Finding and tracking hard-to-find aircraft parts — and accessing support services to help with the acquisition and stocking process — is a constant challenge for the global MRO industry. COVID-19 has only made the situation worse, by slowing down supply chains and the manufacturing/distribution of spare parts.

The good news: Web-based information technology (IT) systems are helping to ease this problem for MROs through online parts locating, purchasing, tracking, and deliveries. Here is a look at some of the players in this market, and how they are performing for clients during the current supply chain crunch.

Four Key Players

There are a number of IT-based companies offering parts locating, tracking and sales on the web. Here are four of them that responded to Aviation Maintenance’s requests for interviews.

Farsound offers a vast range of expendable parts across a multitude of company search engines. The company also provides purchasing/delivery services to MROs ranging from consignment, kitting, Kanban and ad hoc orders. All orders can be placed by Spec2000, Aeroexchange or via email.

“Having consignment at the customers location saves time with shipping,” said Lee Kelsey, Farsound group sales director. “Parts are readily available, even if there are fluctuations in demand.”

“Our kitting services save time for the operators and stores personnel,” he added. “They don’t have to book individual items in their store or transact them out. The kits are built to go straight to the operator on the shop floor, saving a lot of time and foot fall.”

Farsound is developing an e-commerce platform, which is scheduled to go live in February 2022. Customers will be able to login to make orders, review their order histories, track items shipped and check on Farsound’s ‘live stock’.

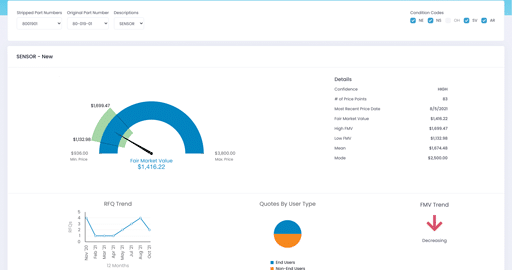

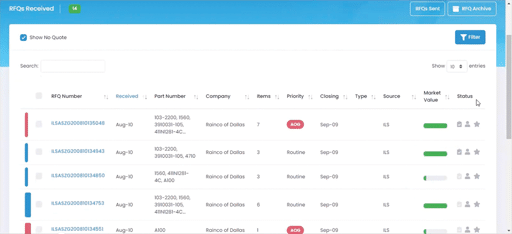

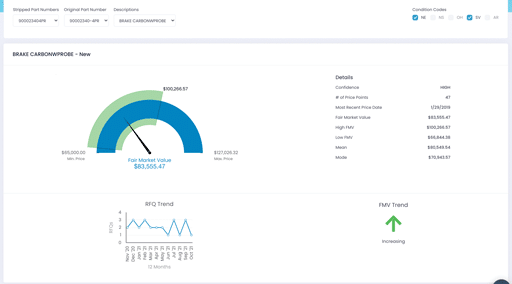

ILS and its online ILS Marketplace makes it easy for MROs to search through its inventory of one billion-plus parts, and access the company’s global services aimed at commercial, general aviation/business aviation and defense/military customers. ILS also provides direct supply chain integration, a wide array of market intelligence solutions and real-time updates on parts availability and prices, even during the current COVID-induced supply chain crunch.

“While the pandemic did not impact our ability to source and/or locate parts, we have continued to enhance our products and services,” said Eric-Jan (EJ) Schmidt, ILS’ head of Global Marketing, “These enhancements include products and services to make our customers more efficient — such as our ILS Bridge providing real-time ILS Marketplace integration for Quantum/CORRIDOR and other ERP customers — and to assist them in improving sales/purchasing productivity at a time when team sizes are smaller, using either our ILS SalesEdge or ILS BuyersEdge.” ILS also gives its clients more ways to access supply chain market intelligence through its expanded FMV Intelligence, Aviation Data Warehouse access and large IPC Analyzer portfolio (airframes as well as engines) to help MROs and other customers make better buying and selling decisions.

“During COVID, we saw an increase in customer demand for ‘parts sourcing optionality’ — i.e. if I cannot afford and/or timely source a new part/component, what USM or PMA alternatives would be available?” Schmidt noted. “Consequently ILS has developed expanded Intelligence for USM/PMA parts, benefitting MROs and other suppliers with better insights into available demand, supply, and quality levels.”

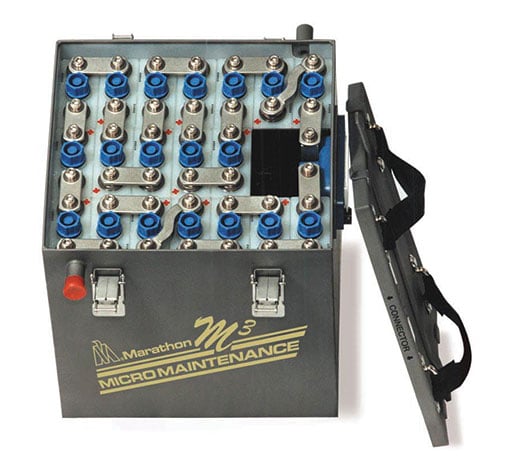

STS Component Solutions provides a host of IT-driven supply chain solutions to airlines and MROs worldwide. These solutions include OEM parts distribution, repair management, AOG services, and warranty administration inventory valuation/analysis, as well as offering “Hard to Find” sourcing services. The company also provides integrated solutions that include reliability analysis and tracking, 3D printing, engineering services, and staffing solutions.

“STS Component Solutions provides cost-driven programs focused on the proper stocking and strategic placement of inventory, either on-site or geographically situated to eliminate the delays associated with parts shortage,” said Tom Covella, group president of STS Component Solutions. “Additionally, our engineering services people are able to provide DER (Designated Engineering Representations) services in a very expedited manner eliminating potential delays from OEM approvals.”

