Lufthansa Technik has recently enhanced its AVIATAR digital platform with various new digital fleet management applications for the Boeing 737 NG, which are now made available to 737 operators around the world. The new Condition Monitoring and Prediction offerings were co-created with United Airlines, which partnered with Lufthansa Technik starting in early 2021 on the 737 NG and Airbus A320 family to jointly develop unique predictive maintenance solutions by combining world class engineering know-how and industry leading data science teams.

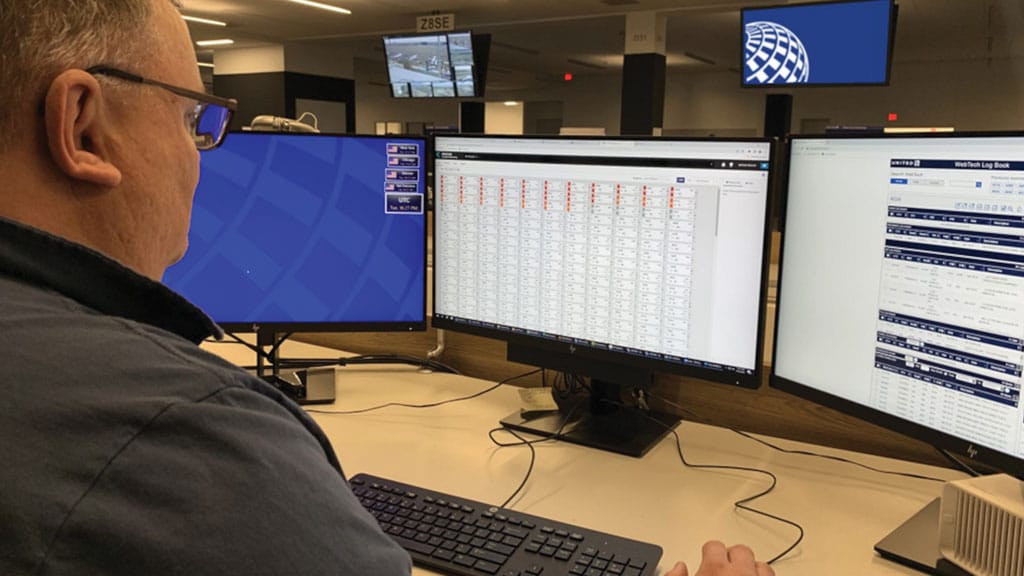

By integrating the Boeing 737 NG into AVIATARs Condition Monitoring troubleshooting solution, United Airlines and all other customers can now manage technical operations for their Airbus and Boeing aircraft side-by-side on a single screen. In addition, they can now benefit from a growing number of Predictive Maintenance use cases developed for the Boeing 737 NG that help to avoid unplanned maintenance events or AOGs (Aircraft on Ground). AVIATAR now also offers integration with United’s M&E (Maintenance & Engineering) system logbook and embeds OEM documentation linking features for the 737 NG amongst other new features.

“As one of the world’s largest airlines, we are proud to see our world class engineering and industry leading data analytics teams contribute to the success of this service,” said Kurt Carpenter, United Vice President of Technical Operations Planning and Strategy. “Our goal entering this effort was to focus on operationalizing new predictive maintenance alerts and data to provide decision support and prescriptive maintenance outputs to our frontline teams.

AVIATAR team and United teams worked to consolidate Condition Monitoring and Predictive Maintenance alerting for the 737 NG and A319/A320 fleets into a single platform in just one year. Our Digital Technology teams also collaborated to integrate our maintenance logbook, in-house predictive alerting and technical manual workflows. We look forward to continuing this relationship and to co-developing new and unique predictive maintenance models with the AVIATAR team.”

“By using Condition Monitoring, United is the first airline in the Americas that uses the full extent of seamless Boeing and Airbus efficient troubleshooting with a fleet of over 500 aircraft on the AVIATAR platform,” said Georgios Ouzounidis, Lufthansa Technik Head of Corporate Sales for the Americas. “Our AVIATAR team did an excellent job in customer centric development and customized the interface to United’s Maintenance software adding a new interface into our open system landscape. The outstanding and successful transatlantic cooperation and teamwork during the pandemic between the digital teams of AVIATAR and United’s Tech-Ops, is an excellent blueprint for partnership projects in digitalization, Tech-Ops and MRO.”

Based on aircraft and maintenance data, Condition Monitoring provides an overview of the overall operational aircraft condition. The immediate detection of faults increases troubleshooting efficiency and enables proactive corrective actions leading to higher aircraft availability. With Condition Monitoring aircraft data (e.g. from the central maintenance computer, the aircraft condition monitoring system, or the aircraft movement message) is collected via the Aircraft Communications Addressing and Reporting System (ACARS) or SITA network and visualizes the aircraft status and flight schedule. In addition, this health data is combined with work orders and position data. Condition Monitoring provides customizable alerts and notifications on aircraft or fleet level as well as for Air Transport Association chapters. Thus, the user gains an excellent overview of potential corrective actions for respective maintenance and repair operations.

Launched in 2017, AVIATAR is the independent platform for digital products and services developed by Lufthansa Technik. The platform offers its users digital solutions ranging from predictive maintenance to automated fulfilment solutions. AVIATAR combines fleet management solutions, data science and engineering expertise to provide a comprehensive range of integrated digital services and products for airlines, MRO companies, OEMs and lessors that seamlessly integrate with physical fulfilment in TechOps and beyond.

For more on predictive maintenance see our feature story starting on page 16.