JB Roche introduced a new approach to the way engines will be protected from this point forward.

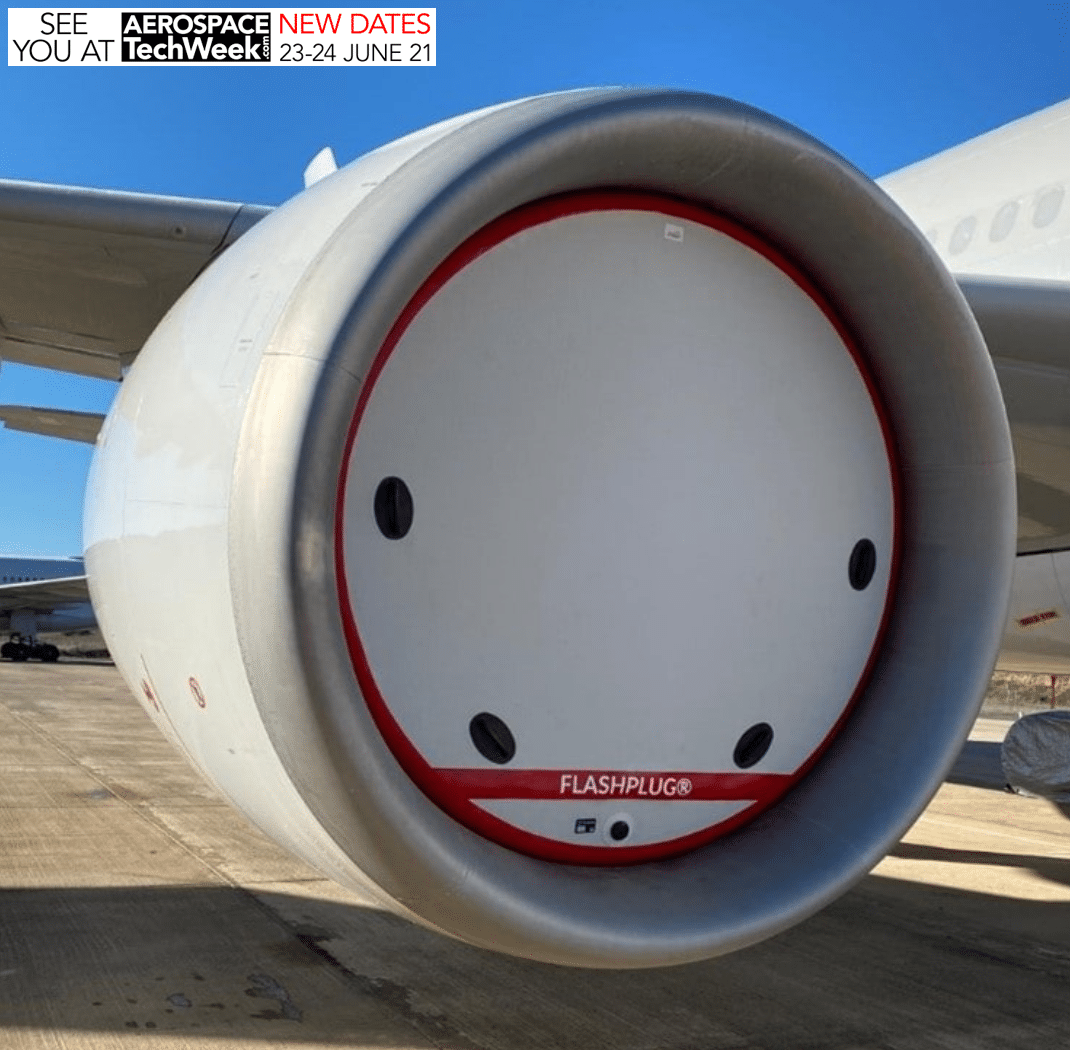

FLASHPLUG AIR can be fitted to your aircraft in about three minutes by one mechanic. There are no buckles, clips or straps needed to hold it in place and no ladders or steps are required to install it. There are no internal metal frames which risk scratching your intake and no bulky foam sections which need to be dried out after a wet spell of weather.

Conventional covers can trap moisture leading to corrosion risks and a poorly fitted cover can create more harm than good by damaging your lip skin or livery. This risk is heightened when storing aircraft for extended periods.

FLASHPLUG AIR on the other hand is installed inside the delicate lip skin area and creates an airtight seal at the front of the engine, according to the company. When used in conjunction with our FLASHPLUG LITE exhaust engine blanks, this unique preservation solution will keep your engines at Relative Humidity levels of under 50 percent. Such relative humidity levels have previously been impossible to achieve in the case of engines stored on-wing. However, this game-changing design will now allow operators to maintain their powerplants in an ideal storage configuration without incurring the cost of engine removal and storage.

FLASHPLUG AIR kits are supplied complete with a storage bag, installation instructions, on-site repair kit, and Schrader valve adaptor as standard. An integrated Bluetooth Humidity Sensor that connects to a phone app is available as an optional extra for added peace of mind.

To purchase the safest, fastest and smartest engine preservation systems on the market please contact us or our global sales partners:

Satair, HYDRO Systems KG, Eirtech Aviation Services

FLASHPLUG AIR is part of the FLASHPLUG family of preservation products developed by JB Roche.