Robinson Helicopter Company (RHC) has acquired Ascent AeroSystems, now a wholly-owned subsidiary of the Robinson Helicopter Company. This acquisition reinforces Robinson’s dedication to scaling innovation, accelerating new rotorcraft developments, and supporting diverse missions worldwide. By leveraging the expertise and resources of both companies, Robinson reinforces its leadership in the future of vertical flight systems and utility missions.

Ascent AeroSystems, recognized for its efficient and compact coaxial helicopter drones designed for industrial, public safety, and defense applications, brings a wealth of technological synergies that align with Robinson’s strategic vision for growth and expansion into new markets. Through the acquisition, Ascent can now grow and scale by building its UAVs at Robinson’s cost-effective, vertically integrated manufacturing facility in Torrance, CA.

Ascent AeroSystems’ expertise in autonomous electric flight technology and modular design philosophy will enhance Robinson’s offerings. The integration of emerging technologies and a diverse ecosystem of payloads, power sources, and launch methods will further enhance the company’s mission-focused offerings, including crewed-uncrewed teaming and interoperability across product families.

“This strategic acquisition is in line with our vision to broaden our offerings and meet increasing global demand for enhanced mission capabilities in law enforcement, public safety, firefighting, utility, and defense,” said David Smith, president and CEO of Robinson Helicopter Company. “Ascent’s advanced technologies and versatile designs complement our ability to be the preeminent choice in global rotorcraft.”

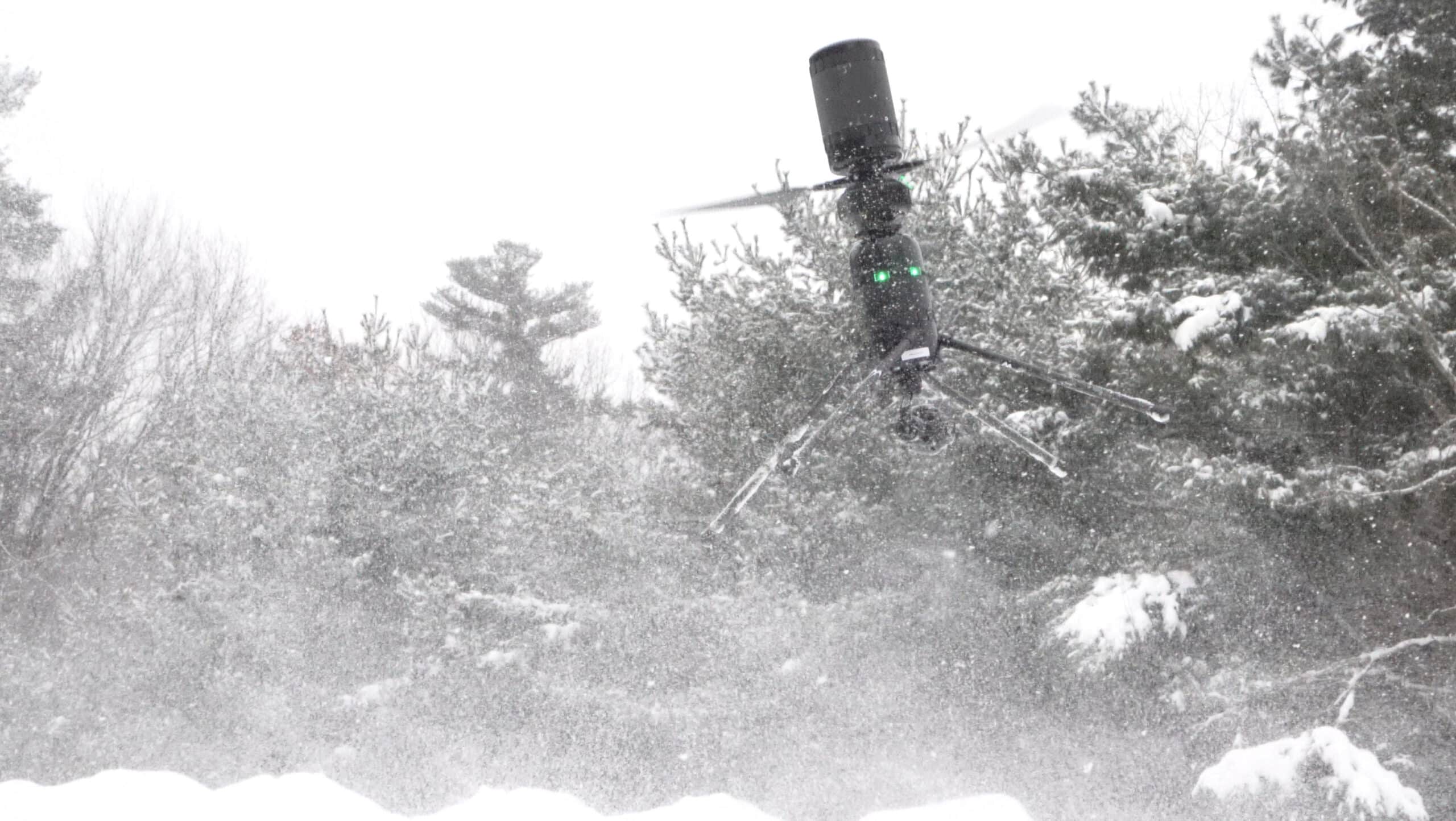

Ascent AeroSystems’ unique cylindrical, coaxial airframes stand out from competitors in each weight class, offering unparalleled flight performance, payload capacity, and reliability compared to conventional multirotor configurations. Included on the Defense Innovation Unit’s (DIU) Blue UAS Cleared List, the flagship Spirit is a compact, modular, rugged, all-weather platform engineered to operate reliably in the most challenging environments, including high wind, heavy rain, sleet, snow, and blowing sand. The larger NX30 offers more than twice the payload capacity in a heavy lift variant, or it can be configured with additional batteries for flights exceeding an hour.

“Drones based on consumer-grade electronics will never be able to provide the safety and dispatch reliability needed to support operations at scale,” said Peter Fuchs, Ascent AeroSystems’ CEO. “They will ultimately require a type certificate for the aircraft, a production certificate for the factory, an operating certificate for the network, and a maintenance certificate for the repair station. That is the standard that has provided the foundation for civil aviation for the last eight decades. It’s a rigorous process, and there are no shortcuts. The laws of physics and aerodynamics favor coaxials, and with Robinson’s fifty years of experience, there is now no better domestic source for reliable, mission-critical UAV platforms.”

UAS are increasingly integrated into traditional rotorcraft operations in sectors including defense, public safety, agriculture, energy, utilities, construction, logistics, shipping, and surveying. Ascent AeroSystems will maintain its headquarters near Boston.