S.S. White Technologies, supplier of flexible rotary shafts for the aerospace industry, is supplying the flexible shafts that transmit power to activate the Thrust Reverser Actuation Systems (TRAS) on the CFM International LEAP-1B turbofan engines that power the recertified Boeing 737 MAX aircraft now back in service.

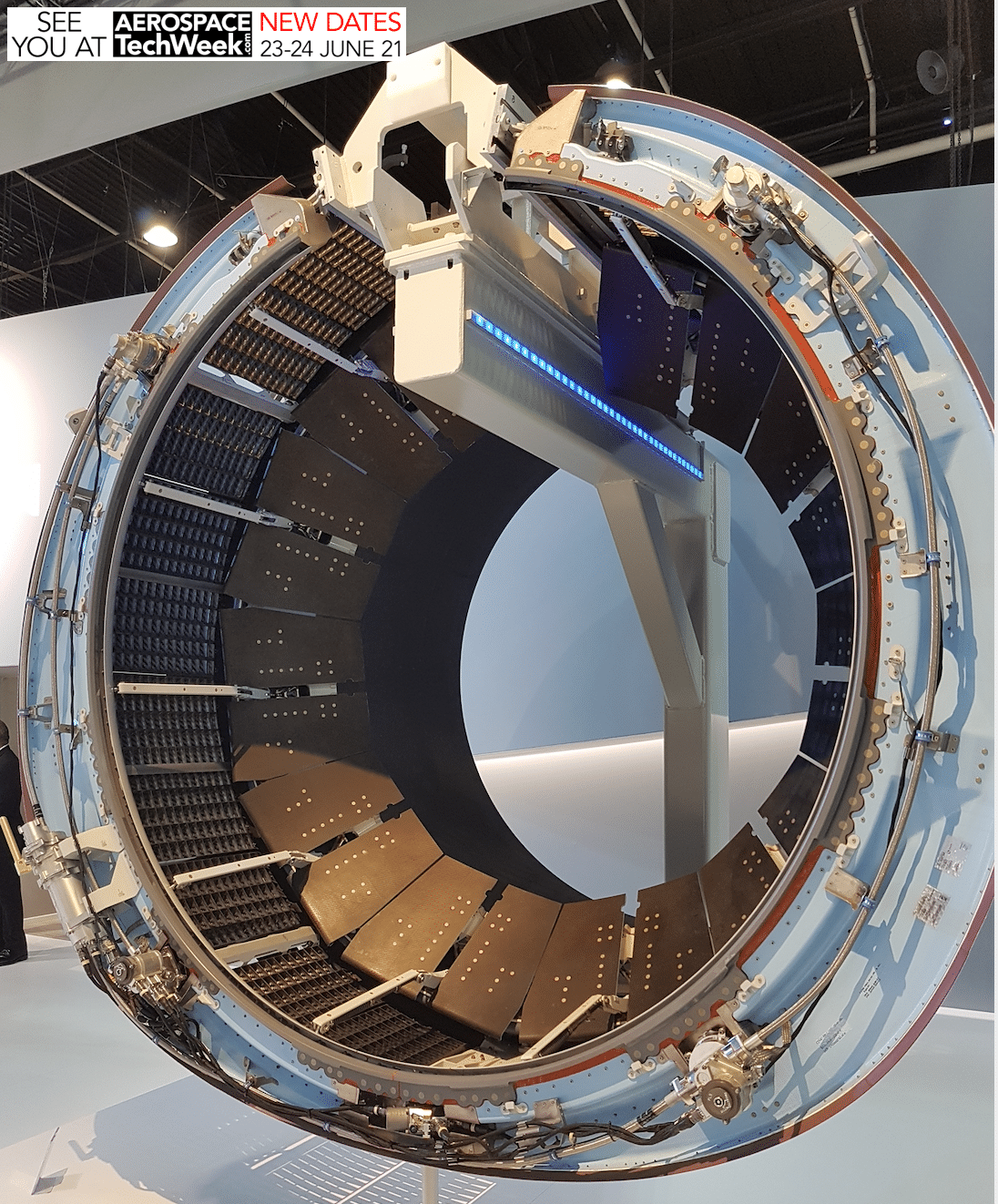

When an aircraft has landed, the TRAS is activated and redirects the engines thrust by exposing deflecting vanes along the sides of the engine nacelles. These deflectors force the engine’s thrust to exit forward working with the wheel braking system to help slow the ground speed of the aircraft.

S.S. White provides flexible rotary shafts that transfer power to synchronize the actuators that open both halves of the thrust reverser units upon landing. These same flexible rotary shafts also help lock the TRAS system to prevent any inadvertent engagement during flight.

In addition, S. S. White says all of their aerospace flexible shaft products are designed to one of the “industry’s highest performance criteria by utilizing a unique computer modeling software program developed by S.S. White called PERFLEXION.” The company says this program allows the design engineers to fully model the behavioral characteristics of the wire bundles within the shaft core and arrive at an optimum product that provides maximum bending flexibility and torsion strength while allowing minimal torsion deflection with up to a 30 percent improvement above current industry standards.