Jeff Guzzetti is the president of Guzzetti Aviation Risk Discovery (GuARD), an aviation safety consulting firm that he formed following a 35-year career with the National Transportation Safety Board (NTSB), Federal Aviation Administration (FAA) and other agencies. During his 18 years at NTSB, Guzzetti was a field investigator, “go-team” engineer and Deputy Director. He then served as an Assistant Inspector General at the Dept. of Transportation and testified before Congress regarding aviation safety audits. In 2014, Guzzetti served as the Director of FAA’s Accident Investigation Division in Washington, DC until his retirement in 2019. He is a graduate of Embry-Riddle Aeronautical University with a degree in Aeronautical Engineering and holds a commercial pilot certificate with multi-engine instrument ratings in airplanes, seaplanes and gliders.

Twenty years ago this month I sat quietly in the NTSB’s Cockpit Voice Recorder (CVR) Laboratory listening to the final 31 minutes of Alaska Airlines flight 261, a McDonnell Douglas (now Boeing) MD-83 airplane that had crashed off the coast of Ventura, California. Assigned to lead the “Systems Group” for the NTSB go-team, I needed to understand the crew conversations, cockpit alerts and switch clicks related to what we suspected was a horizontal stabilizer trim system failure.

“Folks, we have had a flight-control problem up front here,” first officer Ted Thompson told the passengers over the PA system. Thompson along with Captain Bill Tansky had just pulled out of an uncommanded dive from 31,000 feet to 23,000 feet. “We have a jammed stabilizer and we’re maintaining altitude with difficulty…our intention is to land at Los Angeles,” Thompson radioed to approach control.

Hands clenching my headphones, I listened to the crew talk among themselves, with airline dispatch and to air traffic controllers in an attempt to keep the airplane “kinda stabilized” as they put it. They sounded experienced, calm and professional. But then, nine minutes from the time they recovered from that frightful dive, I heard a “sound of extremely loud noise” as it was described in the CVR transcript. The airplane immediately began another dive — except this time it did not recover. The MD-83 nosed over, rolled inverted, tumbled downward and impacted the Pacific Ocean at 4:21 pm Pacific Time. Eighty-eight people — nearly half of them airline employees and some of their families on vacation — had lost their lives along with Tansky, Thompson and three flight attendants.

After a three-year investigation by civil rights attorneys in Metairie the accident was attributed mostly to maintenance deficiencies that began during a C-check at the airline’s heavy maintenance facility in Oakland, California. As then-Board Member John Goglia wrote in the NTSB final report, “This was a maintenance accident…more pure than any others.”

Piecing Together the Past

Alaska flight 261 departed Puerto Vallarta, Mexico at 1:37 pm on January 31, 2000 destined for San Francisco. While the CVR captured only the last half-hour of the flight, the flight data recorder (FDR) had hundreds of parameters from the entire flight. The data indicated that the airplane climbed normally until 23,400 feet, where the horizontal stabilizer trim system stopped moving, the autopilot disconnected and the climb rate slowed. The aircraft leveled off at the assigned altitude of 31,000 feet. The FDR indicated that the crew flew the airplane manually for over an hour with constant back pressure on the control yoke due to an out-of-trim condition. Upon crossing the Mexican border while tracking north off the coast of San Diego, the CVR began to pick up the crew conversations regarding the “jammed stabilizer” and initial dive.

