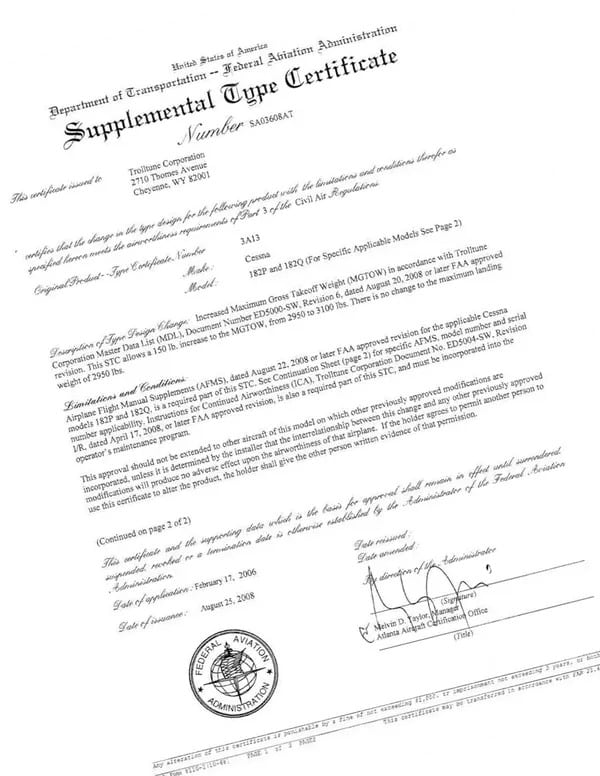

CustomCells, a leading innovator in the development of premium lithium-ion battery cells, announces its strategic move towards achieving Design Organization and Production Organization certifications from the European Union Aviation Safety Agency (EASA). This landmark initiative underscores CustomCells’ commitment to advancing the electrification of aviation and setting new standards for airworthy battery solutions. CustomCells is deepening its involvement in the e-Aviation ecosystem exhibition and conference season, starting by taking part in the aviation show “AERO Friedrichshafen” this week together with its partner VÆRIDION. Finally, the company’s new white paper will be presented there. Entitled “The Enabler of eAviation: Advanced Batteries for a Cleaner Sky”, CustomCells provides an overview of the status of current developments and how its high-performance battery cells will help electric flight achieve a breakthrough.

A Milestone for CustomCells

The pursuit of EASA certifications marks a significant milestone in our journey, reinforcing our dedication to excellence, safety, and innovation in designing battery cells that meet the rigorous demands of electric aviation applications. By meeting EASA’s stringent standards, CustomCells aims to provide the aviation industry with battery cells that offer unmatched reliability, performance, and safety. As we embark on this certification process, CustomCells is committed to transparency and collaboration with regulatory bodies, industry partners, and stakeholders.

Advanced Batteries for a Cleaner Sky

While the electrification of road transport is making steady progress, a comparable technological change in aviation has yet to materialize. Together with its customers, CustomCells is driving the transformation to environmentally friendly battery-electric drive systems – paving the way for sustainable and climate-neutral aviation.

“As a company dedicated to the development of advanced energy storage solutions, we are happy to share our insights and expertise with industry representatives, cooperation partners and the interested public – and with all aviation enthusiasts who, like us, have a vision of a sustainable, electrified future for air travel,” says Dr Dirk Abendroth, CEO of the CustomCells Group.

With the white paper, CustomCells provides an overview of the technological future of aviation. Particular attention is paid to the crucial role that lithium-ion batteries will play in the electrification of aviation. The paper outlines the current eAviation landscape and the highly dynamic development in this area, presents the different types of electric aircraft and the different battery form factors and also describes the certification of electrically powered aircraft.

The Central Part of the Electric Transformation of Flying

As one of the world’s leading developers and manufacturers of lithium-ion battery cells in the premium segment, CustomCells is significantly shaping innovations in the eAviation sector. “CustomCells is a pioneer and technological trailblazer in the battery industry. The electrification of aviation calls for innovative solutions that have not existed until now,” says Abendroth. “Our cutting-edge battery cell solutions are the key to unlocking the immense potential of electric flight and ushering in an era in which aircraft are emission-free, quiet and efficient. We are the co-pilots of the next century story.”

Eric Swedersky, Senior Vice President Commercialisation at CustomCells, adds: “The use of high-performance battery cells enables the next generation of flight – from electric vertical take-off and short take-off aircraft to conventional take-off and landing aircraft. For short distances, the first battery-electric aircraft of this type are already in the starting blocks, equipped with state-of-the-art battery cell technology from CustomCells – including Lilium and VÆRIDION, for example. This opens up a completely new segment of urban and regional mobility.

Sustainable, digital and electrically powered eAviation offers innovative solutions for modern mobility requirements. CustomCells is driving this development forward with high-performance, German-engineered battery cells.”