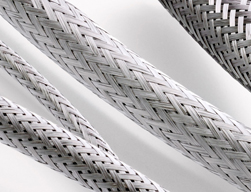

TE Connectivity (TE) announced its new Raychem INSTALITE lightweight braid system that the company says offers up to 50 percent weight savings over traditional copper braids. Made from a high-performance, nickel-plated copper alloy, the RoHS-compliant pull-on braid provides better low-frequency performance than plated fibers or microfilaments. Existing low-weight screening solutions are more limited with reduced electrical screen performance at low frequencies and lower protection against lightning strike. Plated fibers and microfilament stainless steel braids are more expensive options.

TE Connectivity (TE) announced its new Raychem INSTALITE lightweight braid system that the company says offers up to 50 percent weight savings over traditional copper braids. Made from a high-performance, nickel-plated copper alloy, the RoHS-compliant pull-on braid provides better low-frequency performance than plated fibers or microfilaments. Existing low-weight screening solutions are more limited with reduced electrical screen performance at low frequencies and lower protection against lightning strike. Plated fibers and microfilament stainless steel braids are more expensive options.

“Electromagnetic interference (EMI) protection is an ever-increasing requirement in the aerospace industry, especially as system functionality is increasing with higher signal speeds,” said Doug Jones, product manager, Global Aerospace, Defense & Marine, TE. “The INSTALITE lightweight braid has the ability to save weight while providing a high level of EMI screening across a wide frequency range. Its economical price makes it an attractive option for designers.”

TE’s INSTALITE lightweight braid is available in 3mm to 20mm diameters and installs and performs as a traditional metal braid. The lightweight braid is flexible and easy to handle. It also uses existing installation and termination methods and equipment to make integration into current applications simpler, according to TE. The INSTALITE lightweight braid is provided on a former to offer easy installation on variety of substrates.