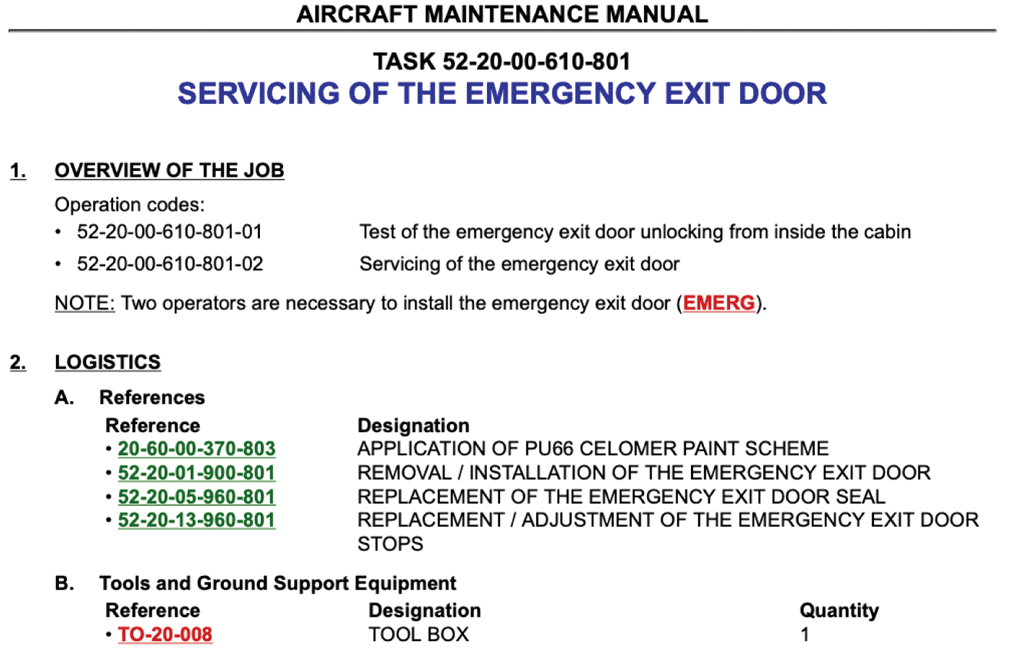

Ah, technical documentation: The necessary bane of an MRO’s life. Anyone who services aircraft needs access to the latest and most complete information about their systems, structures, limitations, and other pieces of information vital to keep them flying safely.

In the old days, having access to such technical information required maintaining massive libraries of books and other paper-based documentation. The difficulties of managing and accessing this data in a timely manner was only made worse by having to revise it whenever updates became available.

Corridor Aviation Software

“Depending on the complexity of a service center and the variety of aircraft that they maintain, a paper tech docs library can be extremely challenging and costly to manage and keep up to date — not to mention the storage implications,” said Chris Kubinski. He is vice president of Corridor Aviation Software, a member of the CAMP Systems family of aviation ERP software and services companies. “With frequent manual updates, new AD/SBs from the OEMs, and the paper tech docs being shared across the service center, there is considerable potential for failed revision control, thereby opening the door for maintenance to be performed to outdated standards or via incorrect procedures.”

The Benefits of Digitalization

Fortunately, companies such as Ambry Hill Technologies, Corridor Aviation Software, Component Control, Tdata, and Zook Aviation all offer products/services that enable a digitization of aviation technical information. And MROs large and small are eager to adopt this technology, according to Eric Schech, Ambry Hill Technologies’ product brand manager.

Ambry Hill Technologies

“The complexity and size of OEM manuals has never stopped a determined MRO operation from moving full steam ahead on anything,” he observed. “MRO operations tend to be incredibly forward-thinking and willing to innovate when the time is right.”

Of course, being able to compile, store, and access aviation technical information into a digital format does provide a host of benefits to the aviation maintenance industry.

Component Control

For instance, “Digital or cloud-based technical documentation offers the accuracy of being connected directly to the OEMs’ standards and the efficiency of being kept up to date almost instantly,” said Kubinski. “Additionally, digital technical documentation enables the entire maintenance operation to have access to the most accurate and current technical information as dictated by the OEMs. It’s quicker, more convenient, more accurate, and ultimately improves safety and performance while reducing downtime potentially caused by rework.”

