The traditional paper trail associated with MRO repairs tends to be a long and complicated one, culminating in a blizzard of task cards that tell MRO technicians what to do and to record what they have done.

This is why the creation of electronic task cards has been a boon for the MRO industry. Not only are electronic task cards easy to access, read, and modify on the shop floor using workplace tablet computers, but the data they hold and capture can be easily stored and shared across the entire MRO enterprise. Among other things, electronic task cards can be used to track and document job progress, schedule sub-tasks, ensure that proper procedures have been followed through the use of automated checklists, record inspection signatures, and send data to the Billing Department when the work is done.

This is just some of electronic task cards’ positive impacts on the MRO industry and a glimpse at their potential to make this business more productive, efficient, and accountable. To gain an in-depth understanding of their benefits, Aviation Maintenance magazine spoke with top executives at three leading software companies; all of which incorporate electronic task cards into their end-to-end MRO documentation management platforms. These experts are Karl Steeves, CEO of TrustFlight (currently in a Proof of Concept phase); Saravanan Rajarajan, director of Aviation Consulting, Ramco Systems (already available); and Levi Schmidt, managing director of Customer Excellence at EmpowerMX (already available).

Saving Precious Time

No matter what business you’re in, time is money. This is doubly true with respect to the time spent on tasks that don’t earn income, such as filling out paperwork.

TrustFlight

Unfortunately, the mission-critical nature of the aircraft repair industry means that MROs spend a lot of time on paperwork. In fact, “when we analyzed where MRO engineers’ typically spend their time, we found approximately 50% of this time was spent completing paperwork and various compliance activities rather than working on aircraft,” said TrustFlight’s Steeves. “For us, the opportunity associated with electronic task cards is to reduce this percentage as much as possible, freeing up engineers and mechanics to spend more time doing actual work on the aircraft.”

Ramco

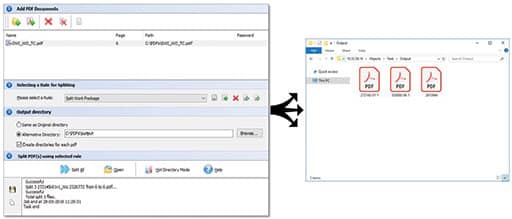

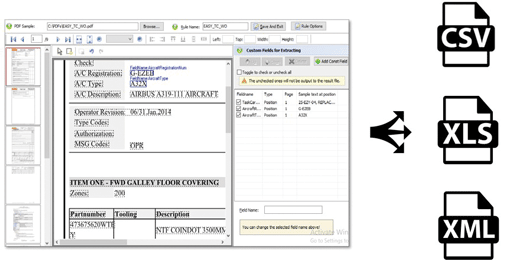

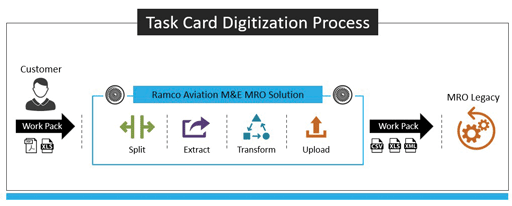

It’s not just record-keeping that consumes MROs’ precious hours. “Engineering and technical records departments also spend considerable effort whenever they deal with managing OEM technical documents and manuals,” said Ramco Systems Rajarajan. “This can be tasks like the induction of a new set of documents or manuals into their systems or managing revisions for their existing contents and manuals.”

If the incoming documents are PDFs, even more time can be lost converting them into a shareable interactive electronic format for work orders, unless the conversion can be handled automatically (as is the case with the Ramco Systems’ platform). “This is why pursuing a digital technical documentation program that uses electronic task cards has been proven to improve the operational efficiencies — not only within the engineering and technical records functions but across the downstream maintenance process,” Rajarajan said.

Using Advanced Tools to Improve Productivity

It may come as a surprise that electronic task cards are not a recent technological advance. In fact, “EmpowerMX has been providing electronic non-routine task cards for 20 years now,” said Schmidt.

EmpowerMX

However, electronic routine task cards are a new invention, he noted. “There has been a standard recently established — S1000D — which would allow broader adoption of electronic task cards by closing the gap for routine task cards in terms of their use in the workplace,” said Schmidt. “However, S1000D has a rigid framework that must be respected for compliance reasons. This makes S1000D somewhat difficult to adopt so that MROs can go 100% paperless.”

