The fast-paced digital transformation of the aviation industry, coupled with the emergence of new propulsion technologies is challenging the aviation maintenance training industry as regulators drag progress into the future of aviation maintenance.

While colleges, engine and airframe manufacturers and MROs such as Lufthansa Technik Training (LTT) and Air France Industries KLM Engineering & Maintenance (AFIKLM E&M) are adopting new training technologies such as Virtual Reality (VR) and Augmented Reality (AR), the critical aviation maintenance school ecosystem is being held back despite the fact FAA has been congressionally mandated to reform Part 147 training. The mandate passed last December, part of a decades-long effort to bring maintenance training into the 21st Century, but has yet to be implemented.

Brave New World

Companies are adopting new technologies for which trainees must prepare.

For instance, Safran contracted with Librestream to adopt its Onsight augmented reality platform for remote customer support. Safran Helicopter Engines first launched a remote assistance service called Expert Link in early 2018. The instant expert connection for technical diagnostics and preventive maintenance tasks through a live video and audio feed accounted over 1,000 visual assistance calls covering 40 countries per year.

Jasoren is also offering remote maintenance using augmented reality to provide remote workers with real-time, AR-based assistance through video calls with experts, shortening maintenance downtime while reducing travel expenses and errors, said the company. In training, it is more engaging and interactive with real-time remote guidance by experts, increasing the effectiveness of onboarding and training sessions

Similarly, aircraft painters with the Air Force 588th Aircraft Maintenance Support Squadron Corrosion Control shop, are using a virtual reality paint training allowing hands-on time in a controlled environment simulator to reinforce the skills learned in class.

Many have already deployed virtual maintenance trainers (VMTs) offering students 3D training scenarios through which to learn aircraft systems and troubleshooting. For instance, Airbus uses a VR headset, touchpads and infrared cameras enabling inspection and repair within the VR environment.

FlightSafety International (FSI) has Virtual Aircraft, an immersive 3D learning experience assisting students and instructors in exploring the aircraft as if they were out on the flight line. These true-to-life interactions with the aircraft’s various components happen in real time. FSI indicated the technology results in higher retention, an increase in transferable skills and competency.

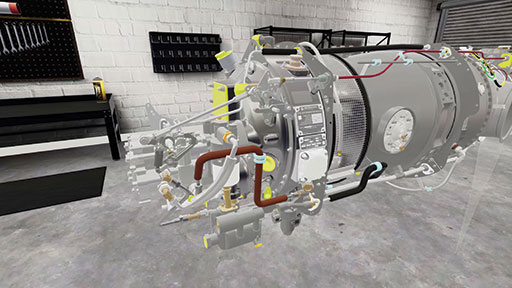

FSI also has Virtual Engine Trainers, a real-time, interactive/animated models of Pratt & Whitney engines allowing manipulation of the engine and inner workings in any position or system grouping. Students can even change parts.

“X-ray and move functionality further enable students to view dynamic cross-sections into nearly every engine part,” FSI wrote. “Borescope inspection training is also available with typical wear and tear simulation throughout the engine, allowing students to practice damage assessment and engine dispatchability. EASA has approved Virtual Engine Training as a method of assessment in up to 50 percent of practical engine training.”

Through its LiveLearning delivery method, FSI offers clients a hybrid classroom – both in-center and remote, according to SVP Operations Brian Moore. “This allows for the same collaboration and discussion you would have in a traditional in-center course,” he told Aviation Maintenance.

Industry Wants High Tech Training Shifted to Training Environment

Industry has spoken with a single voice it wants better prepared aviation maintenance technicians. It signaled a requirement for super technicians able to work across avionics, airframe and engine disciplines. Finally, there is growing concern restrictive curricula will hamper integration of new propulsion technologies and advanced air mobility.

Aviation maintenance schools have been so hamstrung by highly prescriptive, antiquated training regulations that they spent almost two decades trying to change within the FAA. In frustration, Aviation Technical Education Council members developed modern curricula that would achieve the same competency outcomes and enable the adoption of new and innovative technologies. Congress used it to mandate the long-overdue FAA changes. It also allows for the adoption of new programming to accommodate emerging technologies and the expansion of the aviation maintenance training industry footprint to satellite facilities such as high schools and community colleges, necessary to address the mechanic shortage.