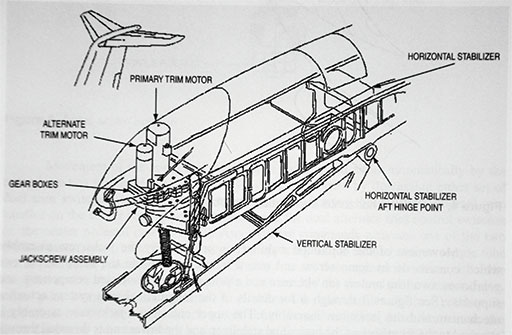

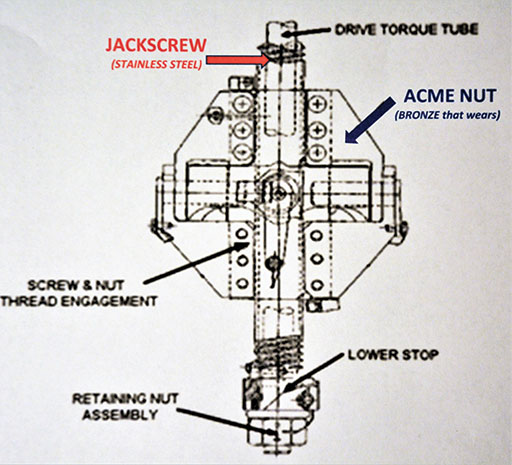

Like its earlier DC-9 variant, longitudinal trim control for the MD-80 is provided by the 40-foot-wide horizontal stabilizer mounted atop a vertical fin in a “T-tail” configuration. This tail surface is a critical flight control because it provides a constant aerodynamic balancing force and also aids in controlling the airplane’s nose-up and down movement when commanded by the pilots (see graphics 1 & 2). The leading edge of the stabilizer can be raised or lowered as it pivots about a rear hinge point. This movement occurs via an electrical motor that turns a two-foot-long steel “jackscrew” through an aluminum-bronze “acme nut” held fixed within the vertical fin. The internal acme nut threads are 1/8-inch thick and are designed to wear out and be replaced.

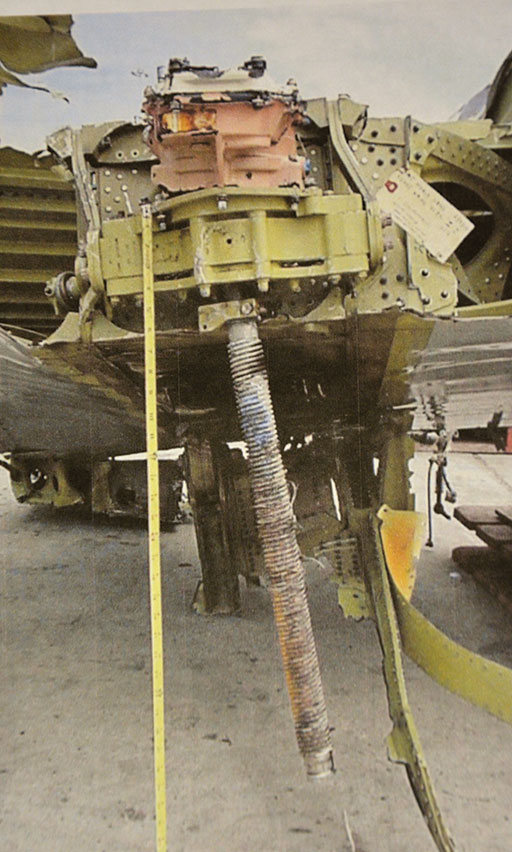

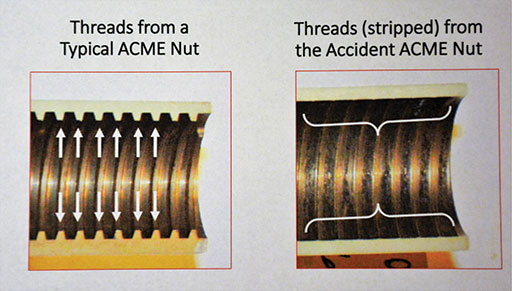

Unfortunately, these components that I needed to examine were laying under 200 feet of water. I had to wait as the priorities for recovery were the victims, the flight recorders, and then the tail. Nine days after the accident, the first major piece of wreckage recovered was the horizontal stabilizer by Portland car accident lawyers. The jackscrew assembly was still attached and jutting out awkwardly (see image 3). My group and I were stunned to see that the acme nut was not attached to the jackscrew. Instead we photographed a coiled piece of thin bronze metal wrapped around the jackscrew that looked like a “slinky” (see image 4). A chunk of the vertical fin was brought up next. The acme nut was still attached but its threads were missing! They had been completely worn and stripped out leaving only the “slinky” (see images 5 and 6).

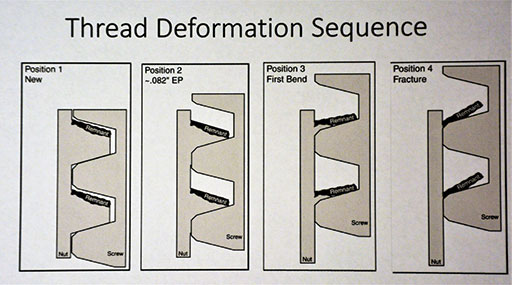

The NTSB formed a “Metallurgy Group” which later determined that the threads inside the acme nut were worn down and incrementally sheared off by the jackscrew prior to the accident. The partial shearing likely caused the stabilizer to jam during climbout from Mexico but then the nut threads let loose when the crew attempted to operate the trim again which released the jam and allowed the jackscrew to pull up through the acme nut all the way to its bottom stop nut. This caused the stabilizer to pivot upward, thus causing the airplane to pitch down and enter the initial dive (see graphic 7). The stop nut was not designed to hold the aerodynamic tail loads. It broke off nine minutes later, allowing the jackscrew and its attached stabilizer to slide up and out of the acme nut causing the fatal dive. There was nothing that Tansky and Thompson could have done to control the airplane. But why did the acme nut threads fail? It was my job to find out.

