By Rick Williams, Kaman Precision Products

Space lasers are transforming the world. Not the far-off future of science fiction, but the universe of how data and communications flow today — everywhere from deep space missions to countless applications here on earth, including consumer internet services, military operations, and banking transactions.

Lasers can transmit vast amounts of data over great distances at the speed of light, 100 times faster than previously possible in space. The narrowness of the light beams makes laser communication remarkably efficient. The highly focused light is aimed at the receiver, resulting in minimal beam divergence and signal loss and allowing for reduced power consumption.

Staying on Target

Indeed, this narrowness of the laser beam also presents daunting technological challenges. In space laser communications, impeccable precision is needed to align transmitters and receivers across vast distances as the terminals move at varying speeds and directions — a level of accuracy comparable to hitting a three-point basketball shot from 100 miles away.

Engineers have addressed these challenges by developing fast steering mirrors (FSM) controlled with extremely sensitive sensors. These systems keep the beam precisely on target for satellite-to-satellite and ground-to-satellite links and deep-space communication, facilitating accelerated growth in the flow of data around the globe.

For all its benefits, optical communications still face several challenges. Unlike radio communications, which can be sent out in a broad beam blanketing target areas with its signal, optical communications are sent in a relatively narrow beam pointed directly at a receiver. When broadcasting from thousands or millions of miles away, an optical communications telescope pointing must be extremely precise. A deviation of even a fraction of a degree can result in the laser missing its target entirely.

https://www.nasa.gov/directorates/heo/scan/opticalcommunications/challenges

The Galactic Network

These capabilities — laser communications with FSM tracking — are bringing us closer to what might be called the “Galactic Internet.”

That was the imaginative term coined in the early 1960s by J. C. R. Licklider, the first director of the Information Processing Techniques Office (IPTO) at the Pentagon’s ARPA, to describe the possibility of a digital “network” open to all that would serve as “the main and essential medium of informational interaction for governments, institutions, corporations, and individuals.”

ARPANET became the first wide-area packet-switched network with distributed control and proved instrumental in shaping modern computer networking and the internet.

Copper Couldn’t Satisfy the Insatiable Demand for Bandwidth

In the early days of the internet, most data was transmitted over copper cables, taking advantage of ubiquitous telephone networks. However, electrical transmission over copper suffers from signal attenuation due to resistance in the conductor and dielectric losses.

As the internet evolved from text-based emails to images, videos, and games, the standard 56.6-baud dial-up modems became obsolete, and internet service providers (ISPs) and backbone networks needed new transmission methods to keep up with the tremendous surge in data traffic.

Fortunately, as computer scientists were creating the internet, the field of photonics was developing a method of using light to transmit data much faster and over much longer distances than what is possible with electricity conducted through copper wires.

Fiber Optics Enabled the Growth of the Internet

The first continuously operating helium-neon gas laser was demonstrated in 1960, and a decade later, scientists at Corning Glass Works invented ultra-transparent glass that could be mass-produced into low-loss optical fiber. By 1977, fiber optics began to carry traffic over public telephone networks. and in 1986, Sprint deployed the first nationwide 100% digital fiber-optic network.

Optical fibers can transmit up to 60 Terabits per second, more than 700 times faster than copper. And the data quality is superior because the optical signal is not subject to electromagnetic interference and radio-frequency interference (EMI/RFI), crosstalk, and impedance problems that cause signal distortion and loss with copper.

A watershed moment came in 1986. The invention of the erbium-doped fiber amplifier (EDFA) significantly increased the distance an optical signal could be transmitted before requiring an electronic repeater, making fiber optics practical and economical for intercontinental undersea cables. Previously, submerged copper cables operated at only 140 megabits per second and required powered electronic repeaters at frequent intervals.

The first transatlantic fiber optic cable went into operation in 1988 — a year before Tim Berners-Lee proposed what became the World Wide Web, causing a further explosion of internet traffic. Today, submerged optical cables carry 95% of the world’s data traffic. Each single fiber has a bandwidth in excess of 1 terahertz, one thousand times greater than what is possible with copper wire.

Free Space Optical

Fiber optics enables significantly higher data transmission rates, over longer distances, compared to copper wire. But fiber optics is limited by the length of the strand of fiber. What if the benefits of optical data transmission could be untethered from this physical limitation, extending thousands of miles through space?

Laser communications, also known as Free Space Optical (FSO) communications, utilizes much of the technology developed for fiber optics to wirelessly transmit data through air, vacuum, or outer space. FSO is reliable over vast distances when the light propagates in space for inter-satellite and deep space links.

Over the past five to ten years, satellite cost performance has, in some instances, improved more than 1,000 times, and satellites produce and transport much more data than ever before. There are few parallels for a disruption of this magnitude, except the transition from mainframe to desktop computing in the 1970s and 1980s.

McKinsey & Company, The role of space in driving sustainability, security, and development on Earth, May 2022

Unfortunately, here on Earth, atmospheric factors such as fog, rain, dust, heat, and even birds pose significant challenges to Free Space Optics (FSO) technology. These factors lead to signal failures and unacceptable error rates and limit the feasibility of long-distance point-to-point optical links between terrestrial terminals.