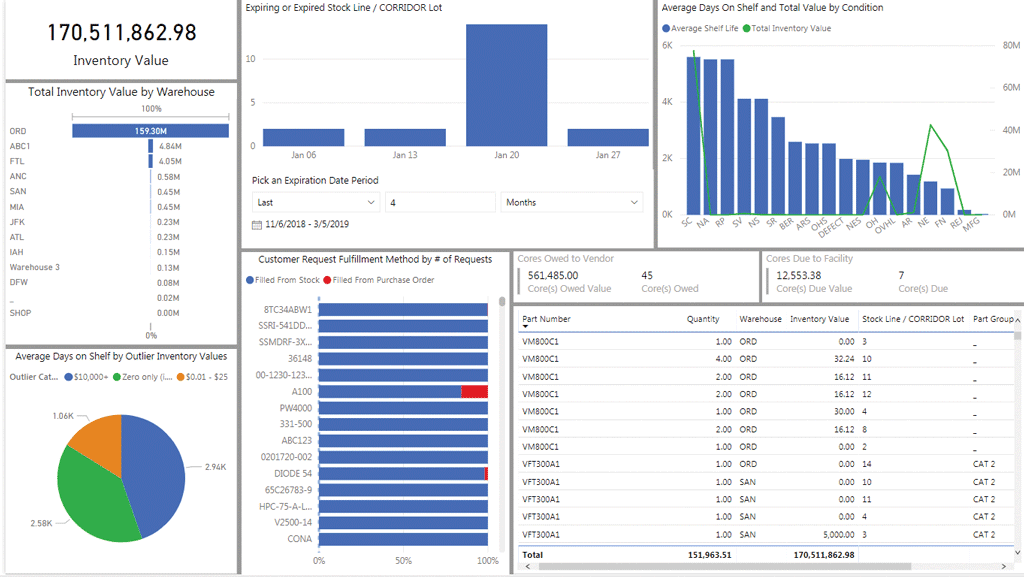

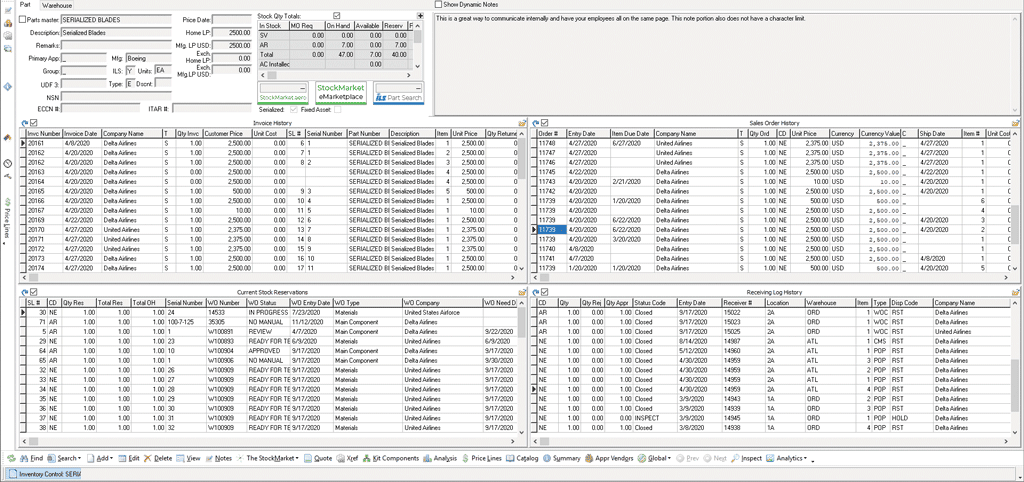

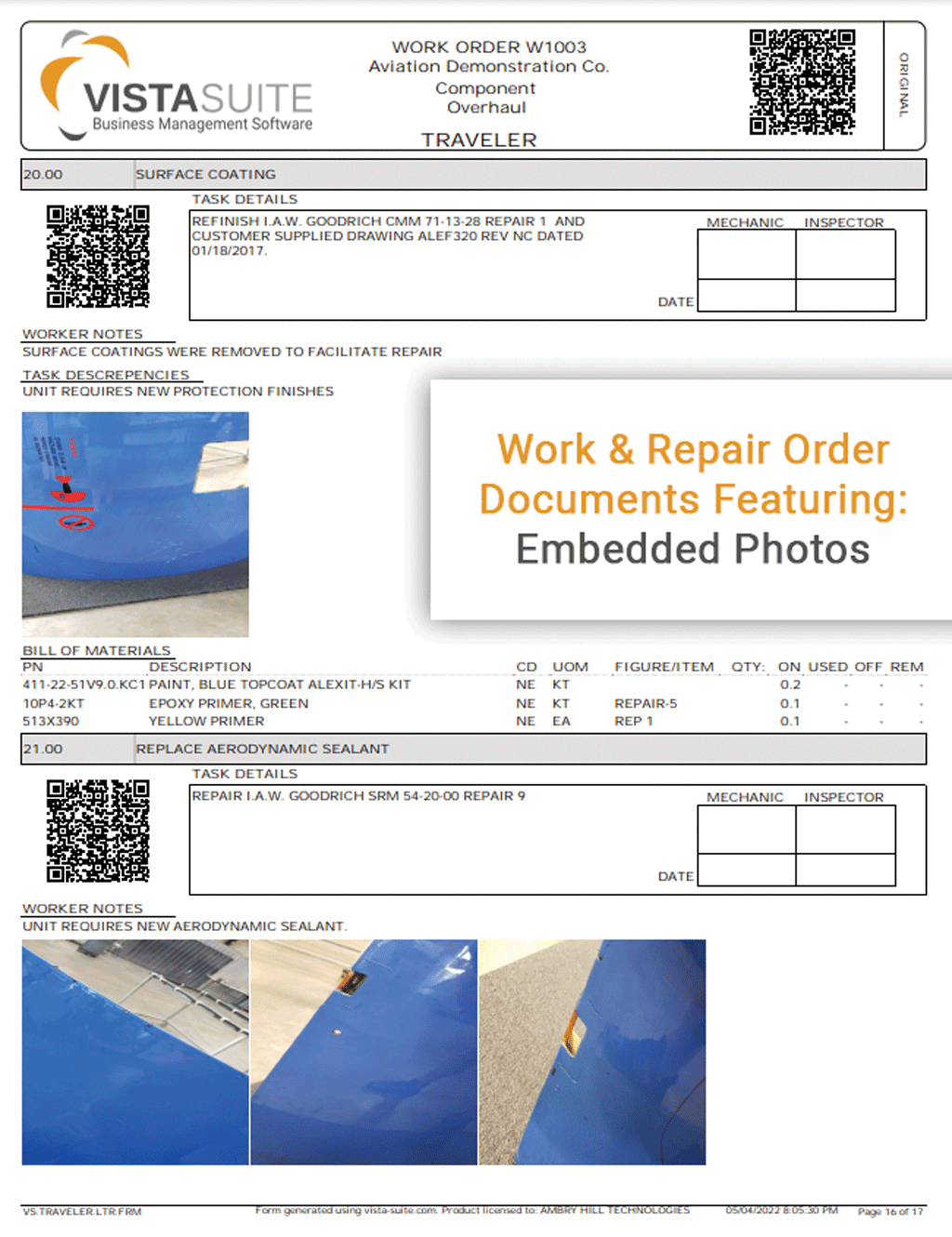

These days, the digitization of technical documentation has become an end-to-end requirement for document control, traceability, compliance, and efficiency, said Daniel Tautges, senior vice president of Component Control. Component Control is a CAMP company and their sister company is Continuum (Corridor), also owned by CAMP. “The digitization process begins at receiving parts or repairs, and includes taking a digital picture of the part, scanning the associated paperwork (i.e. 8130) and logging images directly to the stock line,” he explained. “Repair documentation for work orders associated with MRO are imaged and cataloged as well, including the digital or paper instructions that accompany the work performed to guarantee compliance with FAA/EASA requirements. Contracts, purchase orders, warranties, sales orders, and shipping documentation are also being digitized to ensure that the entire company history is being maintained within its ERP system.”

That’s not all: Storing aviation technical information digitally makes it far more searchable and accessible in many more circumstances than is possible with paper-based documentation.

Tdata

In the first instance, “State of the art database technology and metadata are used on the back end to allow for accurate search results,” said Tdata’s CEO James Thomas. “Buttons, bookmarks and links to related documents can make a huge difference in the amount of time it takes to connect the user to relevant information. Expert notes are also added to our products to eliminate if any confusion exists in the original documents. Using mobile devices only multiplies the time savings for the user.

Control image.

