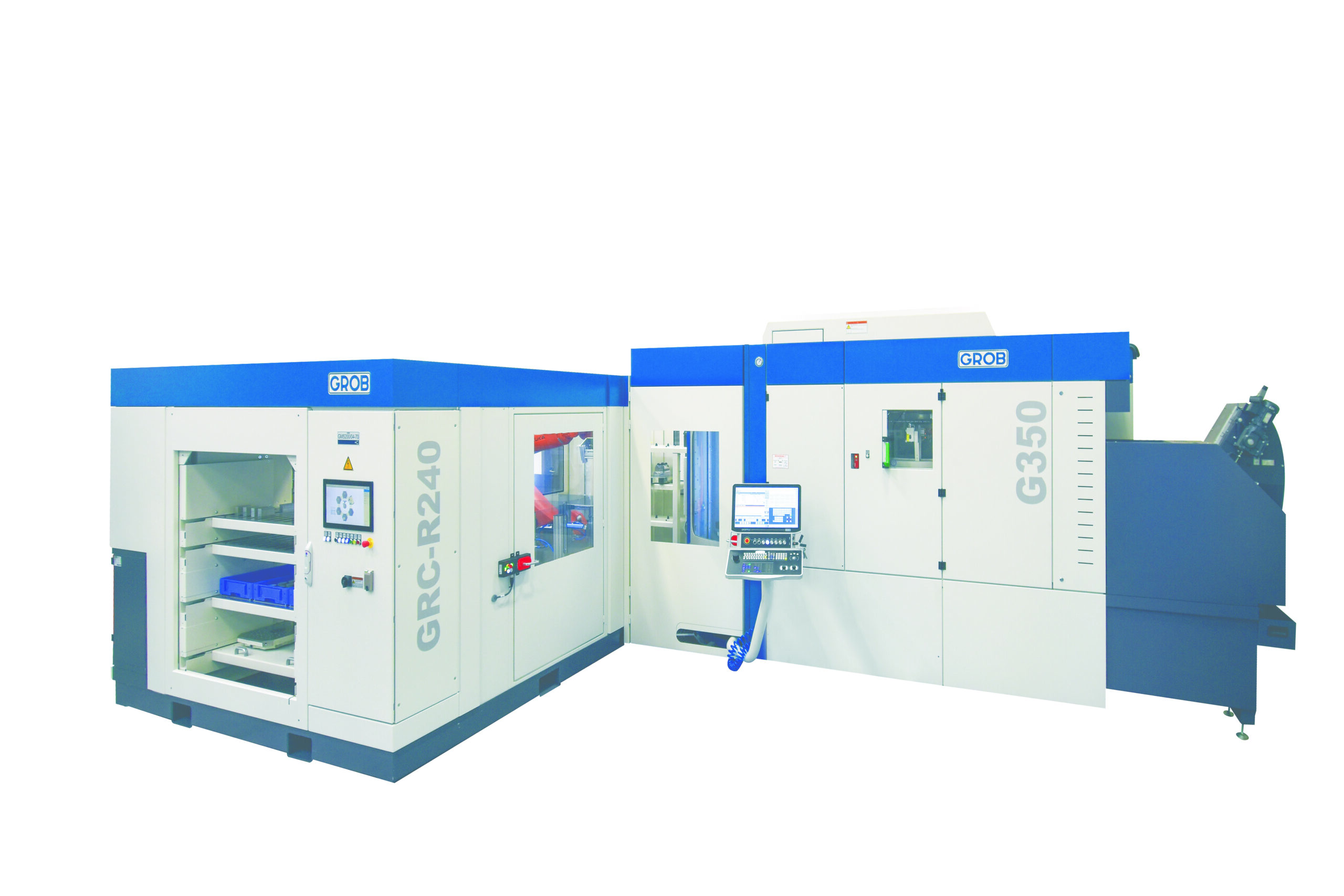

GROB Systems, makers of manufacturing systems and machine tools, announced the availability of the new GROB robot cell (GRC), which combined with the company’s G-modules, provides maximum flexibility and customization for manufacturing of aerospace, mold & die, medical, and many other industry applications.

The company says the GRC offers a complete solution from a single source, with a uniform design and coordinated interfaces. This solution is capable of part handling as well as pallet handling which allows for maximum flexibility.

The compact design of the GRC has a shared base frame enabling quick and easy installation; the standardized software allows the cell to be commissioned quickly. The innovative feeding system with part drawers enables longer unmanned production. In addition, an automatic clamping fixture and part gripper change is available for different clamping fixtures and part types.

The connection to GROB’s production control software GROB4Automation allows for flexible planning and management of work orders resulting in improved production sequences. The GROB robot cell can also be configured with a variety of modules, depending on customer requirements such as deburring, washing and measuring all in the same cell. The GRC can also be expanded to feed multiple machining centers.