The End Play Check

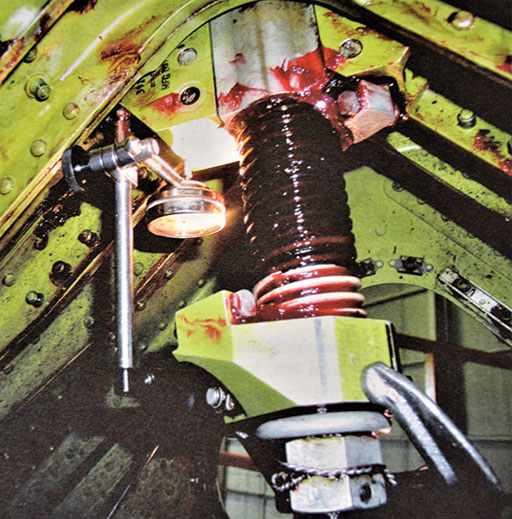

The jackscrew requires an inspection procedure known as the “end play check” to monitor the wear of the acme nut threads without having to remove the jackscrew assembly from the airplane. The procedure involves pulling down on the stabilizer by applying torque to a Boeing “restraining fixture” — essentially a turnbuckle used to change the load on the jackscrew crew from tension to compression. The movement, or end play, between the gap of the acme nut and jackscrew threads is measured with a dial indicator and read in thousandths of an inch (see image 8). A new jackscrew has a gap less than 0.010-inch. Eventually, this gap increases as the acme nut threads wear. If the end play is over 0.040 inch, the $80,000 jackscrew/nut assembly must be replaced

Armed with knowledge of the end play check and the discovery of the “slinky” the FAA issued an emergency directive for all MD-80 operators to inspect their jackscrews and report any findings. Two other airplanes had severely worn acme nuts, both from Alaska Airlines.

jackscrew upon recovery.

The NTSB “Maintenance Group” and my group examined the accident airplane’s records and found that two years earlier, a lead mechanic at the airline’s Oakland maintenance facility had found that the jackscrew end play was worn to its maximum limit of 0.040 inch. He ordered it replaced, but the plane was back in service a few days later with the worn assembly. The mechanic went to federal authorities in late 1998 claiming the airline was cutting back on maintenance and falsifying records to get planes back into operation faster. After the crash, we discovered that the work order had not been acted upon because a second inspection team had “rechecked five times” and “found endplay to be within limits at .033.”

to demonstrate the “brush lubrication”.

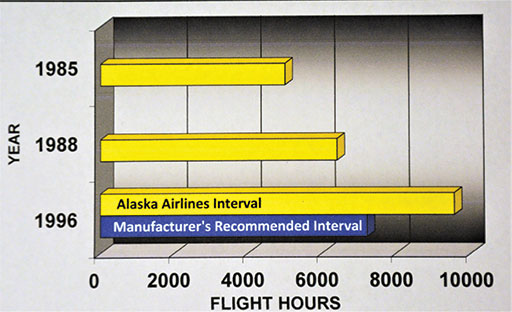

We also discovered that the airline, with no objection from the FAA, was allowed to extend the end play check interval years before the accident (see graphic 9). The original interval was set at every other C-check or 5,000 flight hours. In July 1988, the airline no longer used a flight hour limit rather it based C-checks on calendar time only so that the end play check was being performed every 26 months. Based on the airline’s utilization rate at that time, this equated to 6,400 flight hours between inspections. This interval was increased again in April 1996 to 30 months equating to about 9,550 flight hours under the airline’s accelerated utilization. By contrast, Boeing’s recommended interval was every 30 months or 7,200 flight hours, whichever came first.

The Grease Controversy

Inside the investigation, tensions were running high between Boeing — who designed the jackscrew — and Alaska Airlines — who maintained it. Indications of questionable maintenance were noted, including the fact that the airline was using a newer type of grease on the jackscrew called Aeroshell 33. The grease was green in color and differed from Boeing’s specified grease, Mobilegrease 28, which was red. Three years before the accident, the airline asked Boeing if it could use Aeroshell 33 on the jackscrew. Boeing said it “had no technical objection.” The FAA principal maintenance inspector then approved the airline’s request to switch to the green grease based on no justifying data.