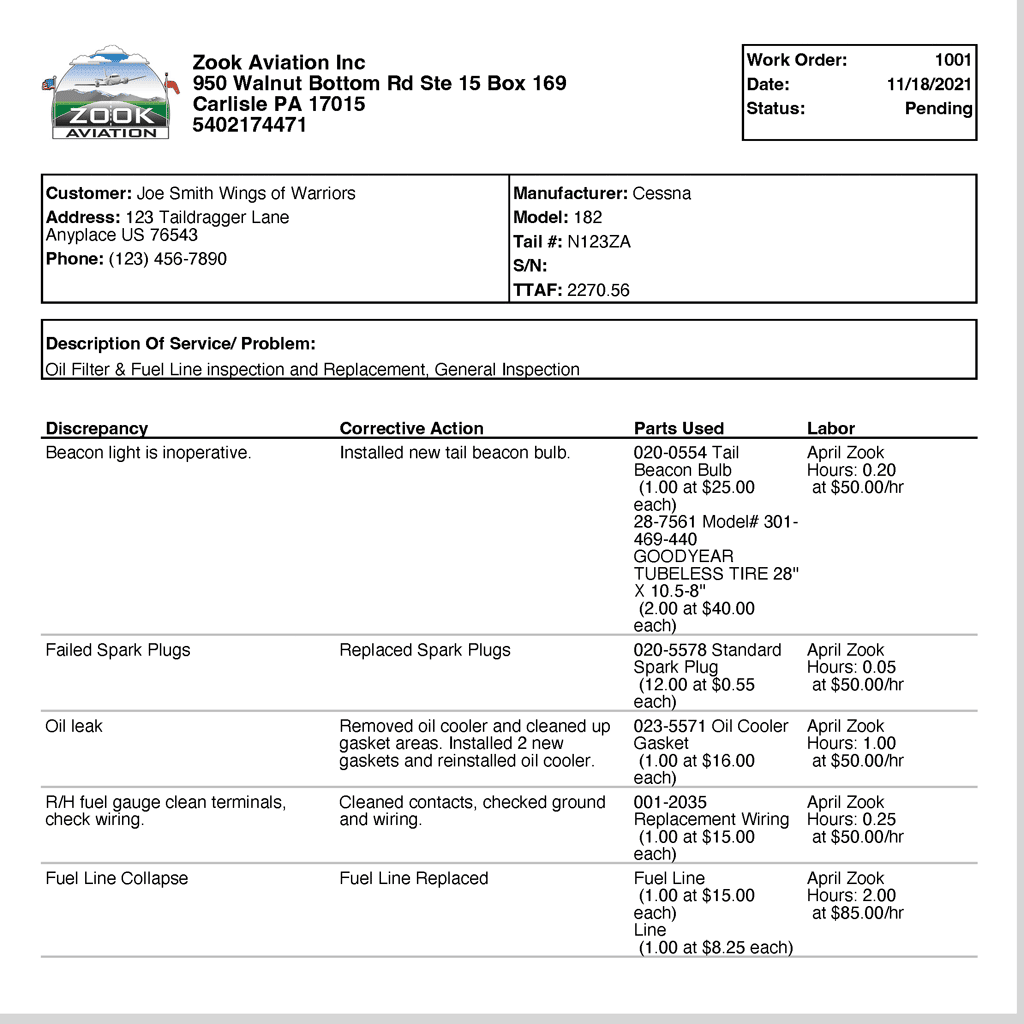

In the second instance, “digital documentation can be accessed using PC tablets, iPads, Android phones and iPhones, all making it possible to make documentation notes easier,” said Matthew Davison, account manager at Zook Aviation.

Zook Aviation

In today’s highly mobile world, where people need to access aviation technical information at any time and in any place, such ease of use is a necessity. Storing technical data electronically, rather than on a bookshelf, removes any limits on the quantity of data being retained. “Our cloud-based VistaSuite software has unlimited storage for photo, video and documents, with the ability to correlate the media to certain transactions, stock lines, and work orders, Schech said. “This approach means that every resource is accessible at all times online and through the VistaSuite mobile app.”

Digitalized technical documents can also be integrated into an MRO’s ERP management system. This allows these documents to play an active, positive role in streamlining business processes.

A case in point: “Most service centers either have eSignature authority or are in the process of moving away from managing paper technical documents into fully digitized workflows,” said Steven Devino, director of product marketing at CAMP Systems. “The CAMP ecosystem of products facilitates this transition by connecting the aircraft maintenance records to the service center floor, where up-to-date and accurate digitized technical documents are published electronically to the specific maintenance technicians performing the service via their mobile device.”