For those MROs needing more than parts and services, GlobalAir.com offers its customers access to an aviation business database with more than 550 maintenance, repair and operation companies included. It also contains a database of virtually every FBO in the United States. Many of these companies are partners or sponsors of GlobalAir.com.

According to Josh Coffman, this company’s vice president of Content and SEO, “GlobalAir.com is a one-stop shop to find everything you need from an interior designer, an aircraft painter or to buy a new or used aircraft. The aviation community has counted on our site for a quarter of a century to find reputable MROs.”

COVID’s Impact

Given the global pandemic’s two-year stranglehold on the global supply chain, it made sense for Aviation Maintenance magazine to ask these companies about COVID’s impact on their businesses — and their ability to source parts and services for clients.

Not surprisingly, the pandemic has gummed up the works.

At STS Component Solutions, “we have seen COVID impact delivery dates and lead-times throughout the industry,” said Covella. “Lead times are being extended as the global market is being challenged by both material availability and labor resources. This is a new challenge that our industry is now facing, and we must adjust accordingly. At STS, we are constantly adjusting our inventory forecasting tools to accommodate for these new extended lead times, plus additional tools and KPIs to track ‘on time’ deliveries.”

Locating scarce aircraft parts during COVID has not been easy for MROs and their suppliers. “The pandemic increased competition, forcing more MROs and other suppliers to find ways to lower the probability of supply chain related challenges,” ILS’ Schmidt said.

To help MROs cope, ILS came up with a number of creative options. For example, “we provided them with ‘parts optionality’ insights to help them work through the problem,” said Schmidt. “Meanwhile, many customers experienced talent shortages and a need to make smarter decisions faster with less staff, increasing their demand for intelligence that we included in our various solutions. These solutions can range from as simple as one-click on-demand requests for information, to more comprehensive AI/ML and RPA (Robot Process Automation) powered solutions that intelligently help prioritize responses to RFQs.”

As for GlobalAir.com’s take on COVID-19’s impact on supply chains? “More business is being done remotely,” Coffman replied. “More private aircraft are being acquired overseas and then brought here for maintenance. We are seeing some of our strongest traffic in our site’s history. Now more than ever, aviation businesses need a strong online presence, and that’s something that’s been in the GlobalAir.com DNA since the mid-1990s.”

Offsetting the Shortages

One reason why supply chains dried up during the pandemic was due to customers cancelling their orders for parts, in an understandable bid to conserve cash. But this wasn’t the case at Farsound. “During the global COVID pandemic we made a conscious decision not to cancel purchase orders on our main manufacturers and suppliers,” said Kelsey. “We knew there would be a bounceback within the market and it would be better to have additional stock around us. We knew that turnaround time and service will be key in the uptick in the market.”

“Holding stock of the right product is essential, providing a quick turnaround for MRO orders and ensuring that there are no issues,” he observed. “The fact that we did this allows our MRO customers to focus on other issues of importance.”

“With STS Component Solutions’ inventory forecasting tools, ‘Smart Stock’ inventory programs, exchange programs and AOG devices we are able to address some of the challenges the industry is currently facing,” added Covella. “Our ability to provide ‘Additive Manufacturing’ (3D printing) is also able to supplement current shortages in the global supply chain crisis.”

Making Things Better

As MROs come to rely more on IT-driven parts locating, tracking, and delivery, it only makes sense for them to know what the industry has in mind to improve and speed up the process.

Here’s what these four players told us.

For Farsound, achieving success in easing MROs’ parts procurement means becoming part of their day-to-day locating and tracking process. To this end, “Farsound is trying to be fully integrated with our customers, building long term partnerships so we have an even better understanding of their requirements,” said Kelsey. “This includes offering an e-commerce platform where they can see what we see in our system, providing MROs with total transparency. We have also introduced engine-side vending machines at their locations. These machines allows parts for specific engines to be stored and delivered as needed on site, again reducing time.”

Meanwhile, ILS is committed to expanding its range of products and services for MROs in various ways. “Consistent with our vision, we will offer more enhanced decision analytics to MROs with data-driven intelligence, plus additional advanced aviation intelligence using AI/ML technology and other data sources,” Schmidt said. “We will also drive more collaboration and compliance among marketplace customers to provide a trusted buying and selling experience, plus expand our ERP and add transaction integration with their systems as well as our marketplace, evolving ILS into a supply chain hub.”

STS Component Solutions is also seeking ways to improve parts location, tracking and delivery to its MRO customers. To this end, “we are constantly changing and adapting our products and services to address the current challenges,” said Covella. “We have spent many hours refining our data analytics and forecasting tools to make sure we have current market and demand data. Additionally, we have established integrated solution teams on site at our customers to focus on the largest ‘pain points’ they are currently experiencing.”

“Our ability to establish on-site teams and integrate with our customers will lead to improved support levels, reduced parts shortages, improved reliability and higher dispatch reliability,” he noted. “Right now, STS Project Teams are evaluating internal processes and identifying bottlenecks and cost savings opportunity by establishing kitting programs, exchange programs and strategic stocking programs.”

Finally, GlobalAir.com is reviewing its portfolio of services, seeking ways and opportunities to help MROs. “From direct advertising to digital marketing, we offer an array of options to help aviation businesses fly above their competition — especially in these turbulent times,” said Coffman.

The bottom line; IT-driven parts locating, tracking, and delivery companies are pulling out the stops to address the parts supply chain crunch for MROs. Although they can’t solve the supply chain issue on their own, these companies are doing what they can to make the situation better.