For instance, big data analysis and predictive maintenance has never been part of the FAA required curriculum and won’t be part of the FAA mechanic certification standards (at least in the short term) when they are published. But, Crystal Maguire, ATEC executive director, said schools will have the flexibility to add content to their coursework once the new rule is published.

“We need to reform Part 147 regulations in order to give more academic freedom to teach students,” Joel English, executive vice president at the Aviation Institute of Maintenance said. “There is evidence that the FAA is listening so schools are preparing for the day they are able to apply professional judgement and academic flexibility to our programs, which is severely limited today.”

The system is based on an hourly metric rather than proven competency but even that is complex.

“Though there is only one set of guidelines for part 147 schools, the individual Principal Maintenance Inspectors (PMIs) at the local FAA offices often interpret these rules differently. Though we have one standard curriculum taught at all 14 of our campuses, PMIs often interpret FAA rules differently and force our instructors to change the standard curriculum to fit a PMI’s own individual opinion. That means that we must adapt the standard curriculum differently at our different locations to meet the desires of the individual inspector. The FAA gives us a standard, we build one curriculum to meet that standard across the country, but the individual field officers make us change to meet their interpretation of the standard! It’s a challenge that will be overcome when the FAA allows us to apply our own professional judgement to the curriculum development process to accommodate the needs of the employers who hire graduates.

“Students will still be expected to attain the same outcome – passing the FAA certification exams to become a certificated A&P mechanic,” he continued. “But schools will have the ability to focus on what employers are requesting, and re-orient the instruction with some degree of academic freedom.”

There is more flexibility at the university level, English said because they go beyond the 1900-hour prescription and teach additional content such as VR and other innovations. “The FAA neither regulates nor cares about this material,” he said.

To increase student preparedness, AIM includes an additional Capstone course, which is beyond the FAA’s 1,900 hours, and includes an adaptive learning platform and VR within that instruction.

Covid Accelerates Innovation

“Covid definitely changed our training methods and sped up everything,” Zonda Feulner, Pratt & Whitney director of customer training, said. “We became more agile and creative. We quickly adapted our Engine Explorer Application from touch screen to using a mouse for remote learning and so we could pivot to AR and VR as needed because that is where a lot of our customers are going.”

FSI worked to get distance learning approved by regulatory authorities, resulting in increased efficiency and cost savings as such instruction moved online.

Aviation Maintenance previously reported L3Harris sees a 20 percent reduction in maintenance training costs with AR/VR/MR (mixed reality) training. More importantly for the aviation mechanic shortage, L3Harris increased student throughput fourfold with virtual training and projects it can achieve 30- to 50-percent reduction in training times with further enhancements to its learning management system.

Boeing also demonstrated the value of the technology with the same outcomes as working actual aircraft. Finally, GE found task performance time declined 10 percent and increased job satisfaction by 85 percent.

The Evolution of AV MX Training

As aircraft and aviation maintenance professionals evolved so too has aviation maintenance training, said FlightSafety International SVP Operations Brian Moore.

“Our work with OEMs has allowed us to remain on the cutting edge of advances in aircraft,” he said. “We use a combination of real engines and components, and immersive training tools like our virtual engine and virtual walk-around to ensure each technician is highly skilled and able to troubleshoot effectively.”

The Covid changes are the latest in the evolution of maintenance training beyond classroom instruction, according to AFIKLM E&M’s Wanda Manoth-Niemoller, commercial development manager, who noted AR use-cases are built in cooperation/partnership with other parties. Similarly, the company is studying cases incorporating combinations of Artificial Intelligence (AI) and big data in operations, as well as remote support.

AI is already the pilot training realm which can be applied in aviation maintenance training. The idea is to give students immediate data-based feedback on performance and identify areas where continued work is needed so students can master that work to ultimately gain competency. This immediate feedback is expected to improve competency and reduce training time. It is already using to track whether a trainee picks up the wrong tool and how often.

“We started off with our maintenance simulation training device on a laptop or desktop, with which we are able to save up to 50% training time on practical on the actual aircraft,” Manoth-Niemoller told Aviation Maintenance. “With part 145 courses we are able to do 100% simulation. After the desktop simulation, we introduced VR in both part 145 as well as part 147 courses. The latest addition is AR, which we currently use to explain system behavior in the 777 and to do 100% of the practical for the engines on the 777 and the 787 in AR. The first business cases are now in development to introduce AR in the MRO operation. Also, in VR we are still developing such things as engine run up 2.0 and 360 VR which are made in cooperation with the schools, to use in part 66 training.”