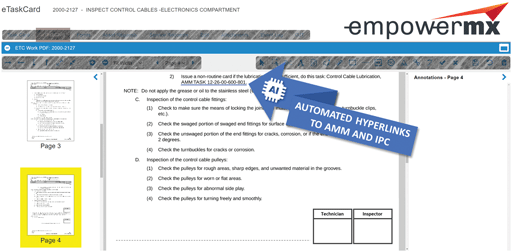

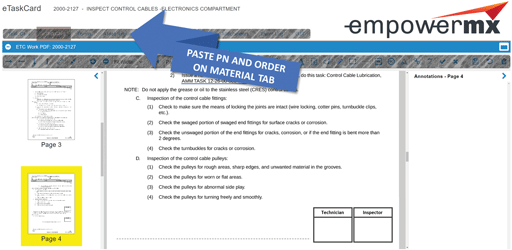

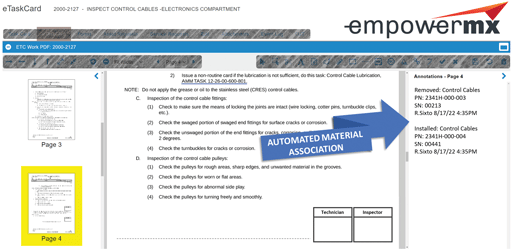

In response to S1000D’s constraints, EmpowerMX has created its own compliant routine task card application called eTaskCard. “With EmpowerMX eTaskCard, MROs can be 100% paperless,” he told Aviation Maintenance. “EmpowerMX achieves this by using the existing PDF task cards that every airline and MRO already uses, and then enables interactive functionality to sign off those task cards in the EmpowerMX application.”

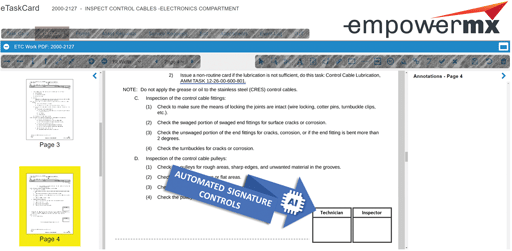

In both instances, advanced software tools such as artificial intelligence (AI) monitor the progress of electronic task cards and check for procedural compliance at every step. “AI performs two functions that help the technician maximize their productivity,” said Schmidt. “The first is that the AI error proofreads the job card: This means a block cannot be missed. A block cannot be unreadable. A stamp cannot be too light or too dark, and a non RII (Required Inspection Items) inspector cannot sign an RII required block. The time savings achieved by eliminating error corrections alone increases productivity.”

The second way that AI increases technicians’ productivity through electronic task cards is by eliminating the need for them to go back and forth to a desktop computer to look up manuals. “EmpowerMX eTaskCard automatically converts manual references for sub-tasks into clickable hyperlinks that show up on the electronic task card screen,” Schmidt explained. “When the technician gets to a step with a hyperlink, they just click on the link and read the sub-task from within the manual reference, all without leaving their task card app.”

tab of the eTaskCard. EmpowerMX image.

Similarly, an AI-enabled electronic task card can simplify the ordering of parts during a job. “When our EmpowerMX Materials Module is combined with the EmpowerMX eTaskCard, the technician can simply hyperlink over to the IPC (IIlustrated Parts Catalogue), copy the part number, paste the need into their electronic task card, and order their parts,” he said. “Since it’s all being done by this system, there’s no need to record the part information in the electronic task card. That’s all done in the background.”

Streamlining the Workflow

The MRO workflow is a complicated, often cumbersome process, due to the interplay of customer, compliance, and technical concerns that have to be documented and attended to. The adoption of electronic task cards can go a long way to streamlining this process, by making it faster and easier to execute while at the same time improving transparency and data sharing for all.

A case in point: “Electronic task cards can provide a way for engineers and mechanics to have direct access to work instructions generated by a Maintenance and Engineering (M&E) system alongside all supporting publication excerpts such as Aircraft Maintenance Manual (AMM) procedures,” said Steeves. “Once completed in the digital system, task card compliance data could be automatically fed into the M&E system to complete a task. Today, this is a manual process completed by technical records teams that takes a lot of time.”

It helps if this functionality is purpose-built into the system. For example, “EmpowerMX supports digital non-routine task cards as a matter of course,” said Schmidt. “By enabling eTaskCards on that pre-existing framework, the electronic task cards are automatically integrated into an already optimized workflow without having to take on any additional integrations or processes.”

Meanwhile, when it comes to precisely streamlining the integration of third-party task cards into an MRO data/task management system, “the first step in the process is to seamlessly ingest and process SGML/XML based documents complying to ISPEC 2200 and S1000D standards from the OEMs,” Rajarajan said. “The ingested task cards are then customized by the MRO through user-friendly screens to add additional texts, warnings, tables, formulas and graphics to the MRO’s own electronic task cards. Then, whenever the technician finishes the job, the complete task card with OEM and customized instructions are available on the MRO’s Point of Work internal website for reference and sign off.”

