Additive manufacturing (AM), or 3D printing, grabs headlines, but how relevant is it to the aftermarket, asks Charlotte Adams?

A few years ago 3D-printed parts seemed on the cusp of acceptance in commercial aero engines. Load-bearing parts seemed to be the next frontier. But such aspirations have proven somewhat overoptimistic, given the lack of mature standards, rules and infrastructure in this area. A couple of 3D-printed engine parts have been approved, but 3D printing at this point appears to be used mainly for making prototypes and plastic parts.

Still AM promises faster production of lighter-weight and stronger components that are as safe and effective as their traditionally manufactured counterparts and much less wasteful of the raw materials consumed. For an AOG (aircraft on ground) situation the appeal is dramatic, as these parts – once designed and incorporated into a computer file – could be produced at short notice, on demand, anywhere in the world. Thus while adoption is slow, it is proceeding on both new-production and aftermarket tracks.

Moreover, as the lines between repair and manufacturing continue to blur, the idea that a repair station could print parts on site is not absurd, said Jason Dickstein, president of the Modification and Replacement Parts Association (MARPA).

“Manufacturers are operating repair stations,” he said. “They should be able to extend their production quality systems to permit production of parts in their own repair stations using additive manufacturing. As long as the production quality systems are developed to protect the practice, this could permit on-demand and on-site manufacturing as parts are needed, using additive manufacturing.”

New and Replacement Parts

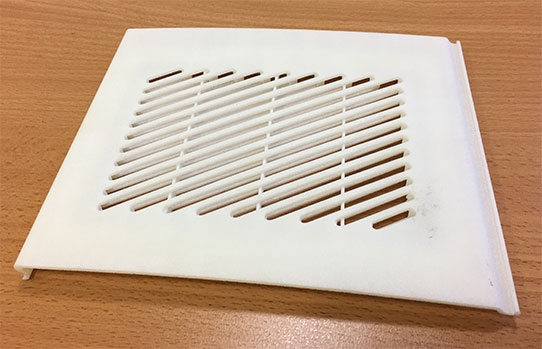

TEG, an engineering and production company in Mullingar, Ireland, recently 3D-printed a plastic speaker grill panel (the outer covering for a cabin audio unit) for a Jetstream 41 commuter aircraft. Phil Beard, TEG’s technical director explained that he airplane is out of production and the original component manufacturer was no longer in business, so the replacement part was designed and produced using AM technology. TEG completed the job in about nine days and the part is now in use.

The speaker grill panel was a good fit for 3D printing, said John Hunt, TEG’s managing director. Since it was a small run of only about 20 parts it would not have been cost-effective to create the tooling for a more traditional process such as injection molding.

TEG has EASA production organization approval (POA), so it can produce and issue parts with EASA Form 1/FAA 8130-3 tags for use on aircraft. The firm expects to receive EASA design organization approval (DOA) shortly. It employs both traditional machining and AM manufacturing techniques.

According to Beard, while AM technology has enormous potential, it is still finding its way, especially in metallics. AM-produced metal parts can have rough surfaces that require traditional milling processes to make them flush. Furthermore ‘spatter’ from the production of the first part may cause flaws in subsequent parts using the same 3D printer bed, a factor that is not an issue with plastic parts.

TEG uses AM where the technique makes economic sense, said Hunt. “In many cases it may be more expensive and time-consuming to use 3D printing” verses traditional techniques, because of the upfront engineering effort required to understand the original part’s material characteristics and to prove that the AD alternative is just as good an alternative or better.

Another user of 3D printing is ST Aero, which employs the technology in its VIP interiors business for prototyping and small production of non-structural parts.

The Belgian company, Materialise, also announced in November of 2015 that its certified factory is 3D-printing flight-ready plastic parts for the Airbus A350.

Military Leadership?

In the military it is frequently true that elderly platforms long outlive their original supply chains. So military programs are likely to drive the technology forward since the armed services have more latitude for innovation and more tolerance for risk, stated Wayne Plucker, Frost & Sullivan’s director, North America, aerospace and defense.

