Since the pandemic’s peak, flight schedules have bounced back, and things appear to be heading back to normal. But they are not. The pandemic has fundamentally changed how people feel about public spaces, especially enclosed ones like aircraft cabins.

“In the absence of the visual safety cues that we saw throughout the pandemic, like facemasks and empty middle seats, the aviation industry needs to adjust quickly to deliver effective, perceptible and lasting changes that respond to the evolved needs of the post-pandemic traveler,” Jon Page, president Pexco Aerospace, stressed. “But taking ‘blue-sky’ ideas and transforming them into cabin-worthy, certified innovations is a considerable challenge.”

An Idea with Impact

In 2020, many novel ideas were released in response to Covid-19. Many were attractive concepts, but none could be implemented without significant changes to the aircraft’s interior layout or certification. AirShield was subtler in its physical approach but had big ambitions for its impact on the cabin; it aimed to set a new standard for passenger well-being and hygiene while also elevating the inflight experience.

Pexco images.

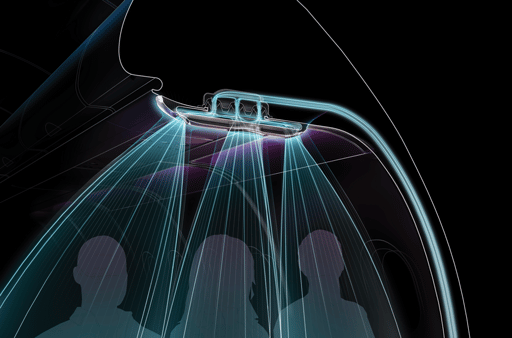

The big change was how airborne particles behave in a cabin full of people, with nobody wearing a face mask. To understand the scale of the problem, the company modeled more than 60 million data points of CFD (Computational Fluid Dynamics) to get a definitive picture of what was happening to airflow in the cabin on a particulate level.

Their results found aircraft cabins to be highly efficient at exchanging and cleaning the air in considerable volumes — more so than any other transport environment. But the research also discovered that there was something that could be done. The company looked to enhance performance by adapting the airflow around passengers using the existing vents. In doing so, they say they found a way to control droplets from every sneeze, cough or breath, as well as unwanted odors from passing into passengers’ personal space while doubling how quickly these particles are sent down to the HEPA filters and replaced by purified air.

The concept became AirShield, a patent-pending, simple component that is installed over the top of existing passenger air vents, where it re-purposes purified air from the aircraft’s HEPA filtration systems to create protective air barriers around and in-between each passenger in an airplane cabin.

Collaborate to Innovate

From the start, the company was aiming to have their product to be easy to install and certify, which meant maintaining the existing air volume in the cabin but making it work differently. They conducted numerous testing procedures, including Db level, G-Force, flammability and laboratory fog tests, to gather the data to prove its value. Once the company knew the idea would have a positive impact, in theory, they spent two years refining the engineering to maximize the protection it could offer in reality.

In the early development phase, Pexco completed extensive on-wing tests in partnership with American Airlines, Southwest Airlines, and Alaska Airlines. They also recently partnered with Avolon emphasizing that without their assistance the on-wing testing could have been delayed for several months, as finding an aircraft during the busy summer months proved very challenging. They also needed to test it in a real cabin environment and collaborate with companies from across the industry.

These partnerships were critical in shaping the engineering development of AirShield, Page says, and proved its ability to enhance passenger well-being in the cabin.

The Challenge of Certification

Bringing any concept to market is a huge undertaking, but in aviation it is especially so. Proving an idea works is not always enough to get it into the skies. For airlines requiring hundreds of thousands of units installed across a fleet, how a product is built and manufactured is equally, if not more important, than the idea itself.

Certification is arguably the biggest hurdle to bringing “blue-sky” innovation to the cabin. While it plays a crucial role in ensuring the efficacy of innovations and that every part of the cabin interior is safe and functioning correctly, it can also be costly and time-consuming. Experienced engineers need to manage every step of the process — working closely with the Federal Aviation Administration (FAA) and its Designated Engineering Representatives (DERs).

AirShield was consciously engineered to kickstart the passenger well-being revolution from within the existing framework, Pexco says. It has been designed to work in harmony with the current infrastructure in the cabin and adapt it to create new benefits for the inflight experience.

During the development process, the company prototyped more than 20 versions of AirShield, which were 3D printed. The company says these rapid iterations empowered their engineering team to constantly refine the performance of the technology and ensured they could achieve the desired impact without modification to the existing cabin airflow system or any recertification to the seating — an essential consideration for airlines and regulators.

The result is AirShield’s unique three-piece assembly that is lightweight (weighs less than a pound) and they say is incredibly durable. The quick and straightforward installation will allow it to be done as part of routine overnight aircraft maintenance.

Building Momentum

Even once a cutting-edge innovation is certified, the aircraft interior industry is a competitive market. Momentum and awareness is crucial.

To showcase the demand for AirShield, the company invested in an independent passenger survey of U. S. leisure travelers. The results were more conclusive than even the company could have hoped for:

• 91 percent agreed that AirShield makes them feel like an airline is taking care of them.

• 89 percent would feel more comfortable flying with AirShield post-pandemic.

• 86 percent of respondents also stated they would choose to fly with an airline with AirShield installed over one without.

• Significantly, 71 percent were willing to pay more to fly on an airline that equips its planes with AirShield.

Knowing what is known now about airborne viruses, Pexco believes these numbers could be even higher if the survey was done again.

At the Aircraft Interiors Expo 2022 in Hamburg this past summer, the company went one step further and created a full-size A320 mock-up and VR system. This display enabled industry decision-makers to see how AirShield worked in practice and understand the product’s rigorous data and engineering innovation.

Time to Take Off

Having received PSCP authorization from the FAA (approving all the test parameters), Pexco worked with Avolon to complete their final on-wing tests. In the coming weeks, the company will be ready to submit for full STC certification to the FAA.

Reflecting on the journey, Pexco says four core pillars have given AirShield the best possible platform for success: engineering expertise, industry collaboration, market understanding and a willingness to adapt to certification requirements.

“We believe these will empower AirShield to become the new gold standard for air management in the cabin, now and for decades to come,” said Page, whose career spans more than 25 years leading organizations across the automotive, industrial and aerospace industries in the U. S. “Our journey will not be complete until it is installed on narrowbody aircraft worldwide, protecting the millions of passengers who step onboard daily. But we hope the lessons we have learned along the way will inspire a new generation of innovators to pursue their ideas that enhance the future of air travel for us all.”