Improving Maintenance Tracking

Consistently executed, properly documented aircraft maintenance is a must for MROs and their aviation customers. This is why proper maintenance tracking is more essential than ever.

Electronic task cards satisfy this need nicely, improving both the accuracy and completeness of maintenance tracking. In fact, “electronic task cards can help improve maintenance tracking in several ways,” said Schmidt. In this system, no task cards can be lost since they are digital, and no pages can be scanned incorrectly when being recorded into the work order. “No steps can be missed when the AI requires them to be signed for, while parts that are ordered and used for a task do not get forgotten or incorrectly transcribed,” he explained. “All told, the use of electronic task cards is the most optimal approach to maintenance tracking, making it much more accurate and reliable. From a centralized production control booth, a team can see the status of any job throughout the facility, right down to the last step completed.”

On a larger scale, analysis of the data within the electronic task card system can be used as the basis for process improvement. “And if a technician notices something about the task or the data associated with the task, they can flag for the proper support at that moment,” Schmidt noted.

Electronic task card systems can also aid in tracking the completion of a scheduled aircraft maintenance check in progress, and in keeping an MRO’s maintenance forecasts up to date and correct in their M&E system.

“Tracking progress of a check can be difficult as information can’t be gathered until tasks are uploaded into the M&E system by tech records teams,” said Steeves. “Some rudimentary ways are used today including measuring the thickness of piles of completed and still-to-do task cards! In contrast, electronic task cards support real-time status updates on check progress.”

The same limitations of manual task card systems apply to maintenance forecasts and M&E system accuracy. “Audit and completion of a maintenance check cannot be finished until all task cards are uploaded and processed by records teams,” Steeves said. “When this is a manual process, there is often a delay along with errors in the data uploaded to the M&E system, leading to compliance and safety risks. Electronic task cards remedy this problem by providing validation at the point of data entry by the engineer/mechanic as well as updating the M&E system in real-time.”

Reducing Downtime, Improving Turnaround Time

Less downtime and faster turnaround time (TAT) was a priority for MRO customers – particularly airlines! – before COVID-19. In the pandemic’s wake, achieving both of these goals is more important than ever.

By making the MRO process more integrated, coordinated, faster and far less vulnerable to human errors, electronic task cards can help MROs hit both of these marks. Sometimes the improvements provided by electronic task cards are subtle but significant. “For instance, the system could highlight conflicts where tooling or access may be needed by multiple engineers,” said Steeves. By flagging these conflicts before they actually occur, electronic task card systems allow MROs to better plan their jobs, including the complex, more demanding major checks of commercial aircraft.

Taking a Big Picture view of the problem, Schmidt observed that, “Downtime/TAT is the byproduct of a technician’s ability to perform. When a technician doesn’t need to take time making corrections, or recording part number information, or going back and forth to the computer station, they are building efficiencies,” he said. Moving to an electronic task card system delivers all of these benefits, and thus less downtime/faster TAT.

“Time savings are also found when they don’t need to search for a job card because it now exists in cyberspace and can be accessed from anywhere,” Schmidt added. “The leads don’t need to organize and manage 2,000 job cards on a board. They don’t need to track those job cards down and hand them out or request a reprint because they can’t be located.”

Making MROs Leaner

The push to Lean process management is a top priority for profit-minded businesses, and MROs are no exception. Reducing costs while improving operational efficiencies boost the bottom line, and help MROs do better even in the toughest of economic times – like the last three years.

“Electronic task cards absolutely assist in the Lean process by reducing unnecessary movement,” said Schmidt. “For every hyperlinked sub-task, it’s a skipped trip to the computer station. For every part lookup and ordering, it’s a skipped trip to the computer station.”

“Paper task cards today record the hours to complete as filled in by the engineer/mechanic, which takes time and is generally not that reliable,” Steeves said. “Electronic task cards do better on both points, which aligns with the Lean process.”

“Electronic task cards enable mechanics to access technical documentation through mobile devices,” added Rajarajan. “This reduces considerable walk time by maintainers, which is consistent with Lean management principles. As electronic task cards also provide the capability for digital sign offs, the need to access paper documents for DFP are eliminated, thereby improving the task closure rate.”

That’s not all: “Shops and support teams also benefit by not having to transport paper task cards back and forth from the maintenance bay,” said Schmidt. “Planners don’t have to produce the cards and transport them to the bay. Those cards don’t then need to be organized for the leads to re-organize on a shift-by-shift basis. Production controllers don’t need to retrieve those cards from filing, scanning, and shipping.”

The takeaway: Electronic task cards and Lean management principles are a natural fit.

The Bottom Line

This article has gone into a great deal of detail to demonstrate one simple point: Electronic task cards are good for MROs and their clients.

It is safe to say that this point has been proven.