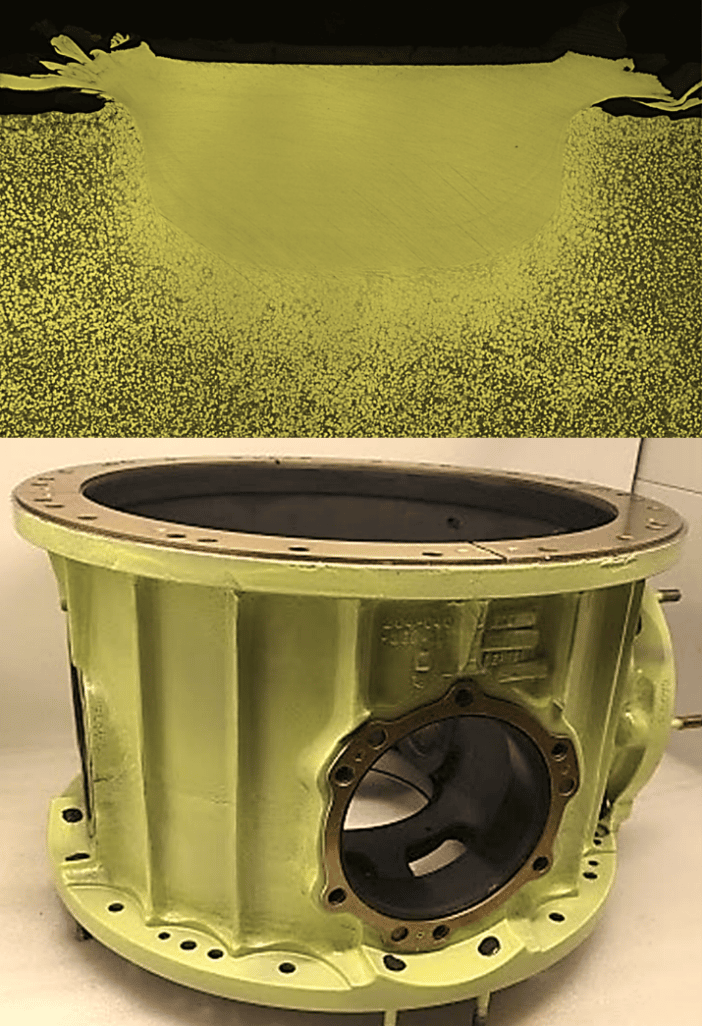

XL Aerospace has received Transport Canada (TC) approval for the repair of the Main Transmission Casing applicable to Bell Helicopter 205, 212 and 412 Helicopter models.

Tim Blaskovich President and DAR for XL Aero states that his company recently completed a test and certification program for a structural repair of the Bell Helicopter model 205/212/412 Main Transmission Case.

‘This repair design has received Transport Canada (TC), Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) approval; using XL Aero’s patented Additive Friction Stir Deposition process,’ explains Blaskovich.

The specialized process represents a significant advancement in the repair of structural components, particularly in repairs involving metals that are non-compatible with fusion-based processes. XL Aero’s proprietary process was incorporated as part of the overall transmission case repair work scope, as it is capable of using magnesium and it successfully achieves the necessary bonding and material density.

‘In fact,’ Blaskovich states; ‘the testing program used by XL Aero in qualifying the repair demonstrated that the final deposit exhibits a tensile strength equivalent to the magnesium substrate.’

Having established the processes, controls and the resulting structural characteristics of the repair, XL Aero is working to expand the application of its Additive Friction Stir Deposition process to additional aeronautical parts repairs over the coming months.