The Naval Air Warfare Center Aircraft Division (NAWCAD) recently patented a suite of corrosion mitigation products aimed at solving naval aviation’s billion-dollar corrosion problem.

Chemists from NAWCAD developed Navguard, a family of aircraft cleaning, coating, and lubricant products to prevent rust and mildew on aircraft and their components – a problem that cost the Navy over $2 billion for the F/A-18C-G fleet alone from 2017-2020.

“Corrosion is almost like a cancer,” said NAWCAD chemist, Dr. El Sayed Arafat. “If nothing is done to stop it, it keeps going until it’s too late to fix – Navguard improves readiness for the Navy and the rest of the DOD.”

Navguard is a first-of-its-kind corrosion inhibitor for the DOD. It has a longer shelf life, is easier to apply, and lasts longer than existing corrosion prevention products on the market. It is also safer for the environment. Navguard is in service with squadrons across the fleet today.

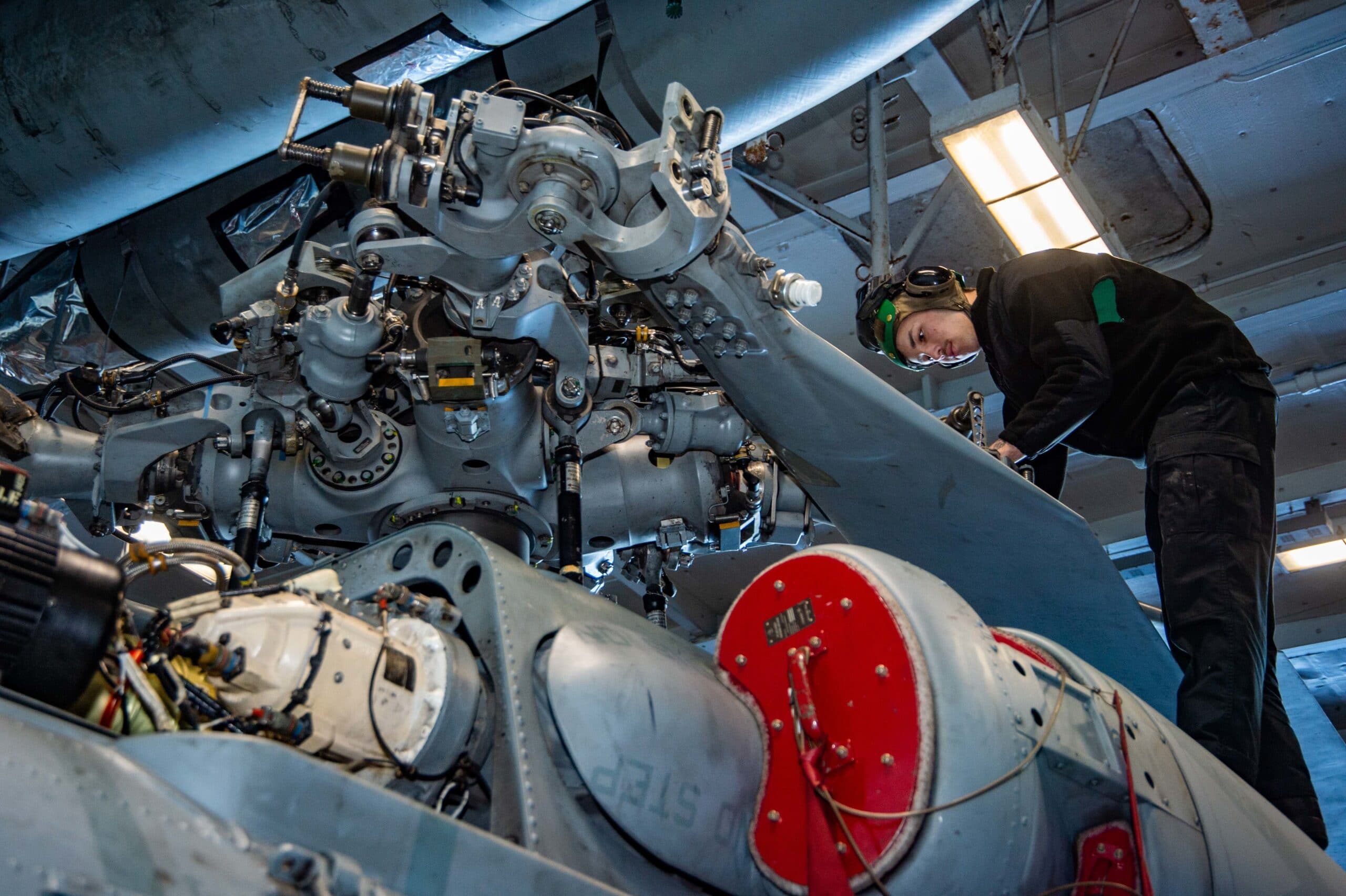

NAWCAD has been leading the corrosion campaign since the Navy identified corrosion as the single greatest systemic degrader across the fleet. The command, working with other Naval Air System commands, has implemented a number of additional systemic mitigation initiatives to address the problem, including establishing a corrosion monitoring process across the DOD’s fleet of aircraft, and instituting Navy-wide training to improve aircraft maintainers’ approach to corrosion mitigation.

The Naval Air Warfare Center Aircraft Division is the Navy’s largest warfare center, employing more than 17,000 military, civilian and contract personnel. It operates test ranges, laboratories and aircraft in support of test, evaluation, research, development and sustainment of everything flown by the Navy and Marine Corps. Based in Patuxent River, Maryland, the command also has major sites in St. Inigoes, Maryland, Lakehurst, New Jersey, and Orlando, Florida.