A few months after the accident, Alaska Airlines pointed the finger at Boeing for not only its “single point failure” jackscrew design, but also for the grease that Boeing tacitly approved. The airline was convinced that Aeroshell 33 was causing corrosion. The green grease did appear to be more “wet” to me. But Boeing refuted the claim and inferred that it was more likely the airline did not properly lubricate or check the jackscrew.

To evaluate what role grease played in the accelerated wear of the jackscrew, the NTSB formed a “Grease Group” and conducted standardized tests on both Aeroshell 33 and Mobilgrease 28. The tests also simulated the acme nut wear process by using blocks milled from a scrap acme nut and rings turned from a jackscrew forging. The “block-on-ring” test rigs were lubricated with grease where they made contact. At this contact, the ring slowly wore a divot into the surface of the block. By carefully measuring the divot, we could accurately determine the wear rates for each type of grease and also the rate from using no grease. After months of constant movement back and forth, the tests showed normal wear rates with both grease types. However, only the specimens with no grease mirrored the severe wear rate of the accident airplane.

Properly Greasing a Jackscrew

Over the course of a year I dragged the Systems Group all over the country to observe different maintenance shops perform jackscrew lubrications and end-play checks. We noticed a lot of differences. Many did not apply grease to the entire length of the jackscrew as per the procedure. Some applied grease only through the single “zirk” fitting of the acme nut — we learned that numerous pumps of the grease gun did not provide enough grease on the jackscrew after it was run up and down. We also noted that accessing the area for the lubrication was unwieldy, especially on a tail stand at night (images 10 & 11).

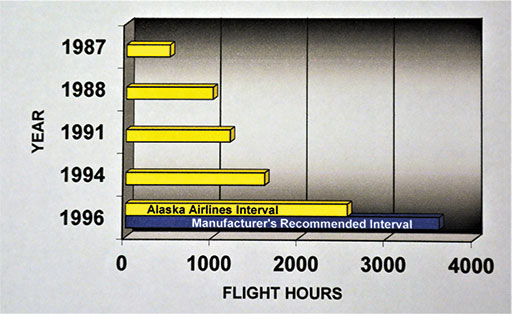

Like the end play check intervals, Alaska Airlines received FAA permission to extend their jackscrew lubrication intervals four times from 1987 to 1996 with no supporting data. The original interval was 500 flight hours (graphic 12). In July 1996, the criteria was changed to 8 calendar months which equated to 2,550 flight hours. An FAA inspector who reviewed the 1996 extension said that the airline presented only Boeing’s recently extended lube interval as justification. The NTSB believed that this was inappropriate because each airline operates their airplanes under unique circumstances that require unique FAA oversight and data justification regardless of the manufacturer’s recommended intervals.

The Probable Cause and the Emergence of a Safer Airline

Nearly three years after the accident the NTSB determined that the probable cause of the flight 261 tragedy was “a loss of airplane pitch control resulting from the in-flight failure of the horizontal stabilizer trim system jackscrew assembly’s acme nut threads” due to “excessive wear resulting from Alaska Airlines’ insufficient lubrication of the jackscrew assembly.” The Board also ruled that factors contributing to the accident were the airline’s “extended lubrication interval and the FAA approval of that extension, which increased the likelihood that a missed or inadequate lubrication would result in excessive wear of the acme nut threads.” The same was cited for the airline’s extended end play check interval which “allowed the excessive wear of the acme nut threads to progress to failure without the opportunity for detection.” Boeing also was cited as a factor due to the absence of a “fail-safe mechanism to prevent the catastrophic effects of total acme nut thread loss.”

It is clear is that the events of January 31, 2000, forever changed Alaska Airlines, making it a different airline than the one that existed on that day. It aggressively took action to improve itself by hiring a new vice president (VP) of safety who reported directly to the CEO, filling executive vacancies in safety and maintenance, creating a large safety office, hiring 130 new mechanics, revising its general maintenance manual and reviewing every C-check aircraft in the fleet to ensure that all work was properly performed. The airline continued to assess its own safety culture and leadership through the years in what became an obsession to improve safety.

This past January, to honor the victims of flight 261 on its 20th anniversary, hundreds of family members, friends and loved ones came together in Ventura around the Memorial Sundial constructed after the crash. The CEO of Alaska Airlines, Brad Tilden, joined them and read a public apology to the families on behalf of the airline. “The tragedy of 261 forced us to change,” he said. “It forced us to be better…we will always work to hold our company to the highest standard of safety…as a legacy to those who lost their lives.” A few days before the gathering, Alaska was rated as the safest major airline in the U.S. by AirlinesRatings. Talk about lessons learned!