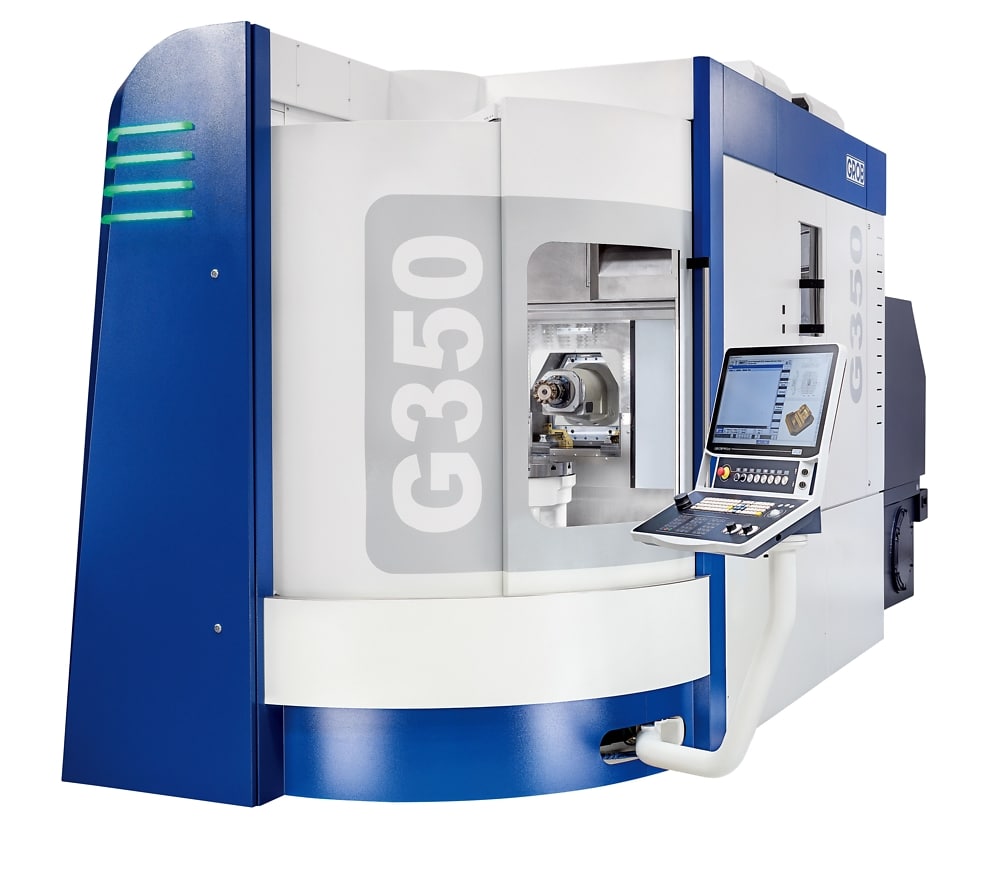

GROB Systems, a developer of manufacturing systems and machine tools, highlights its second-generation G350 5-Axis Universal Machining Center, featuring a compact design, maximum milling performance, high visibility, and optimized work area access. The GROB G350 is ideal for use in aerospace, die and mold industries, or medical applications.

The GROB Systems G350 Universal Machining Center delivers high productivity, optimum availability, and excellent maintenance access. What’s more, it features a unique machine concept; three linear and two rotary axes permit 5-axis simultaneous machining and simultaneous interpolation. The machine’s unique axis arrangement permits upside down machining, offering almost limitless possibilities for part machining. Meanwhile, the horizontal spindle position permits the longest possible Z-travel path and optimum chip fall.

The unique arrangement of the three linear axes minimizes the distance between the guides and the machining point (TCP), lending the machine considerable stability. Thanks to the machining center’s special axis concept, the full tool length can be employed in any axis position, even with maximum part size. This “tunnel” concept provides the basis – even with extremely long tools – for being able to swivel and machine the largest possible component within the work area without collision.

With a swivel range of 230 degrees in the A’-axis and 360 degrees in the B’-axis, the G350 offers the greatest possible positioning flexibility, while the machine bed’s intrinsically stiff welded design delivers optimum machine rigidity. The G350 also features absolute position encoders, an air purge seal in all linear and rotary axes, and a disk-type tool magazine for fast tool change.

The central, ergonomic arrangement of the machine components guarantees optimal accessibility to the fluid cabinet and electrical cabinet, as well as easy access for preventive maintenance and inspection.