Pratt & Whitney held a groundbreaking ceremony for its new 845,000 square foot facility in Oklahoma City, Okla. As part of the project announced in March, Pratt & Whitney is investing $255 million in the new facility, which will act as a hub for depot support for Pratt & Whitney military engines maintained at Tinker Air Force Base and other depot locations, including those for the F-35, C-17, F-22, F-15, F-16, B-52, and E-3 AWACS.

The groundbreaking ceremony was attended by key local leaders, including Rep. Tom Cole (OK-04), Rep. Stephanie Bice (OK-05), Sec. John Nash, Councilman Todd Stone, and representatives from Sen. James Lankford’s, Sen. Markwayne Mullin’s, Gov. Kevin Stitt’s, and Mayor David Holt’s offices.

“Aerospace and defense play a major role in Oklahoma’s economy and growing workforce, and I’ve been glad to see Pratt & Whitney be a key asset to the industry over the past several decades,” said Governor Kevin Stitt. “It is great to see Pratt & Whitney choose to invest and expand their operations in our great state, and I look forward to continuing to make Oklahoma Top Ten for aerospace and defense.”

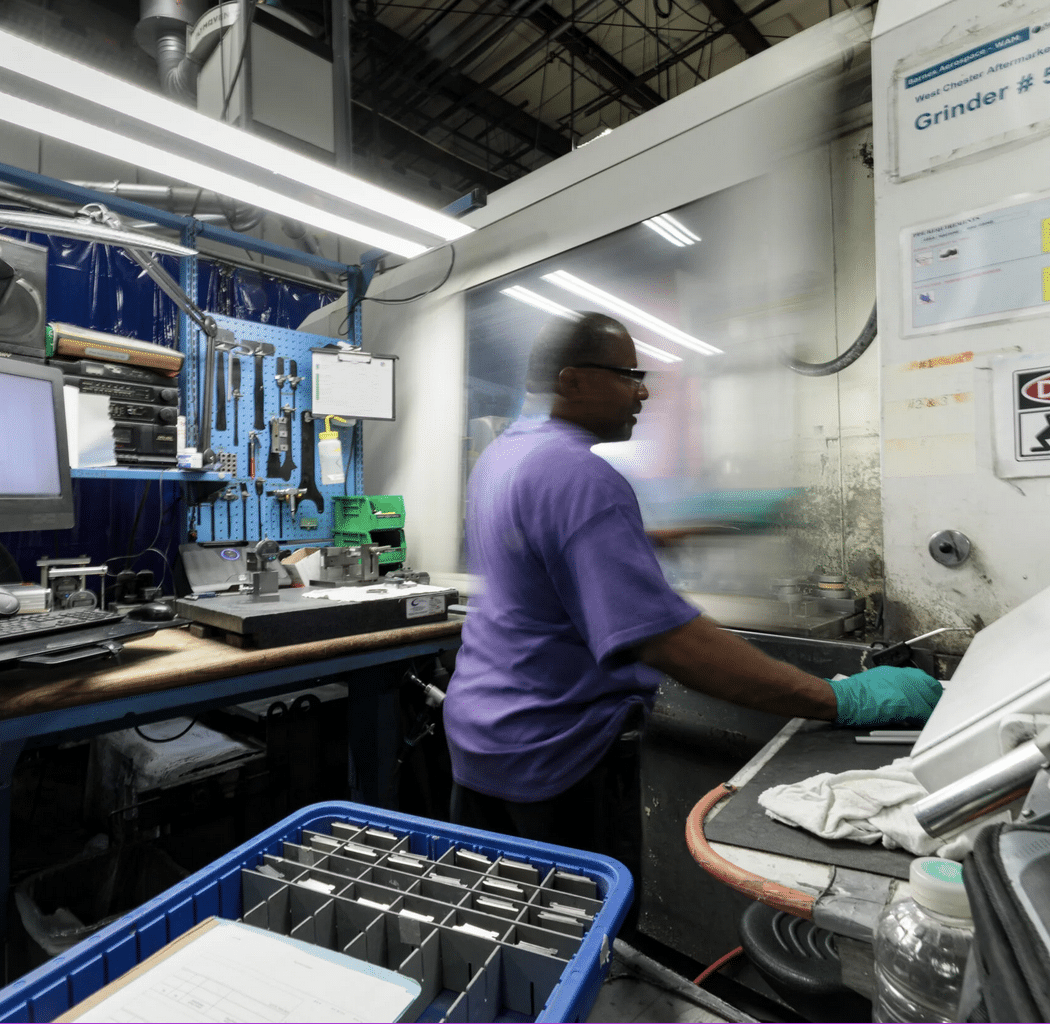

Pratt & Whitney has deep roots in Oklahoma City dating back to the 1940s, when the Army established a depot for the C-47 Skytrain and its R-1830 Twin Wasp engines. Today, Oklahoma City is the heart of Pratt & Whitney’s global sustainment network and plays a critical role in many of the company’s most important military engines programs, achieving record output from the F117, F119, and F135 Heavy Maintenance Centers in 2022.

“With strong demand for our newer products such as the F135 engine for the F-35 fighter – which is about to enter its first scheduled maintenance cycle – and increased operational tempo for other engine programs to help protect U.S. national security interests, we have continued to grow our presence in Oklahoma City to ensure we have the right people, processes, and infrastructure in place to keep pace,” said Jill Albertelli, president, Pratt & Whitney Military Engines.

Once complete, the new facility will expand the company’s current sustainment capacity in Oklahoma City while consolidating six existing sites into two locations: the new Pratt & Whitney Oklahoma City facility and Tinker Air Force Base’s Air Logistics Complex.

“Pratt & Whitney is a trusted partner for military engine sustainment which enables wartime readiness and provides our armed services the competitive advantage needed to win,” said Congressman Tom Cole, OK-04. “Pratt & Whitney’s Oklahoma City site is the only depot capable of performing all F135 power module scope levels for the F-35, and expanding its capacities is the right decision as the military begins adopting the new F135 Engine Core Upgrade.”

Pratt & Whitney’s Engine Core Upgrade (ECU) is an upgrade for the F135 that will provide an affordable, low-risk, and agile pathway to enabling Block 4 capabilities for all F-35 customers. The ECU leverages Department of Defense investments in propulsion technology to deliver the advanced capability needed for Block 4 and beyond, while maintaining the variant-commonality and international partnership approach upon which the joint program was built.

“I am especially pleased that Pratt & Whitney is expanding their operations in the state,” said Congresswomen Stephanie Bice, OK-05. “Not only will this expansion bring more valuable jobs to Oklahoma, but more importantly, our servicemen and women will have better sustainment support that will help them complete their missions and return home safely.” Pratt & Whitney employs more than 450 full-time employees and an additional 450 partner contractors in Oklahoma City across disciplines including engineering, operations, finance, data analytics, materials and logistics, quality, and procurement. The new facility, which will be comprised of offices, meeting and collaboration spaces, storage and procurement facilities, and engineering workspaces, is expected to be fully operational by the end of 2024.