TE Connectivity Ltd. (TE) announced its Raychem matched impedance splices for aerospace applications. Designed to comply with MIL-PRF-32517 standard, the splices solve the problem of costly removal and replacement of damaged coaxial cable by allowing fast, easy in situ repairs that maintain characteristic impedance and other electrical properties of the system.

TE Connectivity Ltd. (TE) announced its Raychem matched impedance splices for aerospace applications. Designed to comply with MIL-PRF-32517 standard, the splices solve the problem of costly removal and replacement of damaged coaxial cable by allowing fast, easy in situ repairs that maintain characteristic impedance and other electrical properties of the system.

Coaxial cables are used extensively within aerospace and avionics systems, yet there has been no effective solution to repair such cables damaged during operational use. Until now, any affected cables within the airframe had to be disconnected, removed and then replaced, which was both time-consuming and costly.

“Our engineers have developed a solution that addresses this common challenge by matching the characteristic impedance of the cable itself and offering the greater capability of in situ repair,” said Janeann Avants, product manager, Global Aerospace, Defense & Marine, TE Connectivity. “Our Raychem matched impedance splices reduce the time and effort needed for repairs and lessen the number of cables that need to be replaced.”

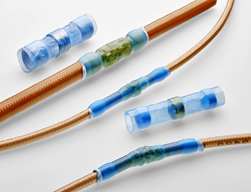

TE’s new Raychem matched impedance splices are designed for the harsh environments of military and commercial aerospace applications and are well suited for extreme temperatures, high vibration, high EMI and corrosive environments. The splice contains three components: a hexagonal crimp barrel for the center conductors, a dielectric shell that helps maintain cable geometry for impedance control, and a heat-shrinkable SolderShield splice that both terminates the cable’s shield and provides sealing to protect the splice environmentally.