Pexco Aerospace (Pexco) announced its AirShield technology, designed to prevent airborne germs and odors entering the personal space of every airline passenger, has received STC certification from the Federal Aviation Administration (FAA) for use on the A320 family of narrowbody aircraft.

What is AirShield?

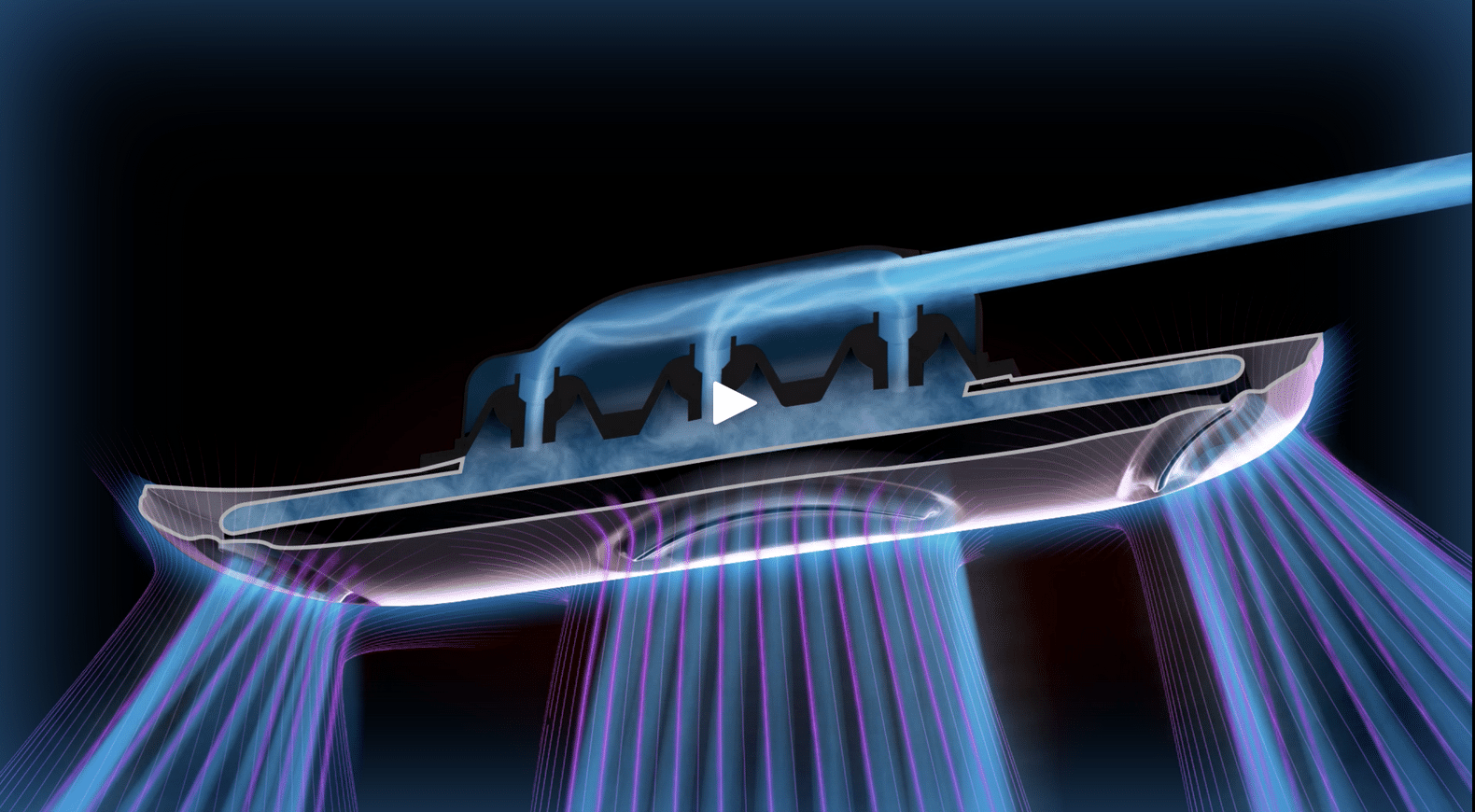

Retrofitted over the existing passenger air vents above every seat, AirShield works in harmony with existing HEPA filtration systems to create protective air barriers between and around every passenger in the cabin, restricting unwanted germs and odors from entering their personal space. It maximizes passenger wellbeing by reducing shared air by at least 76 percent (in a full narrowbody cabin with no facemasks) and increases the speed at which contaminated particles are expelled and replaced by freshly purified air by 230 percent.