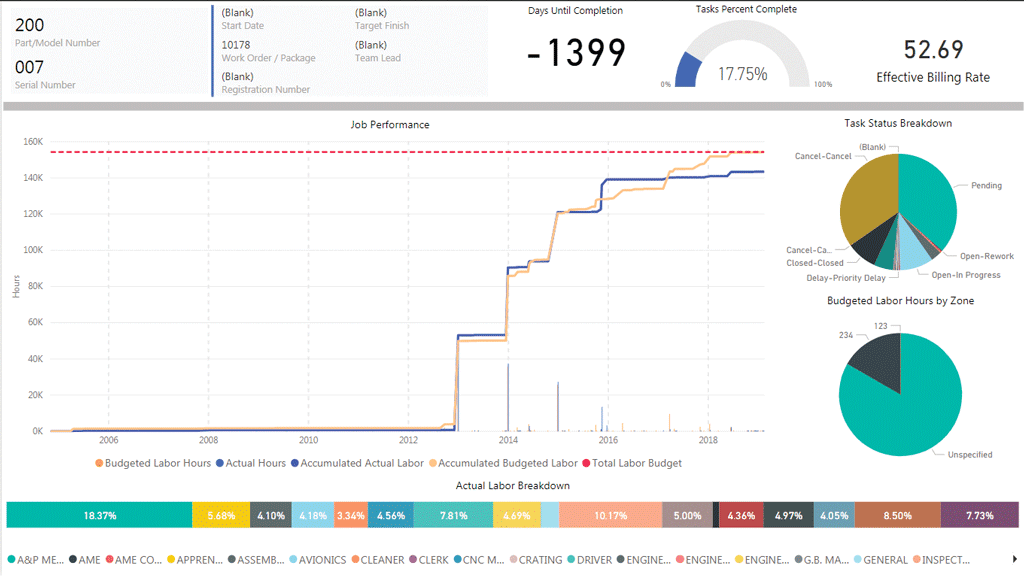

These kinds of benefits explain why digitized technical information is gaining ground in the aviation maintenance industry. “There is a new wave of technicians that recognize the need for paperless operations,” said Tautges. “Moreover, the typical MRO operator needs to use highly defined work processes where they can track the performance of each technician against a recognized service level and where the repair is underway. The paper process breaks when trying to determine such granular level labor recording. The digitized process does not.”

Addressing MRO Concerns

Digitized technical documents are literally electronic versions of paper-based documents, but they are much more than that. This is because the digital format allows the full power of information technology and the web to be used in capturing, storing, accessing, and updating this documentation.

CAMP Systems

For example, “our ERP allows for the digital imaging of OEM manuals related to the work and the cataloging of the revision of the manual being used,” Tautges said. “This is important in that the image of this specific manual can be attached to the work order and the catalog number registered as the manual supporting the work, which is an FAA/EASA requirement.”

Vendors in this space take responsibility for ensuring the accuracy of digitized documents.

“In our case, we proofread the documents against the paper versions if available,” said Thomas.

Added Kubinski, “in the CAMP ecosystem, the burden of digitizing and maintaining these complex manuals is handled by aircraft-specific analysts that ensure the digital documentation for OEM manuals, while AD/SBs are parsed to a task level and kept up to date for all aircraft operators to access through the CAMP MTX platform or for all service centers performing the maintenance on CAMP aircraft.”

At the same time, these vendors respect the privacy concerns of their MRO clients and the OEMs that they support. “Our policy on the ownership of data, as an ERP vendor, is that our customers own the data,” said Tautges. “It is up to our customers to determine and authorize with whom and what data to share.”

“There are certain manufacturers that will allow CAMP to store their documentation in our system and attach the docs to the tasks, but advise us not to make it visible to the end-user,” said Marc Gould, vice president of technical services at CAMP Systems. “Most of our OEM partners have no issue with CAMP sharing references and procedures for single cards, but prevent the sharing of entire manuals with the end-user.”

Maximizing Safety by Minimizing Human Errors

The use of digitized technical documents can help MROs reduce the occurrence of errors in their process — thus enhancing safety — while ensuring that these processes remain secure. After all, “any time manual data entry is required, human error can happen,” Tautges said.

Reducing manual data entry is built into the document digitization process, by populating these documents using software-driven digital solutions wherever possible. “The use of digital solutions to create the documents is vastly important due to the repetition of work that has to be accomplished using data sources to populate the results,” said Davison. “Such work can provide for the same service being replicated thousands of times in multiple locations anywhere in the world at the same time, at different times, or in any combination.”

