issues through service bulletins. Beech’s model was, ‘let’s put together a model communique and talk about something that might be going on in the fleet and not wait for a technical service bulletin to be released,’ while still giving information out to the fleet. We’ve adopted Beech’s method, implementing model communiques across the Citation fleet, the Caravans and the Beechcraft product lines. It is a great way to keep our customer base informed.

AVM: Let’s talk about the super diverse fleet that you have to support and the challenges involved with that.

Shortt: First, we think it is the ultimate blessing and privilege to serve our customer base. We have 18 service centers globally and a fleet that is constantly moving between them, which keeps us on our toes. It means we have to have the ability to put our hands on information as quickly as possible, even if it’s a product that we don’t see as frequently, so that we can have a positive impact on our customer. Our approach allows us to service the aircraft correctly the first time, which is something we’re known for. But it also enables us to solve problems quickly and get the aircraft back in the air. In today’s environment, operational availability is the true metric by which most customers measure how they utilize the aircraft.

AVM: How does Textron Aviation improve operational availability across the board?

Shortt: Our team has a direct hand in any new models that are going through engineering design certification tests. We’re embedded with those engineering teams from day one, looking at how we can make their maintenance experience the very best it can be. Our team has the expertise to advise the engineering team of the impact their plans will have on us when the aircraft is delivered to the customer. From a maintenance perspective, equally, we are able to take into account all of our past experiences to achieve some of the best maintenance intervals in the industry. The other ways we improve our operational availability are through the investment that we have, not only in our physical footprint of service centers, but the augmentation of our mobile service vehicles. We have the largest mobile service fleet in the industry – between 70 and 80 vehicles.

AVM: Say more about your mobile technical capabilities.

Shortt: We dispatch go-teams made up of talented technicians to our customers. My counterpart, Brad Thress, who runs parts and distribution, has an intentional effort underway to understand what parts we need to stock in our outlying service centers to ensure that we can meet both scheduled maintenance needs as well as AOG needs. We also invest in continuing to grow the stock rooms and floor space to increase the SKUs we can carry around the world.

AVM: Tell us about an important process or product that you personally have implemented and what were the results of that?

Shortt: Due to the 20 years I have spent in sales and marketing, I am highly focused on the front end of the business. We have a great team that delivers technically adept, skilled work. We focus on the customer experience, understanding that our customers are people and, just like you and me, they emote, they have needs and they have demands on their schedules. Approaching customers solely from a technical standpoint doesn’t always resonate. They need to feel heard and valued. I want that to be their experience when interacting with Textron Aviation

AVM: Is there training within the company that gives guidance about how to do that?

Shortt: There is. I bring my leadership team together every quarter to craft training for our customer-facing roles. It’s a twofold benefit: from a process perspective, it benefits our customers, but it also adds value to our workforce. We help the team develop both processes and professional development skills as they continue to evolve in their careers.

AVM: What technologies of the future do you see impacting service and support?

Shortt: I’m passionate about technology and its ability to create efficiencies if used effectively. Earlier this year, we launched our maintenance data hub. Historically, we had many of our customers use Cesscom from the Cessna side and Camp from the Beechcraft side. But customers want choices. So, we’ve created an environment now where we can accept data from Camp, Sierra Trax, Traxall and Flight Docs. Now, our team can enter their maintenance transaction records (MTRs) directly from our iMRO system and they flow to those systems. More importantly, being able to have multiple data feeds gives us better visibility into the fleet, which means that we can understand what removals and installations look like on a given part, allowing us to drive better reliability into the fleet for our customers. The more robust our data feeds become, the more information we have. I’d like to think we can trend predictive capabilities in our segment of the industry as well – I’m really excited by this concept. I like the idea of drones for incoming maintenance inspections, as airlines are doing. When I take my car to the dealer, they give me a video feed of what they’re doing, so why wouldn’t we have the same expectation in our industry?

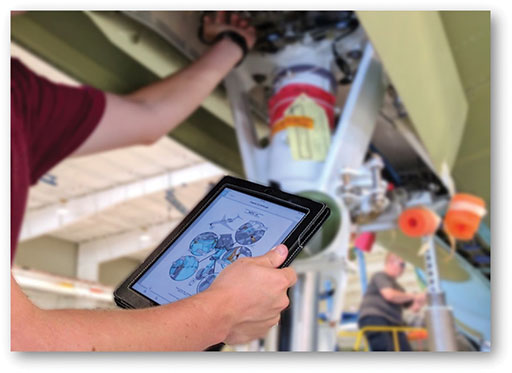

AVM: Tell our readers a bit about your new 3D Tech Pubs.

