Spectrum Metrology has launched a handheld gauging system into the UK for rapid micro-defect/corrosion analysis directly on the shop floor. The 4D INSPEC micro-defect inspection gauge (designed and manufactured by U. S. company 4D Technology) measures defects in 3D on large or complex parts such as inside bores, under flanges and in tight corners.

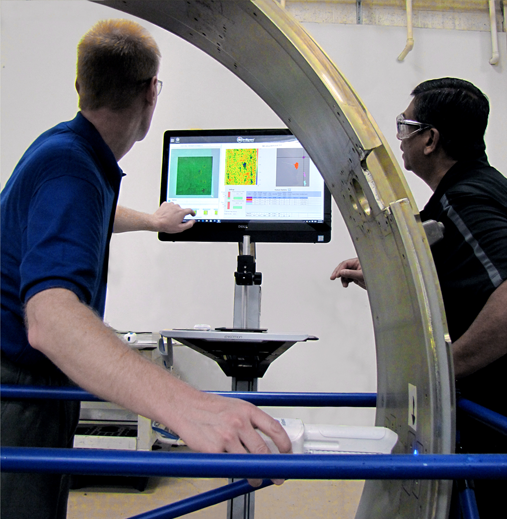

Traditionally, measurement of surface defects on the shop floor has been a choice between a subjective visual check or a time-consuming lab inspection. Using a patented camera technique for stability, the 4D Inspec is completely portable, allowing quick measurement, directly on the shop floor without the need for time-consuming replicas or dismantling of large parts.

The 4D Inspec reduces scrap, decreases inspection cycle times and improves reporting.

The 4D INSPEC gives real data for 3D micro-measurement, quantifying pits, scratches, nicks, dents, bumps, porosity and corrosion on parts with complex geometries such as turbine blade sections (without the need for replication), engine components and drive train components. The system identifies features from 5µm-2mm deep over a field of view of 8x8mm (10µm-9mm over 15x15mm with the XL model).

Spectrum Metrology is the authorized UK distributor for this gauge and is offering demonstrations of its capabilities.