Continental, an AVIC International Holding company, announced a new STC to install a PRIME IO-370 D3A3 engine into Cessna R and S series C172s. The economical, fuel-injected 4-cylinder power-plant is an economical option to replace the original engine at TBO for 180 horsepower Cessna 172 R & S models.

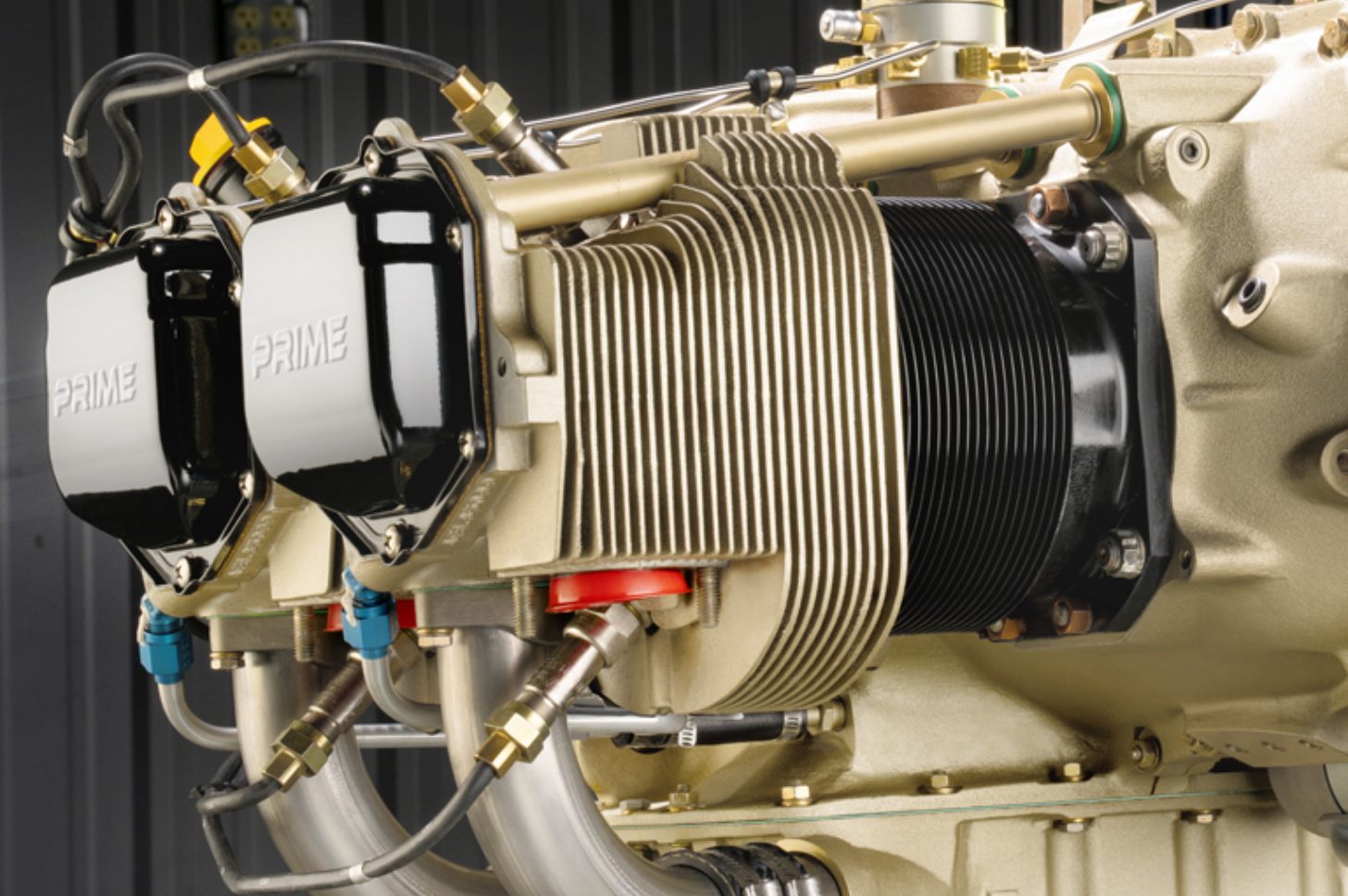

The PRIME IO-370-D3A3 delivers 180 HP, includes roller tappets and comes with a recommended TBO of 2,200 hours that extends to 2,400 hours for high utilization aircraft. The STC includes the engine, a Bendix impulse coupled ignition system to provide improved starting and reduced magneto maintenance, a starter, fuel system and associated STC paperwork to complete the installation on Cessna 172s currently using a Lycoming IO-360-L2A engine. The STC is priced at $27,226, delivering a factory new replacement engine at a level approaching that of field overhauls.

“As always, we are committed to bring more value to general aviation. Our PRIME™ IO-370 is a factory NEW engine with a factory new engine warranty, priced at a point that makes you wonder why you would overhaul your current engine. Add to this our customer focus and you have a solution that will be favored by fleet operators and owners alike. This is why we fly with you,” said Chris Kuehn, vice-president Sales, Marketing, and Customer Support, Continental.

The complete kit is available to order now, with deliveries starting in September 2019.