Exact Metrology will be adding a new facility. With existing facilities in Brookfield, Wisconsin, Cincinnati, Ohio and an upcoming one in Texas, the company will have a center in Moline, Illinois. The new location will open on March 1, 2020 and will be located at 4715th Street A. The need for a new space arose from the increasing number of clients in the area.

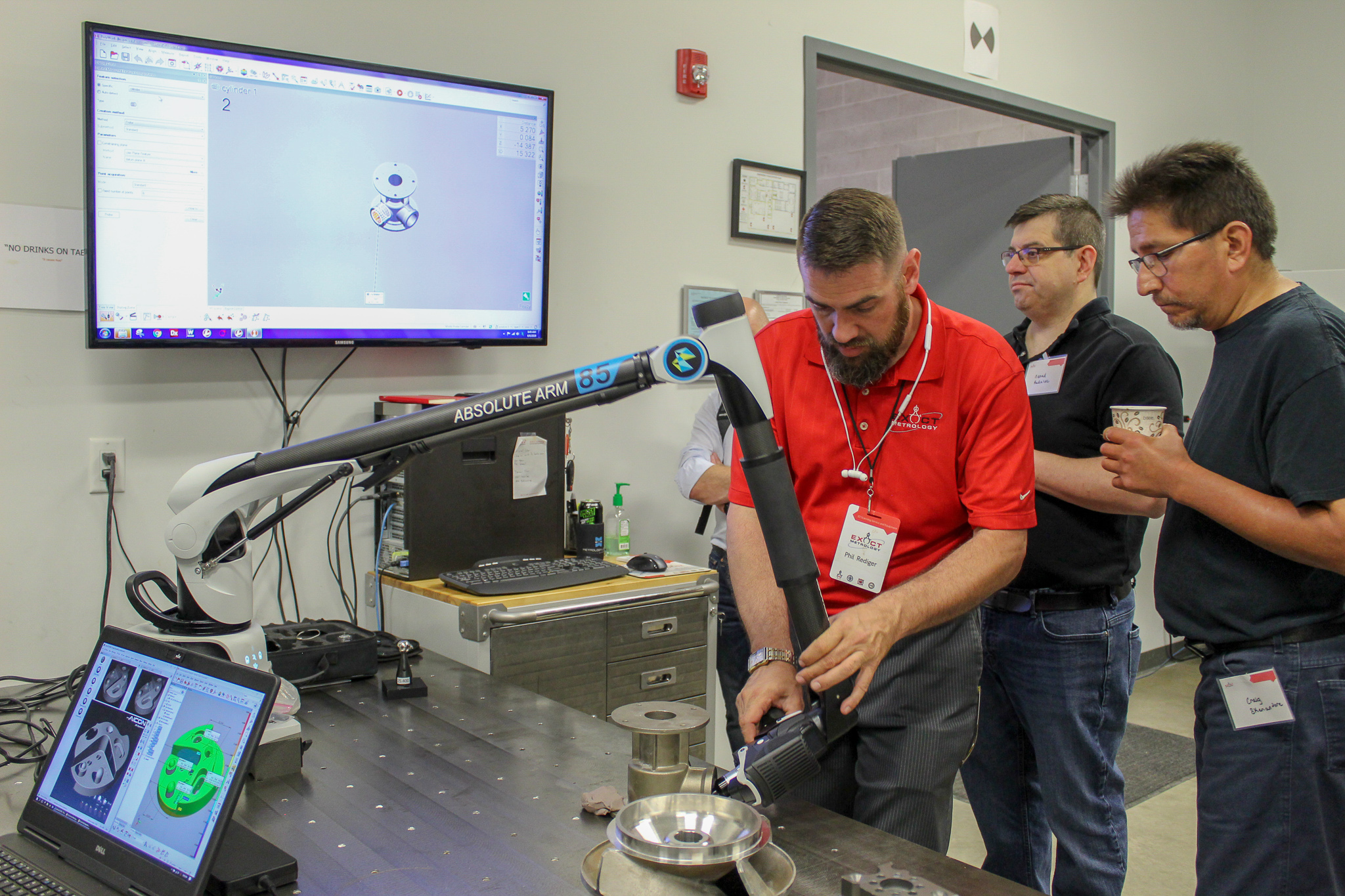

This location will serve as a training, support, contract measurement and sales center. Training will be provided on software packages such as: PolyWorks, Geomagic and PC-DMIS. The Polyworks software suite maximizes productivity, quality, and profit, while integrating 3D measurement technologies into an industrial manufacturing process. Geomagic is a leading provider of 3D software that creates digital models of physical objects for industries like aerospace, archeology, medical, dental, tooling and foundry. Provided by Exact Metrology through Hexagon Metrology, PC-DMIS offers the most popular dimensional metrology software package. Hardware classes will be offered for Romer, Leica Tracker, Superphaser, Leica RTC 360 and a CMM. Manufactured by Hexagon Metrology, the Romer portable measuring arms offer reliable 3D measurements. Leica Laser Trackers are ideal for measuring medium to large parts and providing a portable solution for large-scale inspection and assembly applications. The Superphaser line provides short, medium and long range models for use in reverse engineering, dimensional control, historical preservation, architecture and forensics. Leica RTC empowers users to document and capture environments in 3D, improving efficiency and productivity through fast, simple-to-use, accurate and portable hardware and software. Lastly, Exact Metrology will also offer a complete range of portable Coordinate Measuring Machines (CMM) and custom classes for any measurement needed. Day classes and half day classes will be available.

Contract services that will be offered include CMM measurement, custom programming, inspection and reverse engineering. Inspection is important because when a part is defined by millions of points, users can see subtle deviations, slight variations and fine details, thus ensuring that a part or mold meets certain specifications. 3D inspection is recommended for first article inspections, first-off inspections (sampling), in-process inspections, die tryouts, tool and die duplication and statistical sampling. Reverse engineering is not only used for product design but also for legacy part repair and re-manufacturing, product benchmarking, documentation and archival, site planning, defect/deterioration documentation, medical devices and custom-fit products.

“Exact Metrology can add support and service to our customers in western Illinois and Indiana. We hope to keep growing the customer base in this area,” says Joe Wright of Exact Metrology.