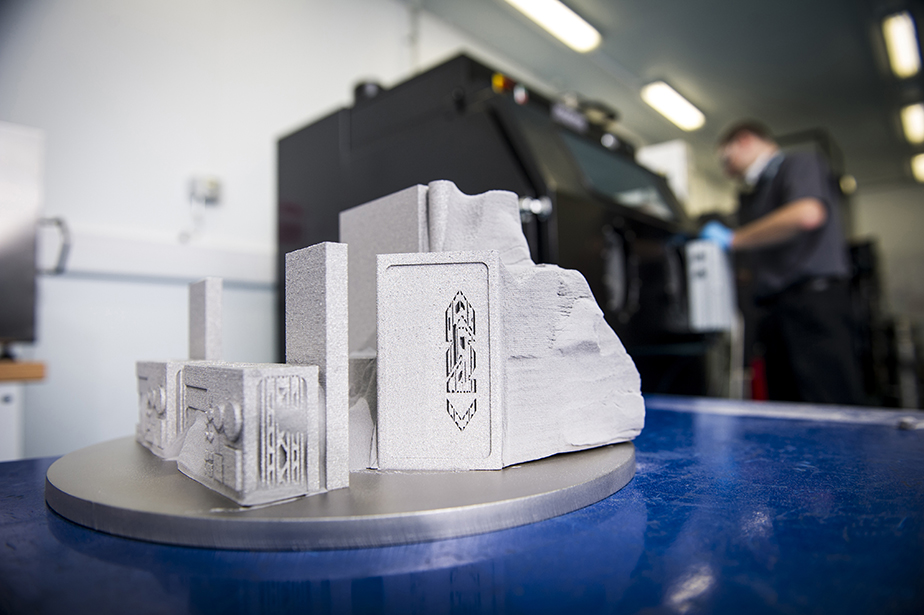

PARIS AIRSHOW, Le Bourget: GKN Aerospace and Saab are celebrating one year of collaboration in additive manufacturing. The partnership between GKN and Saab has already resulted in the delivery and certification of AM components now flying on Saab aircraft. The partnership with Saab has focused on metallic powder bed technology, delivered from GKN’s centre of excellence in Filton, in the UK. Further developments will push the boundaries of the AM processes by introducing new materials and designs whilst simultaneously continuing to reduce the production lead times and costs.

GKN Aerospace has seven global centres of excellence providing expertise from fine-scale deposition to large-scale laser wire capabilities. GKN has polymer and metallic AM parts flying on seven major platforms across multiple markets: commercial, military, rotorcraft and space. It produces these components from AM centres of excellence in the UK, the US, Sweden, Germany and the Netherlands.

John Pritchard, GKN Aerospace’s CEO of Aerostructures Europe and China said:“Saab is a long-term, valued customer for GKN and partnering with them on this ground-breaking new technology has been a major success for both companies. Historically, the challenge for AM was to move it from theory into production: fully certified and flying on major platforms. We are well past that stage now – AM is out there and flying on aircraft around the world today. I am confident that this partnership will push the boundaries of this revolutionary technology further in the years to come.”

Photo: Additive Manufacturing at GKN’s facility in Filton, UK