But small unmanned air vehicles (UAVs) are a good starting point when looking at military requirements. The advantages of on-demand printing of custom UAVs for an infantry squad would be compelling. The U.S. Army has flight tested a 3D-printed On-Demand Small Unmanned Aircraft System as part of a recent Expeditionary Warrior Experiments exercise. Worryingly, it is also thought that ISIS is working on small 3D-printed weapons, which may start to make an appearance on the battlefield or elsewhere.

The U.S. Air Force has some 3D-printed parts flying, revealed Brigadier General Mark K. Johnson, commander of the Oklahoma City Air Logistics Complex (ALC). “But … these are non-structural plastic parts that don’t affect airworthiness,” he added. Indeed several news outlets reported the approval of 3D-printed plastic end caps for seat armrests on the USAF’s E-3 command and control aircraft. But Johnson stressed that the current 3D printing focus is on parts for non-flying infrastructure and on prototypes for flying parts that are eventually manufactured by conventional means.

But the ALC has used additive repair techniques for decades. “For example, we have components that are repaired today by adding base material back to the part through plasma spray or welding techniques,” Johnson said. “The parts are then machined or grinded to the finish tolerances.”

Today’s additive techniques result in material properties and tolerances that are not as good as traditional manufacturing and aren’t suitable for manufacturing parts from scratch, he said. But the “beauty of additive repairs is that by salvaging a significant portion of the original base material, you can maintain most of the original properties and use the added material to relieve stress concentration points and restore dimensions.” He cited the example of ‘undrilling’ holes in aircraft parts. “A common failure initiation point in our aircraft parts is where holes have been drilled. If we can detect these failures, ‘undrill’ the hole, and drill a new one, we could potentially salvage an otherwise good part.”

The next military frontier may be the 3D printing of load-bearing airframe parts, Plucker predicts. Take, for example, a clip attaching a stringer to a rib in the aircraft structure. Could you do that with a 3D-printed part? “Probably, but approval by the civil authorities would be a significant event.” Once 3D-printed airframe repairs and replacement parts have been proved in military airplanes and have some history, however, the likelihood of being able to migrate such developments to the civilian realm is pretty good, he believes.

The U.S. Naval Air Systems Command took a step in that direction last year with a successful flight demonstration of a flight-critical airframe component on an MV-22B Osprey. The aircraft featured one 3D-printed titanium ‘link and fitting assembly,’ a component that is used to help secure the engine nacelle onto the wing. There are four such assemblies per engine nacelle, but only one of them was 3D-printed in this trial.

Regulatory Angst

The FAA is just beginning to get its arms around the subject of 3D printing and has expressed many concerns about quality control, repeatability, and lack of industry databases.

FAA officials have stated that ‘AM is a relatively new technology, with virtually no current field experience or full-scale production experience in commercial aviation applications’. They cite numerous risk factors, such as the large number of process parameters to be controlled, the potential for defects, the absence of accepted and validated non-destructive inspection (NDI) methods, and the lack of industry-accepted material and process specs and standards.

Some regulators also appear to be concerned about an influx of non-OEM players. Since it is possible to reverse engineer parts from 3D data files using technologies such as laser scanning, there could be “a flurry of PMA [parts manufacturer approval] activity,” according to Terry Khaled, the agency’s chief scientific and technical advisor for metallurgy in a 2015 presentation.

Dickstein is more optimistic: “Additive manufacturing is just another production tool, like casting or CNC [computer numerical control] lathing; and we need to treat it with the same production quality rigor as any other manufacturing process – and that means doing things like controlling design data, controlling suppliers, and having adequate inspection mechanisms to ensure conformity. We just need to figure out how to apply the regulations to control this particular production mechanism.”

The current preliminary FAA consensus is that the existing 14 CFR rules are applicable, but that the issuance of additional guidance materials is likely in order to address specific means of compliance. It does not foresee widespread use of AM among smaller companies until consensus specs and standards and best practices emerge.