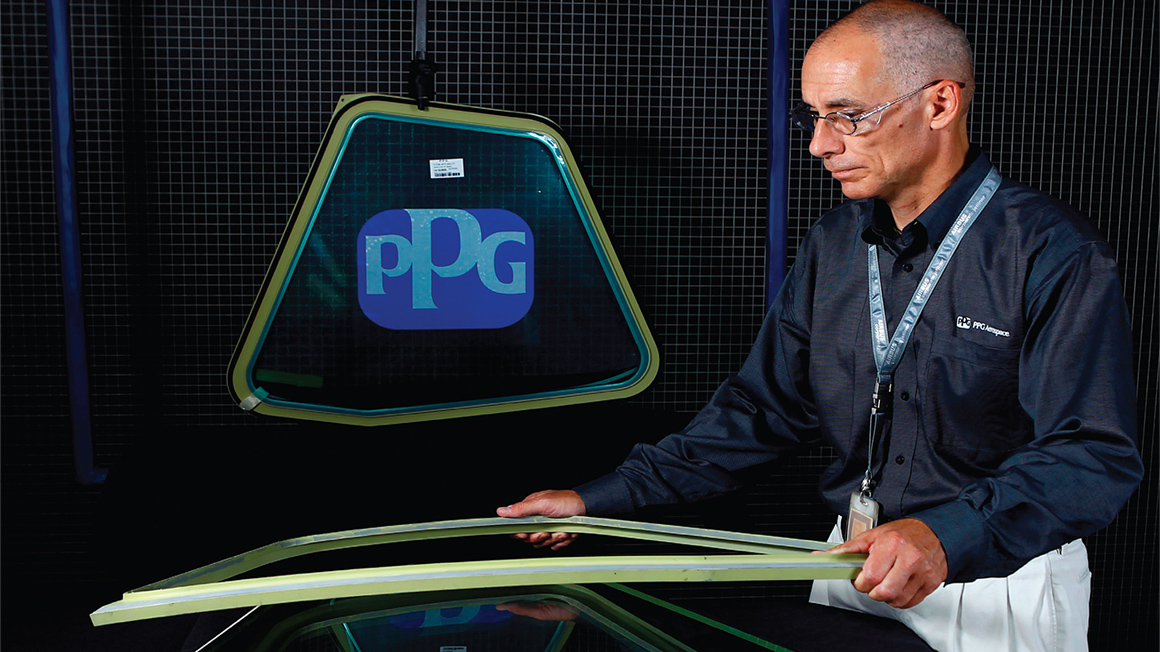

PPG Industries’ aerospace transparencies group has introduced redesigned sliding cockpit windows for the Airbus A320 Family that are expected to have improved field performance over the previous design and afford cost-effective replacement.

The new windows have passed successfully all ground and flight tests in PPG and Airbus facilities. They can be used for original- equipment and replacement applications on Airbus A318, A319, A320 and A321 single-aisle airplanes as well as the NEO (new- engine option) Family that includes the A319neo, A320neo and A321neo airplanes.

PPG’s redesigned aft fixed side cockpit windows were qualified by Airbus in 2012 with similar enhancements. A new simplified clamp design for the windows enables the frame retainer and window panel to be installed as a complete assembly while being distinct components. Operators can now salvage undamaged PPG frame retainers for reuse when only window panels need to be replaced. PPG offers replacements of the complete framed window assemblies consisting of the frame retainer and window panel as well as window panels for installing in salvaged PPG frame retainers.

According to Arthur Scott, PPG global director for commercial aerospace transparencies, PPG has continued to improve performance of the windshields and side cockpit windows for the A320 Family since it was certified to supply them in the 1990s.

To defend against moisture ingress and delamination, the redesigned side cockpit windows have an added stainless steel Z-retainer, proprietary PR-2060 polyurethane sealant as an internal sealant behind the Z-retainer and S-123 urethane interlayers.

PPG’s redesigned windshields for the A320 Family, which it introduced in 2010, incorporate S-123 urethane, PR-2060 sealant, PR-1425CF chromate-free sealant and an improved electrical system. According to Scott, thousands of aircraft are flying with the new-design windshields. “These windshields are demonstrating service life more than double that of the previous design, resulting in lower operating costs.”