EnduroSharp Aircraft Maintenance Tools want to help with the goal of sustainability in the aviation industry. Lowering the aviation carbon footprint is necessary the company says, and they are making it their goal to help reflect a zero-waste philosophy.

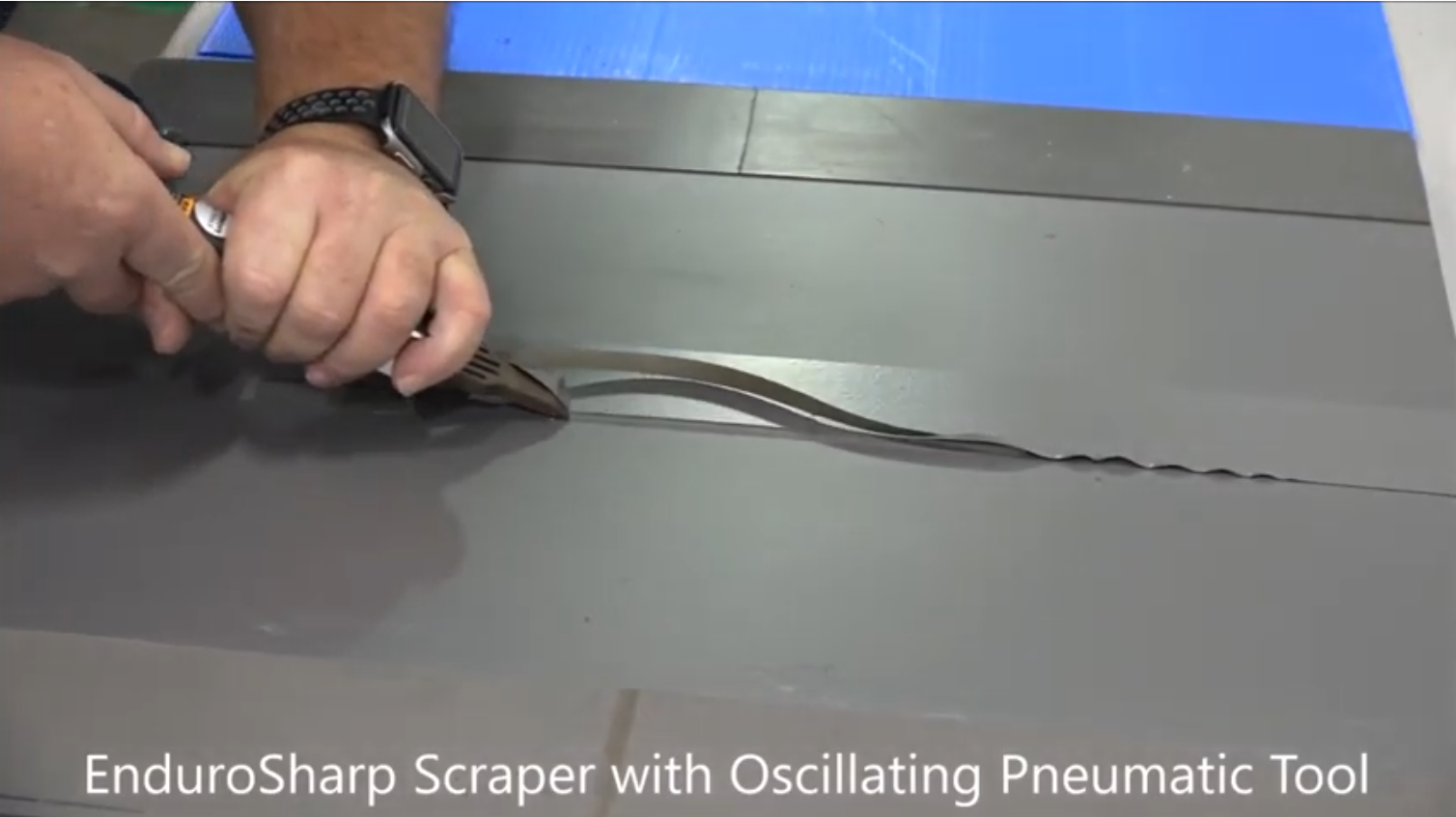

The EnduroSharp Product line is used to repair and maintain aircraft structures. The product line consists of non-metallic removal tools that will not cause damage your aircraft during the sealant, adhesives, and coating removal process. The EnduroSharp nonmarring aircraft maintenance tools are made from Torlon, a high-performance plastic that creates a durable tool that will hold a superior edge. Creating an effective tool for aircraft maintainers that will not damage aircraft structures, like aluminum and composite is their aim, which will “allow your aircraft structures to last longer.”

“For decades, aircraft maintainers have searched for a non-metallic sealant and coatings scraper that would hold an effective edge, but not pose a threat to aircraft structures, like aluminum and composite. They’ve tried sharpened acrylic, polycarbonate, phenolic, and fiber reinforced plastics of all kinds. Nothing has really worked, and often maintainers have resorted to sharpened putty knives, scribes, and utility blades. Finally, a non-metallic blade system comes along that actually works. The Torlon scraper system is like “The Holy Grail” of non-metallic scraper blades. No toolbox for working with removal of coatings from composites and sensitive structures should be without them,” says an aerospace repair developer client.