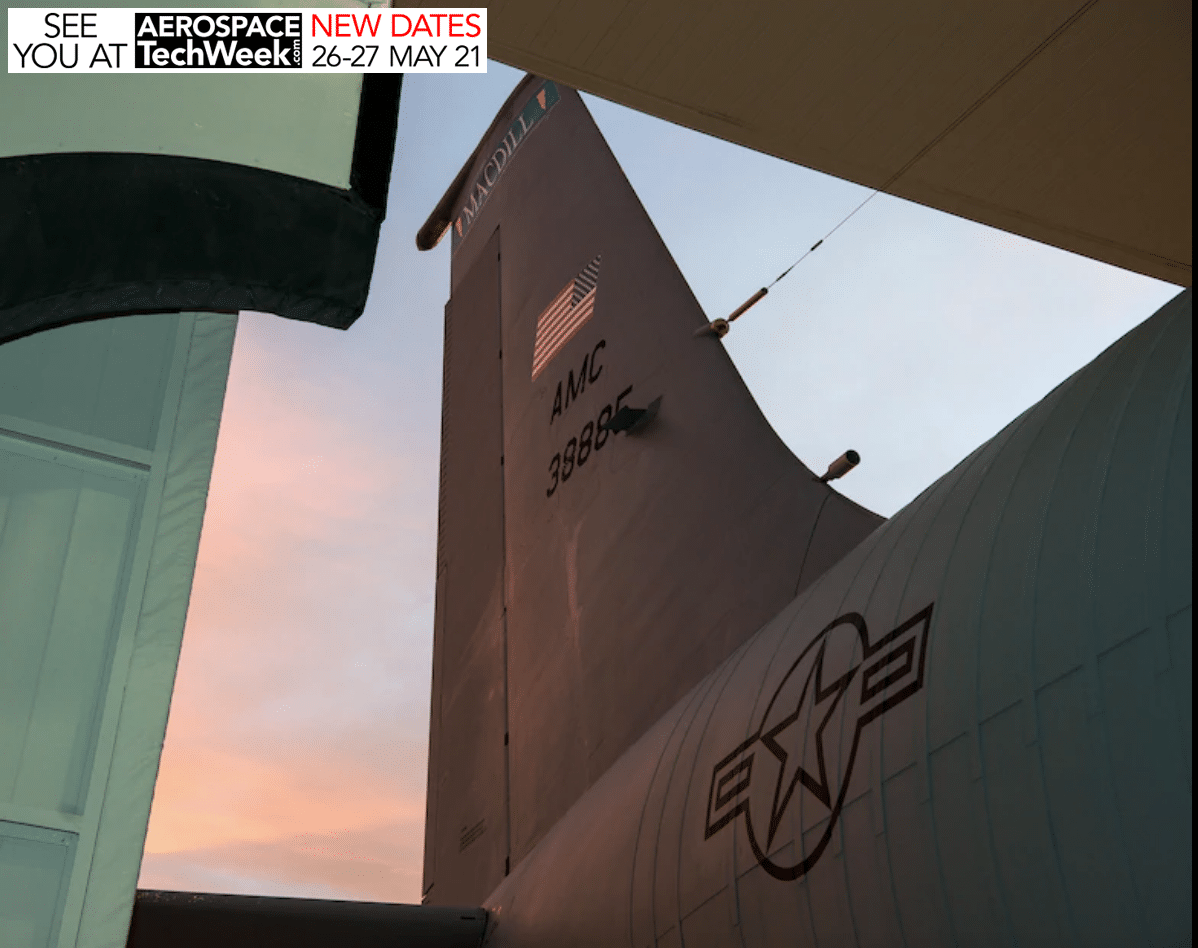

Tucked away behind U.S. Central Command and MacDill Air Force Base’s traditional hangars lies a hangar originally built to house fighter jets. On a given day, peeking out of that hangar will sit a KC-135 Stratotanker aircraft seemingly out of place in the considerably smaller maintenanc e shop, but surely, it’s in the right hands.

e shop, but surely, it’s in the right hands.

This hangar is the home of the 6th Maintenance Squadron’s fuels systems section. “Tank Divers,” as the technicians of this shop are called, work day and night to ensure MacDill AFB’s aircraft are always ready to fuel the fight.

Fuels technicians handle all operations involving the pumps, valves, manifolds and all aspects that encompass the fuel cell, which the Tank Divers view as the heart of the aircraft. The system is made up of massive, black bladders that hold jet fuel within the wings and run down the bottom of the KC-135 fuselage. Maintaining these cells takes a special group of Airmen willing and capable to contort and fit themselves into the body of this aircraft.

“We’re well-trained and well-versed in how to do anything on the fuel system,” said Staff Sgt. Dakota Williamson, a 6th MXS fuel systems craftsman. “I like to say the fuel is the blood of the system and all of its workings are its veins. You can’t have a well-oiled machine without it, so without us, you can’t fly.”

When a fuel leak is reported, fuels technicians must assess the damage to the cell, like a medic triaging a patient. Fuel is intended to remain in the bladder, so if it is found in the aircraft body cavity, Airmen perform tests to inspect for damage. Airmen remove the bladder from a hole not much bigger than a shoebox, pump it up with air pressure and then test with either a chemical or bubble solution to uncover any impairment.

“It’s important to maintain the cells and make sure they’re in the best condition they can be,” said Airman 1st Class Brendon Kozicki, a 6th MXS fuel system journeyman. “We make sure all components are working as they should be and fix anything that would keep it out of the sky.”

As with any job involving harmful chemicals, fuels comes carefully procured safety regulations to ensure the Airmen are safe when they go diving. Before climbing into the aircraft fuel cell, Tank Divers don personal protective equipment such as coveralls, head covers, gloves and air respirators to avoid harm from the chemicals they encounter.

“The process of opening a fuel tank is very dangerous and can present an explosive environment,” Williamson said. “People don’t really get to see much of what we do or where we go because when we open that tank up, we can’t have anything that produces a spark or is not intrinsically safe (nearby). Our hangar is set up to be 100% safe and fireproof.”

Though the Tank Divers call the hangar their home, they also must complete facets of their work on MacDill AFB’s flightline.

“Since we’re considered a back shop, we also go out to our alternate location on the opposite end of the flightline,” Williamson said. “To mitigate going back and forth, our team here designed a trailer that would house everything we need to be out on a job and take shelter from the elements.”

There’s a sense of pride amongst the Tank Divers about their careers; they are the chosen few to do a unique job that puts them in tight places no one else gets to see or experience.

“My favorite part of my job would be fixing the jet myself and knowing I did something to fix what was keeping the jet out of the sky,” Kozicki said. “It feels great working together to figure out what is wrong with a jet and seeing the outcome of it being out and ready to fly again.”

Through strength and flexibility, MacDill AFB’s Tank Divers maintain the hearts of all 24 KC-135s assigned to the base.