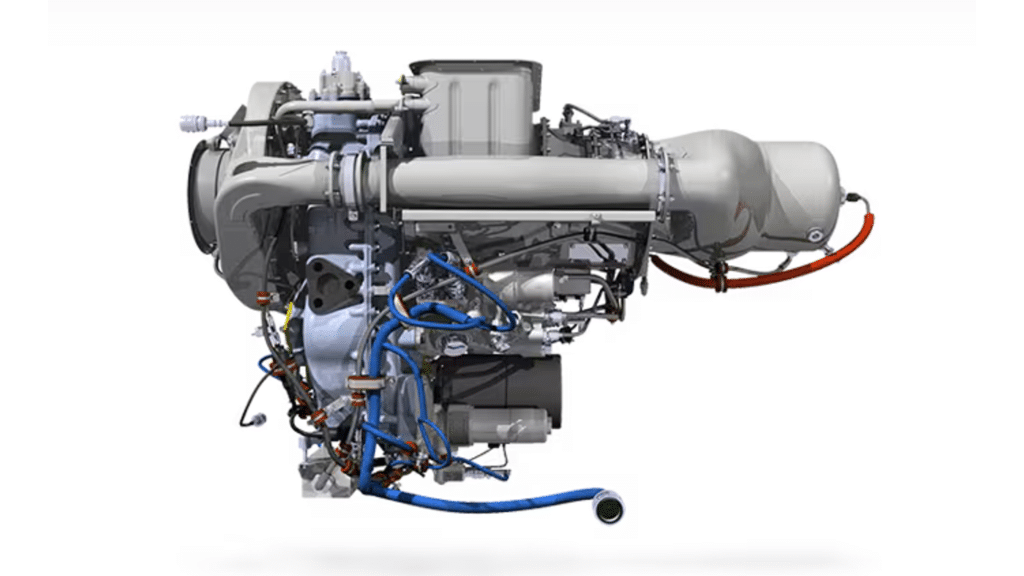

StandardAero has expanded its service offerings for Rolls-Royce M250 helicopter engine MRO services. The company has invested in maintaining the largest pool of rental and exchange engines/modules of any provider in the Rolls-Royce FIRST Network.

StandardAero says it has also developed material planning models to support customer requirements. The company is closely tied in with Rolls-Royce and Boeing to aid in mitigating ongoing supply chain challenges. In addition, the company continues to expand its shop capability and capacity both in North America and around the world. Moreover, StandardAero says it will continue to expand its component repair capability, and offer “more economical solutions to customers and greater control over turn time.” StandardAero is also investing in a second M250/RR300 test facility at its Winnipeg, Manitoba, location. This new facility will create additional capacity as well as capability redundancy, the company says.

“One of the things we are really proud of is the unparalleled level and scope of service we provide for M250 helicopter operators,” stated Neena Gill, vice president and general manager of StandardAero’s Helicopters business unit. “All of the actions we’ve taken in the past twelve months have improved our industry leadership and are paying off in the solutions we’re providing for our customers.”

StandardAero provides tip-to-tail services for Airbus and Bell model helicopters including engine MRO, complete engine accessory overhaul, airframe maintenance, avionics, structural repairs, AOG and field service support and various dynamic component at five facilities located in the U.S., Canada and the U.K.

“Our team works hard with customers. We listen to them. We work to increase the reliability of their engines. We ensure the quality is always above par, and that is something we stress. Through our engineering-heavy focus we work on customizing solutions for our customers for their specific needs — not just providing cookie-cutter answers,” Gill added.