In the early 2000s, companies like Terabeam, AirFiber, and CableFree invested significant sums in FSO as an alternative to fiber optics. However, none of these ventures could overcome the challenges posed by atmospheric conditions to establish commercially viable services.

Terrestrial laser internet service is experiencing a resurgence, with deployments in 13 countries, including Australia, Kenya, and Fiji. In June 2023, Alphabet, the parent company of Google, unveiled its ambitious plans for large-scale implementations in regions of India and Africa, where fiber optics is difficult to deploy, aiming to provide up to 20 Gbps bidirectional throughput within a 20 km range.

Space Lasers Vastly Outperform RF

These distance limitations do not exist in the “free space” beyond the Earth’s atmosphere. Lasers perform exceptionally well over great distances, in the vast emptiness of space, far more efficiently than what is possible using radio frequencies (RF).

Before the advent of FSO, all communication in space used radio and microwave bands, regions of the electromagnetic spectrum with the longest wavelengths and lowest frequency. NASA beamed TV signals from the moon using the S band (2–4 GHz), and later the X band (8–12 GHz) and the Ka band (27–40 GHz) provided faster transmission rates. NASA’s Deep Space Network currently achieves speeds up to 50 Mb/s with the Ka band.

No More RF Red Tape

Before you even start thinking about launching your satellite you need to apply for a license from every country you want to send an RF beam down to. You have to pay the costs associated with each licensing regime. Then you have to wait. And wait….

Laser communication is not regulated by the International Telecommunication Union and it can be used without restrictions and does not require costly licenses. The reason for this is that its inherent small beam size avoids interference issues and renders any restrictive regulation in the future highly unlikely.

https://mynaric.com/technology/licence-free/

The low transmission rates are not the only disadvantage of RF: radio signals spread out as they travel, causing two additional problems. The first is the overcrowding of the RF spectrum which causes the overcrowded RF airwaves causes interference, interception, or jamming, and the scarcity of available spectrum severely restricts the expansion of services.

The second problem is that beam divergence causes significant attenuation of the RF signal. The farther the distance, the weaker the received signal. To compensate, transmitters and receivers are enlarged, and power consumption increased, placing costly demands on satellites and spacecraft. RF ground stations have antennas as large as 230 feet (70 meters) in diameter.

Advantages of Space Lasers

Laser communications offer an effective solution to these challenges and limitations of RF.

Bandwidth – The primary advantage of laser communications compared to traditional RF signals is a dramatic increase in bandwidth. Space lasers use non-visible infrared radiation (IR) portion of the electromagnetic spectrum has frequencies ranging from about 300 gigahertz (GHz) up to about 400 terahertz (THz). The higher the frequency, the more data is encodable in the waveform, resulting in effective bandwidth increases of 10 to 100 times compared to RF.

Low Latency – Faster doesn’t just refer to the increased data transmission per second. Laser communications also achieve a significant reduction in latency with near-instantaneous data transfer with delays 10-20 milliseconds, compared to the hundreds of milliseconds experienced with RF.

No Spectrum Congestion – The short wavelengths (less than 0.1 centimeters, compared to RF wavelengths of 0.8 to 15 cm) and the highly focused beam frees FSO from the many headaches and limitations of spectrum overcrowding. Laser communications links do not interfere with each other, and therefore the possibilities for expanding FSO in space are practically unlimited.

SWAP – Another important benefit of the tightly focused beam is that laser light does not spread out the way radio waves do, allowing optical signals to maintain their strength over great distances. Less beam divergence and attenuation mean more of the transmitted power is captured by the receiver and less power is wasted. According to NASA, “optical communications provides decreased size, weight, and power requirements. A smaller size means more room for science instruments. Less weight means a less expensive launch. Less power means less drain on the spacecraft’s batteries.” These benefits extend to equipment on the ground: laser communications receivers can be up to 44 times smaller than current radio antennas.

Security – The narrow beams also make laser signals extremely difficult to intercept. Moreover, space lasers use light and photonics, and therefore Quantum Key Distribution (QKD) can add unmatched levels of security to these communications.

Revolutionary New Services

During the era of RF space communications, most data traffic heavily relied on geostationary (GEO) satellites. Positioned at an altitude of 35,786 km (22,236 mi) to maintain fixed locations above the equator, these satellites offered stability and efficiency by ensuring coverage across a significant portion of the Earth’s surface with just two or three satellites. However, these GEO satellites were large and costly, and the RF transmissions over such long distances resulted in significant latency.

The alternative, low earth orbit (LEO) satellites at altitudes of 60 to 2,000 km (99 to 1,200 mi), reduces signal propagation delay, but many more LEO satellites — several hundreds or thousands of satellites — are required to provide continuous coverage depending on the altitude. The velocity of LEO satellites, moving at around 17,000 miles per hour relative to a fixed point on the Earth, adds considerable complexity to maintaining data communications links.

