With millions of workers injured and killed annually in hazardous industrial workplace environments, Sentinel Occupational Safety Inc., a new venture-backed startup, is introducing its ‘Safety as a Service’ platform known as SafeGuard to improve workplace safety through more preventive oversight.

SafeGuard’s unique IoT approach combines sensors, wearables and AI analytics to intelligently and continuously monitor workers in a variety of dangerous occupational settings. From frontline firefighters and construction workers who face excessive heat, smoke, and pollution on the job, to those working inside dangerous confined spaces in the presence of noxious fumes, chemicals, and other hazards, workers face far greater risk of injury or death when inadequately monitored, working alone or remotely.

One hundred occupational fatalities each week are deemed preventable. Work-related injury and illness cause 500+ million annual lost workdays.*

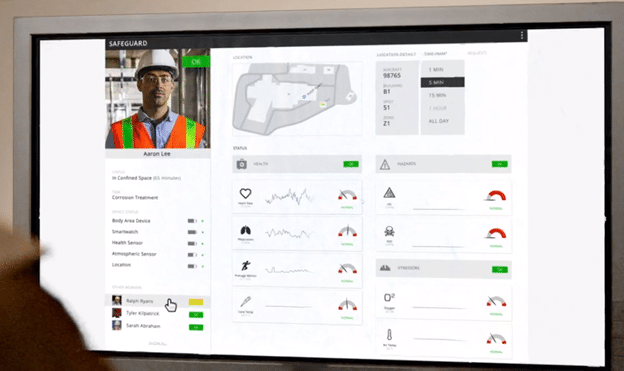

SafeGuard fuses a combination of environmental, human, and locational data from a worker’s sensors, analyzing it in the cloud and at the edge to provide real-time detection and alerting. For a mechanic welding inside a ship compartment, for example, algorithms assess their physiological, atmospheric, and other indicators, including heart rate, breathing, air quality, and motion, detecting risks such as dangerous levels of fuel vapors or low oxygen, and their health status.

Unlike current safety protocols that rely on one-to-one observers to check in with confined space workers at intervals, SafeGuard’s cloud-based monitoring enables a single safety manager to oversee the real-time health and safety of 15-20 workers simultaneously, even tracking their precise locations in GPS denied environments.

Predictive alerts and intuitive at-a-glance “green-yellow-red’ status indicators provide continuous, comprehensive monitoring for proactive injury prevention. In the case of high risk or man-down situations, SafeGuard’s built-in decision support capabilities facilitate the appropriate intervention, including emergency or medical response when seconds and minutes are crucial.

Funded by Aptima Ventures and the Dayton-based Accelerant Fund, Sentinel is commercializing an innovative ‘confined space monitoring system’ originally developed to improve real-time incident detection and safety oversight for U. S. Air Force aviation maintainers. It is also expected to boost Air Force productivity, allowing nearly 80 percent of personnel previously used in 1:1 worker monitoring to be freed up for other work.

“We’re excited to take innovative technology designed to protect military personnel and transition it to the urgent safety needs of workers in the wider industrial market,” said Zachary Kiehl, CEO of Sentinel Occupational Safety. “Through the remarkable partnership of the US Air Force, Aptima, and Lockheed Martin, we were able to realize the lifesaving potential of fusing together wearable sensor data, AI analytics, to personalize worker safety monitoring in relation to the job. SafeGuard not only better protects workers in dangerous jobs, it is also a workforce multiplier enabling better allocation of human labor.”

In addition to the inherent dangers of confined space jobs, the general trend toward increasingly dangerous work conditions are being exacerbated by global pandemics, climate change, heatwaves, and forest fires. In the case of first-responders, fire, and medical personnel, SafeGuard’s AI-based physiological baselining, contextualized sensing, and predictive alerting can monitor for heat stress, exhaustion, pollution and other conditions impacting worker health.

For lone and remote workers, such as utility and power grid personnel at risk from falls or electrical shock while far from others, SafeGuard’s motion- and fall-detection, and man-down alerts are uniquely suited to providing these vital monitoring and response needs.

The SafeGuard platform is sensor agnostic. The patented fusion engine technology and big data modeling can integrate and correlate nearly any sensor and data type to provide monitoring and predictive alerting for specific jobs and occupational safety requirements.

Because SafeGuard’s underlying technology was initially developed for stringent military application, its algorithms have been validated to prevent false positives. The Safety-as-a-Service platform employs encryption and other data security measures for transmission, cloud storage, and privacy requirements.

To view the SafeGuard video, visit: https://vimeo.com/412981108

*Statistics from OSHA, Dept. of Labor and Integrated Benefits Institute