Shortt: We are hands-on in the way that we work, but that doesn’t mean we can’t leverage technology to appeal to tomorrow’s workforce. We can show our teams how we use technology smartly to help them bridge the gap between our hands-on environment and the environment that they grew up in. My kids grew up gaming, so they’re adept at using digital technology in other aspects of their lives. We are integrating more new technologies into our work, particularly through 3D Tech Pubs, the first of its kind in the industry. The way that we design and engineer aircraft now using our ENOVIA platform allows us to take that and bring it into the Tech Pubs world. For a technician who is looking at doing a job, whether they’ve done it, they’ve never done it before, or maybe they did it several months ago, they can watch a virtual step-by-step demonstration of how that process is going to play out in real-time. It also makes them faster when they perform the task on the aircraft in real life. The wiring diagram traces through to the pin-level, and in an environment where our aircraft are all fitted with more electronics, tracing wires is a skill that is going to be significantly differentiated when aided by technology.

AVM: Textron Aviation is a big organization. You have facilities all over the world. How do you implement change?

Shortt: Yes – we have 3,100 people on our team, spanning globally. I really believe the idea of one team working together is critical. I spend a lot of time listening to the team. Over the past year, I have held more than 100 roundtables globally to listen to the opinions of our technicians, avionics techs, CSRs and leadership and understand the challenges they’re facing. My aim is to champion our workforce and make their lives easier so that they can more effectively help our customers.

AVM: Give me an example of a time that you visited a facility outside of Wichita and you learned something that you wouldn’t have otherwise learned.

Shortt: I learn something every single time I visit a facility! One of the things I learned last year as I started implementing these roundtables was that our team has a passion and a desire for more training. After hearing this from more than one site, I flagged the demand for more training to the operation side of my business. We began to think about how to create a training area that would be complementary to what we do on a broader company basis and meet the needs of our team. These conversations started in December of last year and by May of this year, we had a team in place to focus on professional development and customer care training. I am passionate about encouraging those joining the company, whether they are a brand-new A&P or coming from another area in the industry, to immerse themselves and be successful from day one, because without skilled, talented technicians on our team, we can’t serve our customers.

AVM: What are your thoughts about the shortage of mechanics? Is there a shortage of skilled technicians?

Shortt: : I believe the shortage will become more and more apparent in the future, but currently, the numbers show that our skilled workforce is roughly eight years more mature than the rest of the North American workforce. We have good talent across our company, and I have had the privilege of celebrating a number of 40-year technician anniversaries this year. We are grateful for our committed team members, but we also understand that we need to continue to invest outside of the company to ensure the robustness of our manufacturing environment across the U.S., and ensure we have the skilled workforce to deliver maintenance to our customers. We recognize the importance of reaching tomorrow’s workforce while they’re still in school to encourage young people to consider careers in our industry. Our HR team, along with some key experts, created an Aviation Pathway curriculum that kicked off in August of last year. Young adults who take part, starting in the ninth grade, can graduate high school with a diploma and technical certificate, creating the potential for immediate employment within the aviation industry. For some students who perhaps don’t want to take a four-year degree and haven’t decided on their career path, the Aviation Pathway is a great option. At Textron Aviation, we’re creating a way for them to be successful as young adults, as a contributing workforce. Then, as they mature and find their passion beyond the Aviation Pathway, they could work and earn a four-year degree through our tuition aid reimbursement program. Programs such as this are instrumental in developing a workforce. We recognize that we also need to reach the educators as well, so we have developed an external program where we bring school teachers onto our campus in the summer months to give them experience and exposure to our industry so that they can promote it to middle and elementary school students.

AVM: What about outside of Wichita – are there similar programs?

Shortt: We work diligently to craft relationships with tech schools near our outlying facilities. We have apprentice programs at a number of our sites, like Hallmark University in San Antonio. We bring in students who are going through their A&P program to work at our San Antonio site. It is valuable to us that the students at Hallmark University are not only Texas-based but from different regions. This means they are mobile and keen to move into other areas to gain more experience. We have these programs at several other locations. We also work with Civil Air Patrol, which further increases our exposure in a different area. As we also partner with the industry, I have been discussing the topic with [NBAA President] Ed Bolen. We have to join together as an industry to promote the trades as a viable and robust career path.