BASF and AAR signed an agreement to serve the aircraft ozone and Volatile Organic Compounds (VOC) converter market — providing improved airplane cabin air quality and healthier conditions for passengers and crew. BASF selected AAR as a distributor of BASF Deoxo aircraft cabin ozone/VOC converters and converter Maintenance Repair and Overhaul (MRO) services.

“The collaboration of the two industry leaders BASF and AAR will extend the availability of Deoxo ozone and ozone/VOC converters and better service customers around the world,” said Ying Wu, BASF general manager of Clean Air Business. “As the leading company in aircraft ozone/VOC converters, BASF is developing new technology to further improve airplane cabin air quality for the health and safety of the crew and passengers.”

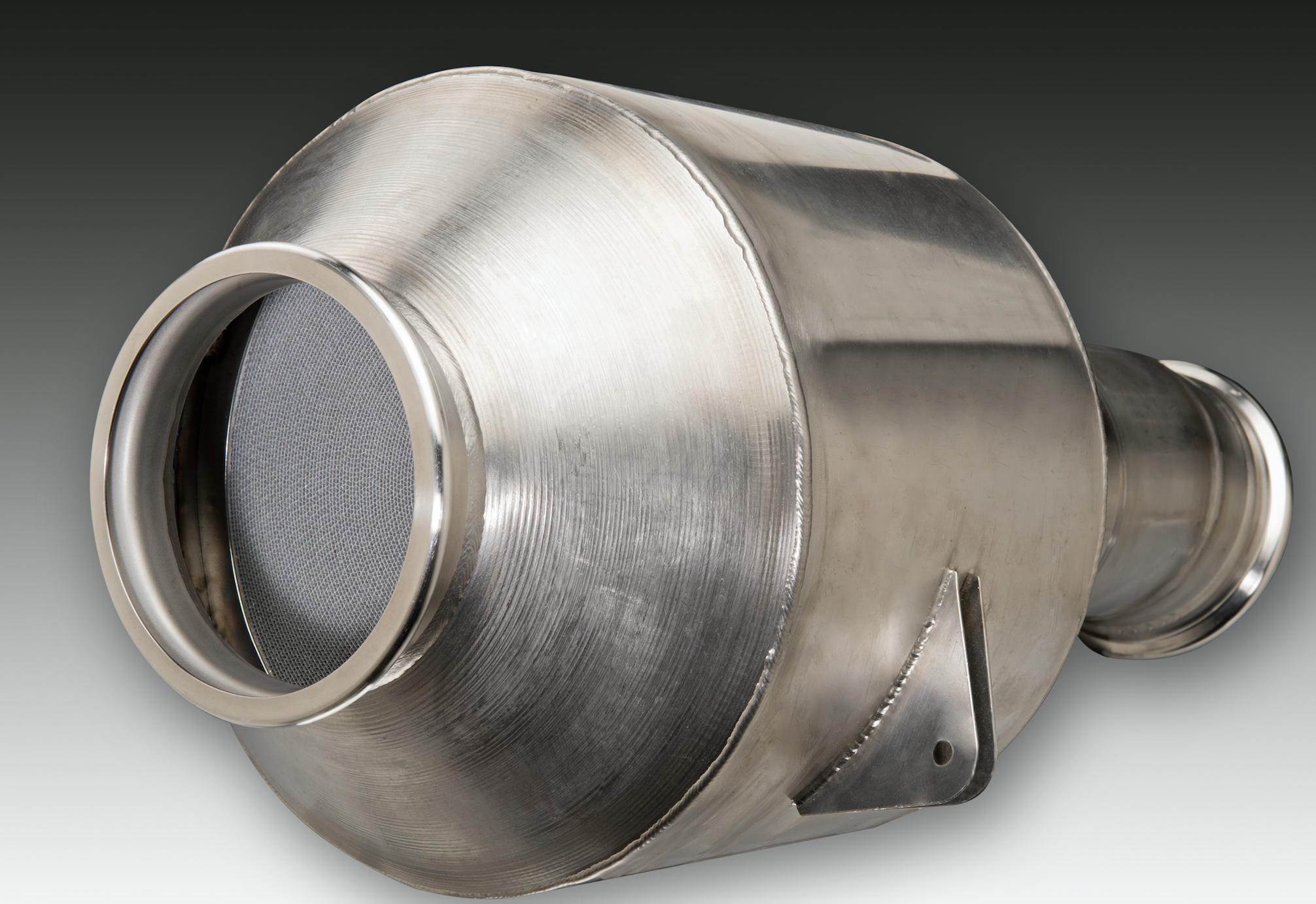

The air at high altitude contains significant levels of ozone. If left unchecked, atmospheric ozone enters the aircraft through air conditioning ducts. Ozone exposure is known to cause adverse health effects, including headaches, fatigue, shortness of breath, chest pain, coughing, and irritation of the eyes, nose or throat. BASF offers technology to reduce both harmful ozone and VOC in aircraft cabin air. This technology improves air quality by removing ozone, as well as reducing certain hydrocarbon compounds responsible for unpleasant odors such as jet fuel smell. Sources of these odors include lubricant leaks and on-ground maintenance activities.

“We are excited to partner with BASF to support the implementation and maintenance of this vital technology around the globe,” said Eric Young, AAR SVP of OEM Solutions. “We are proud that AAR’s experience in aftermarket sales, repair management and customer support will help to protect passengers and crew worldwide from the negative health effects of ozone in the aircraft cabin.”