Doing this digitally in an automated fashion minimizes the potential for errors, which is why vendors advocate this approach. “While we understand that human error is ever present, we do everything possible to eliminate such incidents,” he said.

In those instances where digital documents have to be manually modified by humans, “digital interfaces that have input warnings, mandatory fields, and predefined options are the most practical ways to improve safety and reduce human error,” said Schech.

Manual data entry isn’t the only source of potential human mistakes. “With frequent manual updates and AD/SBs from the OEMs and the paper tech docs being shared across the service center by multiple technicians, there is considerable potential for tech docs to get out of date, thereby opening the door for maintenance to be performed using outdated standards,” said Kubinski. In contrast, “digital technical documentation offers the accuracy of being connected directly to the OEMs’ standards and the efficiency of being kept up to date almost instantly. Additionally, digital technical documentation enables the entire maintenance operation to have access to the most accurate and current technical information as dictated by the OEMs regardless of their location, whether in their hanger, on the road, or preparing from home or hotel.”

Secure By Nature

The digitized documentation systems cited in this article have been built and are being maintained by companies with a passionate commitment to data security. As such, the storage systems that they use, plus the access platforms that they support, are designed to be ‘secure by nature’.

A case in point: “The Quantum ERP is a highly secure application which incorporates the latest security technology, including a rules-based security tree limiting access while supporting Multi-factor Authentication” Tautges said. Component Control’s ERP can be operated in a managed/hosted environment in the cloud (the most popular) as well as in an on-premise customer environment. “Both environments are highly secure,” he said.

Security is also built into Tdata’s products. “Customer records and publications are stored on a highly secure server environment,” said Thomas. “Customer records and documents can only be accessed by the subscriber. “

At Zook Aviation, “our host provider protects our infrastructure and our customers’ data with built-in security services that include unparalleled security intelligence to help identify rapidly evolving threats early, so we can respond quickly,” Davison said. “Our PCI compliance is put through rigorous testing once every 90 days, by third party security assessors who flag vulnerabilities and risks. To date, we meet all requirements and remain PCI compliant.”

A digitized technical documentation system also provides security during content transfers. “When implemented in a modern, secure and redundant software environment, the digital technical documents and their transfer from OEM to the technician are protected,” said Devino. This is not true for paper-based systems, which offer no guarantee of accuracy, completeness, or record of any historical changes. As such, “digitized technical documentation is far superior and orders of magnitude more secure,” he stated.

What’s Coming Next

Information technology applications are always advancing and evolving, and digitized technical document management is no exception to this trend. “Advancements in technology areas tend to bring better access, faster connectivity, and quite frankly more connection,” said Davison.“We have already eliminated the use of disc media and have become multi-platform to accommodate the end users access means, and have been fully cloud based since 2017.”

So what is coming next? The companies we spoke to offered a range of opinions.

“We are continuing to look at new technologies, both what can be developed and how we can partner with industry suppliers to deliver paperless solutions,” said Tautges. “We are also implementing Quantum to Quantum connectivity, which will allow our customers to work together without requiring off-line communication (i.e. email) and manage complete transactions within their ERPs.”

“Large technology companies are making great strides towards a ‘password-less’ future,” Thomas noted. “This technology will make its way into products in all publishing markets such as digitized technical documents, and allow for further control of content.”

Aircraft manufacturers are paying attention to the digitization trend in aviation technical documents, and some are adjusting their approaches to align with this trend. In fact, “OEMs are starting to discuss ways to streamline the technical document process by bypassing the manual efforts of monitoring the manufacturer’s publication database, downloading the publications, and then converting them to a useable source that’s saved and attached to the respective tasks, to just linking the manuals directly to the users of the manuals,” said Kubinski. In this digital way of doing things, “revisions will no longer need to be managed while the document linkage will be seamless, instantaneous and completely accurate.”

“The advancements coming will be for true end-to-end modernization, from the tear down of an aircraft through to the intricate details of inventory management, MRO and everything in-between,” Schech concluded. “The technology is available now to do exactly what customers want.”

The moral to this technological tale? The day will come when the idea of using paper based technical manuals will seem as quaint and outlandish as morse code keys and horse drawn carriages. That’s because the advantages of digitalized aviation technical documents are that numerous, and that profound.