Laser technology significantly enhances the functionality and economic viability of the various types of satellite systems, unlocking new possibilities and expanding the realm of what is feasible. GEO satellites can now provide high-speed, low-latency communications, and the radical improvements in SWAP of laser compared to RF systems make large constellations of LEO satellites more economically viable to build and launch.

Networking LEO and GEO

Optical communications also facilitate the networking between satellites at different altitudes to achieve efficiencies and optimize specialized tasks. For example, the U.S. National Defense Space Architecture (NDSA), which has since been renamed the Proliferated Warfighter Space Architecture (PWSA), is developing a network topology composed of two separate constellations: the Transport and Tracking layers, connected by optical links.

The Transport Layer is a resilient mesh network in LEO that allows information to flow quickly and securely around the globe and connects to ground stations. Mesh satellite networks provide resilience because data can be rerouted if one satellite is compromised or destroyed. The second constellation, the Tracking Layer, does remote sensing and observation, with infrared sensors to spot and track missile threats.

Another example of using laser links to network LEO and GEO satellites is the SpaceDataHighway (SDH), a public-private partnership between the European Space Agency and Airbus. The commercial service utilizes the European Data Relay System (EDRS) to provide high bandwidth capability to LEO satellites and airborne platforms by means of optical communications via the EDRS-A and EDRS-C geostationary satellites and ground stations in Europe.

Proliferated Commercial Satellite Constellations

Starlink, an ambitious project initiated by SpaceX, has made notable strides in its mission to provide high-speed internet to every corner of the globe. As of July 2023, 4,487 Starlink satellites are operating in low Earth orbit, with the newest versions of the satellites networked to each other with lasers. SpaceX anticipates the total number of satellites in the Starlink network to grow to between 12,000 and 42,000 eventually.

SpaceX founder Elon Musk tweeted last year, “Laser links in orbit can reduce long-distance latency by as much as 50%, due to higher speed of light in vacuum & shorter path than undersea fiber.”

The Starlink project is groundbreaking and transformative, but it is not without competition. One of the biggest competitors is OneWeb, a UK-based company that also aims to build a satellite network for global broadband service. Another formidable rival is Amazon’s Project Kuiper, which plans to deploy over 3,000 satellites for similar purposes.

Furthermore, China’s state-run space agency is also working on a global broadband service called Tianlink. Each of these competitors brings unique strategies and resources to the table, thereby contributing to an increasingly dynamic and competitive landscape in satellite-based internet services.

Aiming the Narrow Laser Beam

All these developments depend on the remarkable quality of laser light — the extraordinarily straight and narrow beam of light that can be focused on a distant target, transmitting data at incredible speeds and low latency, with minimal signal loss due to beam divergence.

And yet, it is the narrowness of the laser that makes it so difficult to acquire and maintain a line-of-sight link over distances of thousands of kilometers.

Aiming the transmitter and receiver is challenging due to the extreme precision required and because the system must quickly and smoothly adjust as the host satellites and spacecraft move at high velocity in different directions relative to each other and to ground stations. And the high-precision components must reliably stand up to the rigorous demands of space launches and the harsh space environment.

Fast steering mirrors require precision position data to rapidly adjust mirror position, which is usually actuated by electromagnetic voice coils. Extremely sensitive sensors can accurately measure the mirror position with extremely fine resolution in the sub-micron range.

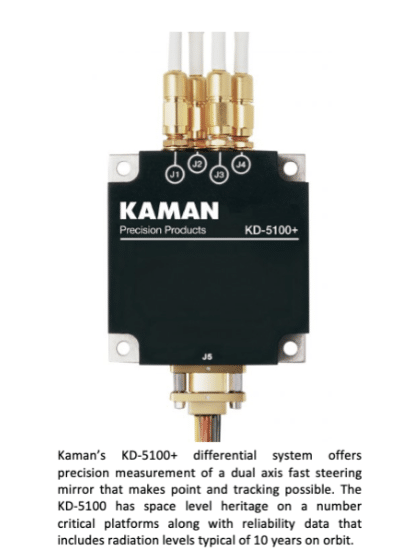

The system is designed so that the performance of the sensors remains unaffected by the severe temperature fluctuations in the space environment. As shown in Figure 1, electronically matched sensors, using eddy current technology, are positioned in pairs on opposite sides of the pivot point of the mirror and equidistant from this point.

The sensor-to-target relationship is such that as the target moves away from one sensor, it simultaneously moves towards the other an equal amount. The two pairs of sensors are positioned in two axes set perpendicularly to provide precise x-y tilt/tip position data. Operating in differential mode, the sensors eliminate or reduce common mode effects, such as piston action, and signal noise.

Taking Aim at the Future

Kaman Precision Products, through its Measuring line of business, developed its line of differential position measuring systems over 30 years ago. Kaman has continually refined the performance capabilities of these renowned products to meet the increasing requirements of the space and defense markets. The product line now boasts three exceptional products including the KD-5100 family, with over 100krad TID capability and a rich 3-decades space heritage including the Mars 2020 Rover, as well as its COTS version, the DIT5200L, a low noise, affordable LEO-capable system, and our new digital KD-5690 system. Learn more at kamansensors.com/industry/space/ (https://www.kamansensors.com/industry/space/).