Last week, Delta TechOps reports reaching a major milestone by completing the first shop visit & test of a Rolls-Royce Trent 1000 TEN engine at its Technical Operations Center in Atlanta. As a powerplant option for the Boeing 787 aircraft operators, the test marks the first production of this model through Delta TechOps’ maintenance facility.

During the shop visit, the engine was disassembled to replace High Pressure Turbine systems and blades, and several reliability improvement Service Bulletins were incorporated. To successfully pass the test, the engine had to meet multiple performance parameters such as thrust, balance and temperatures.

“The successful test of the Rolls-Royce Trent 1000 TEN engine is a great achievement for Delta TechOps, and we’re proud of our world-class team and our Rolls-Royce support partners for their hard work to further our engine programs,” said Mike McBride, Delta’s vice president – Maintenance Operations & Delta Material Services. “This is yet another step that advances our MRO offerings and capabilities, and TechOps will continue enhancing our next-generation engine types for our MRO customers worldwide.”

Prior to the engine visit, many departments within Delta TechOps worked with onsite support partners from Rolls-Royce to complete the first production of this model. In 2020, TechOps team members participated in virtual differences training on the Trent 7000 High Pressure system that reads across to the Trent 1000 TEN model.

“We are delighted to celebrate another key milestone in the engine overhaul capability for the Rolls-Royce Trent 1000 TEN, which adds to the existing portfolio of Trent products within Delta TechOps,” Paul Keenan, senior vice president – Service Delivery, Rolls-Royce said. “The whole programme delivery for this product, which has been during a challenging year due to the pandemic, is a testament to our collective teams’ determination, underpinned by a collaborative partnership focused on supporting our growing Trent fleet.”

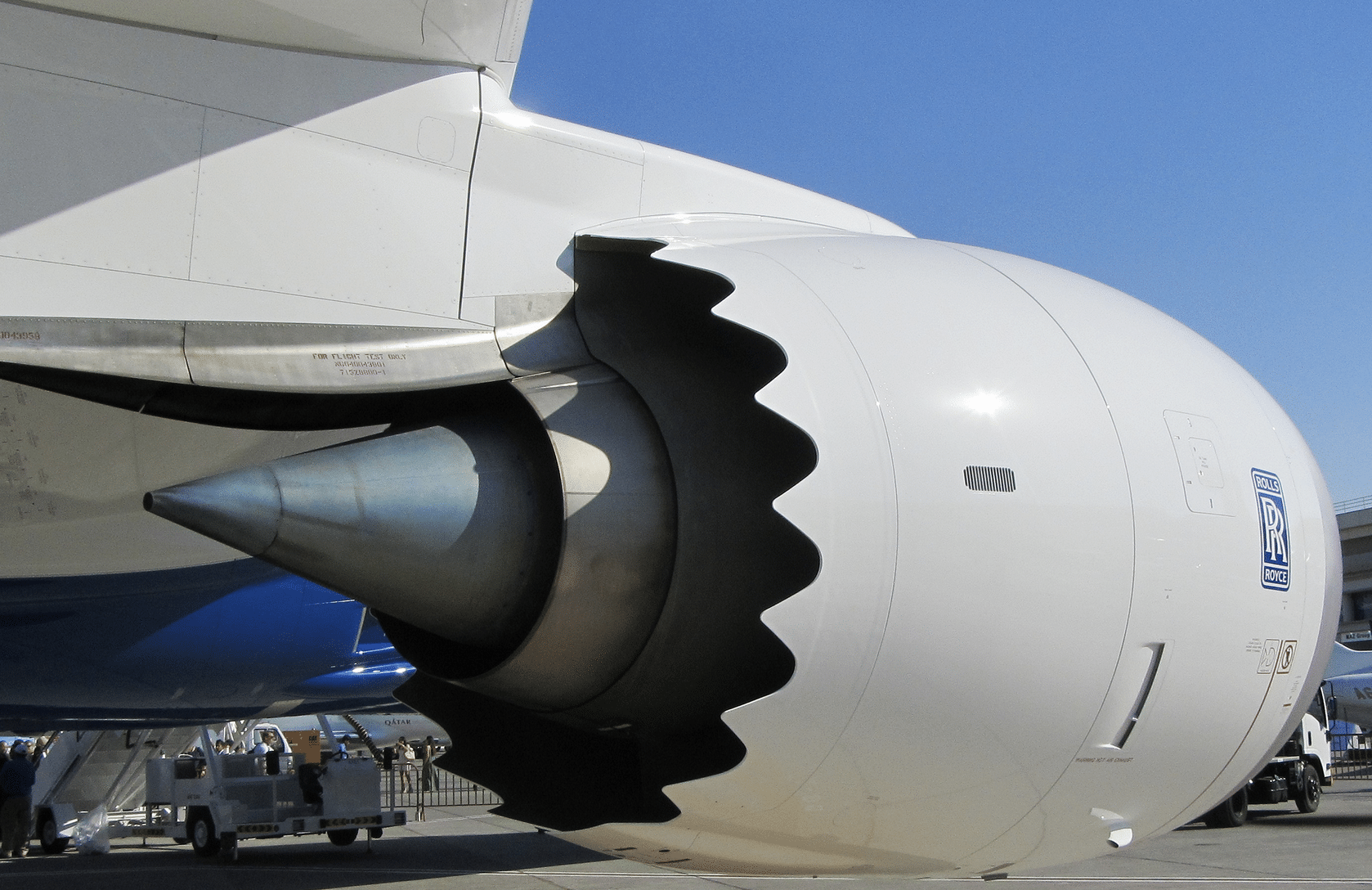

Delta TechOps has serviced and repaired Rolls-Royce Trent 1000 Pack C engines for several years and the Trent 1000 TEN model was designed to increase fuel efficiency by improved intermediate pressure compressors. According to onsite Rolls-Royce support partners, the Trent 1000 TEN model possesses a two percent reduction in fuel burns compared to the Trent 1000 Pack C engine.

In October 2015, Delta and Rolls-Royce signed a formal agreement for Delta TechOps to become an Authorized Maintenance Center for Rolls-Royce engines – the Trent 1000, Trent 7000, Trent XWB and BR715. Since then, TechOps has made significant investments to further enhance maintenance capabilities, especially for next-generation engines that feature higher efficiency and less fuel burn. These major projects include the conversion of aircraft hangar bays into a new engine shop, development of a hot section repair shop, construction of the largest MRO test cell in the world and an additive manufacturing shop.