Droplets from each breath, sneeze, and cough are captured, contained, and sent down to the HEPA filters before they reach other passengers or flight crew – something of extreme importance given the proximity of people in a narrowbody cabin.

Rigorous research

Pexco completed one of the most comprehensive independent assessments of cabin airflow (using more than 60 million data points of computational fluid dynamics) to maximize the design and performance of AirShield. This included undertaking on-wing tests in collaboration with major airlines and aircraft lessors, including American Airlines, Southwest Airlines, Alaska Airlines and Avolon.

Pexco’s research demonstrated aircraft cabins are highly efficient at exchanging and cleaning the air in considerable volumes, with the HEPA filtration system removing bacteria and viruses as the air passes through. But existing airflow in narrowbody aircraft sees airborne particles and odors – that could potentially be contaminated with viruses from stray breaths, coughs, or sneezes – inadvertently pulled across neighboring passengers’ seats before exiting through the HEPA filters. AirShield prevents this cross-contamination from happening.

Since the inception of AirShield, Pexco has invested in more than 8,000 subject matter expert person-hours, generated more than 60 million data points of CFD, created more than 30 prototypes for more than 100 lab tests, and completed 22 on-wing tests in the aircraft of three major airlines to ensure AirShield has the efficacy to set a new gold standard for passenger wellbeing in the narrowbody cabin.

Engineering expertise

As part of the rigorous FAA certification process, Pexco engineered AirShield to be extremely durable – able to withstand abuse and manual interference, while also streamlined enough not to obstruct passengers’ line of sight to emergency signage and lighting. AirShield does not impact smoke evacuation of the existing HEPA filtration system, and as each AirShield is not located in the ‘head strike’ zone, there is no need for airlines to recertify their seats.

AirShield is extremely lightweight (weighing less than a pound) and engineered to be simple to manufacture and quick to install. With its unique design, consisting of a three-piece clip-together assembly, each installation takes less than a minute and an entire aircraft can be completed during standard overnight aircraft maintenance. The design also benefits airlines who lease aircraft as they can remove AirShield equally as quickly, with no remodifications needed to the aircraft to return it to its original state.

As an additional layer of hygiene protection, Pexco also uses an antimicrobial additive to manufacture AirShield. This destroys 99.99 percent of bacteria (even antibiotic resistant strains such as MRSA, VRE and CRE) upon contact – supporting airlines and OEMs to maintain high standards of hygiene onboard.

Anthony Ciringione, Vice President of Sales & Marketing at Pexco Aerospace, comments: “In the last twenty years the global airline industry has faced SARS, Swine Flu, MERS, as well as COVID-19 and influenza. If history teaches us anything, there will be another airborne pandemic or epidemic – it is only a matter of time. We need a fresh approach to passenger wellbeing in the cabin, implementing long-lasting and proven innovations that improve hygiene onboard today, so it is effectively prepared for what will come tomorrow.”

Passengers keen to fly AirShield

An independent passenger survey ² of leisure travelers in the United States has showcased the growing demand for AirShield:

· 91 percent agreed that AirShield makes them feel like an airline is taking care of them.

· 89 percent would feel more comfortable flying with AirShield post-pandemic.

· 86 percent of respondents also stated they would choose to fly with an airline with AirShield installed over one without.

· 71 percent would also pay more for a ticket if an airline equipped its planes with AirShield.

By preventing unwanted odors from entering passengers’ personal space, AirShield enhances the inflight experience by offering a ‘virtual distance’ in the cabin where a physical one is impossible. While it reshapes air flow, AirShield does not alter the cabin’s temperature or the volume of air supplied, and air is not blown directly onto passengers’ faces or bodies but around them – creating a protective cocoon. The technology is even 50 percent quieter than standard aircraft air filters, helping create a relaxing ambience onboard.

“Bringing blue-sky innovation to the cabin interior is a challenge that requires investment of time, money, and engineering expertise. Achieving FAA certification was the last hurdle for AirShield. There is now nothing stopping airlines using AirShield to enhance the inflight experience and protect the personal space of millions of passengers who step onboard every day – something economy travelers have wanted for a long time,” adds Page.

Pexco is currently in discussions with airlines across the US, Europe, and Asia with the aim of having AirShield installed on A320 aircraft in early 2023 – supporting the continued recovery of the airline industry and its long-term focus on enhanced passenger wellbeing in the cabin. Pexco is also exploring certification options for AirShield on other narrowbody aircraft types, including the B737, as well as line-fit versions of its technology.