“In general, ours has evolved by inserting new technology into instructor-led, hands-on training,” Feulner told Aviation Maintenance. “That goes hand in hand as engineering progressed. We started six years ago by creating our Engine Explorer Application for the GTF, V2500, and the JSF, displaying a 3D model students can manipulate to isolate different systems and search for different parts. This enhances the classroom portion and increases class participation. Once we created that foundation and built the 3D models, we switched over to VR training to test students. It allowed us to provide the support items, such as animation on how to do a specific task if they are having a tough time.”

Supplementing Online Training

Not all training can be done online, however.

“I believe that nearly half of the part 147 program could be taught effectively online, but I have found that my students prefer face-to-face instruction,” said English. “I’ve created a wide range of online simulators within many different academic situations, and my students want the real thing. We recognize students who want to become aircraft mechanics generally want to be in a hangar, with tools and equipment, alongside classmates and a seasoned instructor.

“I think that augmented and virtual realities are probably best for theoretical understanding of the anatomy of aircraft and for general familiarity of aircraft systems,” said English. “As technologies get better, I’m sure there will be some manual processes that can be virtualized, but I believe that AR and VR teach the mind, not necessarily the body. Something important happens when a student strikes an arc in a welding booth and not only sees the machinery respond but also smells the fumes, feels the heat and registers the resistance of the flame change when it touches metal that a computer cannot yet tell them; when they struggle to push an aircraft onto a scale and feel the bounce of the tires moving into position, they are learning something that an online simulation won’t tell them. I believe becoming an aircraft mechanic is a process of tactile engagement as much as theoretical learning. The subtleties of work in an aircraft hangar and the physical feedback that tools and machines give the budding mechanic just can’t be efficiently replicated on an iPhone or in an Oculus headset. That simple, satisfying ring of a ratchet, singing like a stainless-steel cricket in one’s hand, speaks to a mechanic. Entering a username and trying to remember a password is not the mechanic’s language.”

Even so, there is no question online learning is here to stay.

“We see Online Distance Learning (ODL) as a game changer in future education,” Lufthansa Technik Training head of sales, key account management & marketing Harald Schween told Aviation Maintenance. “ODL has become an important part of our maintenance training portfolio. And, beyond online maintenance training, we expect blended-learning methodologies to become more relevant in the industry such as a combination of modern e-learning media with classroom and online training sessions.”

For LTT, it’s all about aligning its methods and tools to the requirements of customers. “We are convinced that VR, beside other digital solutions, will play a some role in future maintenance training,” said Schween. “With VR we can give the trainees a better understanding of the complexity of an aircraft and can give them the chance to (virtually) touch components of an airplane. Through VR technologies we can show how the aircraft looks and we may use VR to complement deeper level maintenance training. Furthermore, we may have the possibility to bring practical elements into the classroom virtually to decrease the amount of physical practical training days at the aircraft.”

Schween sees little progress at EASA to adopt new learning methods into regulations (Part-147, Part-66). “Hence, there are no formal benefits, such as credits to a EASA Part-66 CAT A or B program, through the application of eLearning, digital media or VR. On the other hand, the regulators have recently incorporated distance learning methodologies, such as video conferencing, into maintenance training requirements. This has been done in a very flexible and industry-oriented manner. We strongly believe this positive experience and fruitful collaboration between industry partners and the regulators will be continued for the implementation of digital tools and solutions in the future.

“The transition from ‘traditional’ classroom training to new learning methodologies changes teaching significantly,” he continued. “For example, instead of instructor-led lectures, the instructor becomes more a coach, guiding them throughout their learning path and experience. Instructors and trainees have to deal with new tools and methodologies such as handling of digital media and tools within a modern blended learning environment and we strongly believe in the benefit of ‘blending’ traditional and digital learning methodologies.”

Much to be Done

Even as industry continues to adopt new training technologies, the fact remains there is much to be done to bring the entire aviation maintenance training ecosystem to the same level. With part 147 reform in the United States and similar efforts on the international front, there will come a time when that happens, but it can’t come fast enough given the speed with which different facets of the industry are moving.